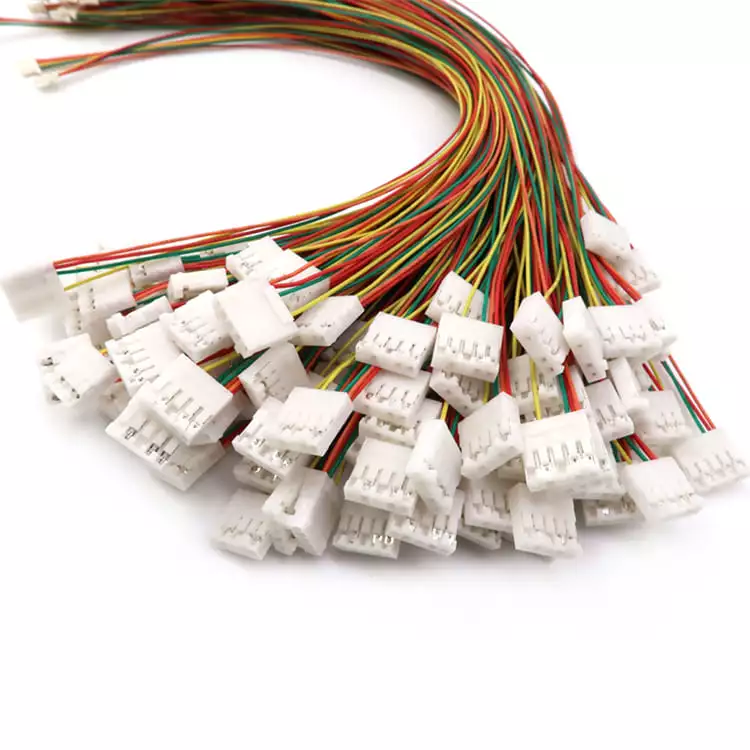

Wire harness and cable assembly manufacturer in China

About Us – Your Trusted Automation Partner

We provide customers with full-link support from design and development, precision processing to global supply.

12+

Photovoltaic Equipment Installed

48

Cities Connected

80+

ADAS Installed

999+

Satisfied People

Partnering with Industry Leaders Worldwide

Trusted by small factories and global industries for unparalleled automation solutions.

Why choose Linkwings Electronic?

we are differnet in

Global leader in customized wire harnesses and cable assemblies

As a professional manufacturer and supplier of wire harnesses and cable assemblies, Linkwings has a wide range of cable models. We have complete engineering, prototyping, and volume production capabilities to support flexible customization from 2-pole signal harnesses to multi-branch power harnesses. Whether you're in the automotive, industrial, medical, communications or new energy industries, we offer specialized connectivity products that meet your specifications and certifications.

Safety is our top priority

Every wire harness from Linkwings must pass 100% conductivity test, voltage test, insulation test and other tests before leaving the factory. The wiring harnesses are designed to meet customers' high requirements for safety and stability. Our products support RoHS, REACH, UL, ISO 9001 and other certifications, and some of our harnesses meet automotive grade or medical grade standards.

Fast Response and Global Service

We have a professional wire safety testing laboratory to ensure that we never compromise. We provide 3~7 days fast sampling service to support small batch validation and flexible mass production.

Discover linkwings Difference

It’s no accident that manufacturers around the world choose Linkwings as a top manufacturer of wire harnesses and cable assemblies. From automotivexi to consumer appliances and everything in between, our wires have been earning trust in more than 100 countries for more than 20 years.

Ready to take your cable and wire safety to the next level? Keep reading to find out why Linkwings is the wire harness and cable assembly manufacturer of choice.

What Our Clients Have to Say

Don’t just take our word for it. After ordering our wire and cables in bulk, manufacturers from every continent have given us five-star reviews for safety, durability, quality, and more.

Our Happy Clients:

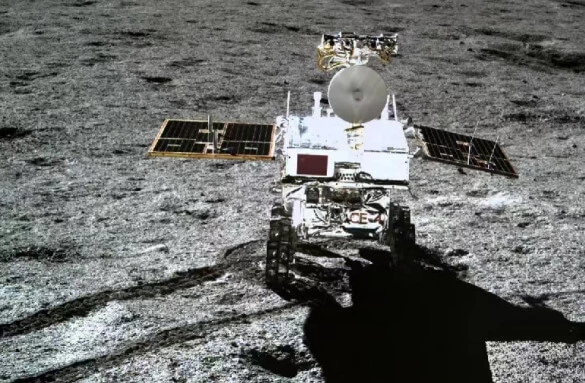

Cross-industry wire and cable solutions

Over the years, Linkwings has become the preferred wire and cable manufacturer for a wide range of industries. With our strong research and development capabilities, solutions can be customized as needed. At the same time, our technical team is always on hand to provide the after-sales support you need to thrive.

frequently asked questions

Transparency is the cornerstone of our Linkwings team. Therefore, you can find below the most frequently asked questions and answers we receive about wire harnesses and cable assembly solutions.

Do you support customization? How strong is the customization capability?

As a professional manufacturer of wire harnesses and cable assemblies, Linkwings can be personalized according to your drawings, samples or technical requirements. Including: cable structure (number of cores, length, shielding, etc.); connector type (Molex, JST, TE, customized plug, etc.); and wrapping method (heat-shrinkable tubing, snakeskin mesh, corrugated tubing, etc.).

How is the quality guaranteed? Is it certified? Can it be tested?

Our wire and cable products are certified to IPC/WHMA-A-620, ISO 9001, UL, RoHS, and more. And before your products leave the factory, we perform 100% conductivity test and voltage test. Even for automotive wiring harnesses, we can provide you with the perfect solution.

What is your production scale and equipment level? Can we cooperate for a long time?

Our factory covers 35,000 square meters and is equipped for automated, long-term deliveries. We are equipped with fully automatic wire cutting and stripping machine, terminal crimping machine, conduction test equipment, injection molding machine and so on. Therefore, we can meet the mass production of tens of thousands of wiring harnesses per day and support the flexible manufacturing of multiple varieties.

Are samples available? How long does it take to make a sample?

We support sample service, regular structures can be completed within 3~7 working days. Some of the customized structures may be charged with sample fee, which can be deducted in later orders. The samples are tested for conductivity and electrical testing to ensure that they can be used for assembly verification.