Home » 2.54mm Pitch Pin Header

2.54mm Pitch Pin Header – High Quality Connector Manufacturer | Linkwings

The 2.54mm Pitch Pin Header is one of the most common and highly versatile connectors, widely used in computer motherboards, communication equipment, industrial control systems, and automotive electronics. As a trusted 2.54mm Pitch Pin Header Manufacturer, Linkwings offers a full range of standard products and customized solutions to meet global customers’ demands for high quality and reliability.

Why Choose Linkwings as Your 2.54mm Pitch Pin Header Manufacturer?

As a professional 2.54mm Pitch Pin Header Manufacturer, Linkwings possesses years of experience in connector and wire harness manufacturing. Our product range encompasses a full spectrum of configurations including straight, SMT, angled, single-row, dual-row, and multi-row headers, with pin counts ranging from 2-pin to 100+ pins. We utilize high-quality copper alloy pins and offer multiple surface treatments including gold plating, tin plating, and nickel plating to ensure excellent electrical performance and long-term stability.

Linkwings prioritizes international quality standards and rigorous testing. All products comply with UL, RoHS, REACH, ISO9001, IATF16949, and ISO13485 certifications. They undergo insertion/removal endurance, electrical performance, temperature resistance, and vibration testing. Beyond standard products, we support custom designs and expedited delivery.

2.54mm Pitch Pin Header Types and Optional Configurations

The 2.54mm Pitch Pin Header, as one of the most standardized connectors, offers multiple types and configurations to meet the needs of various electronic products and PCB designs. Linkwings provides a full range of standard models and supports customized solutions for customers.

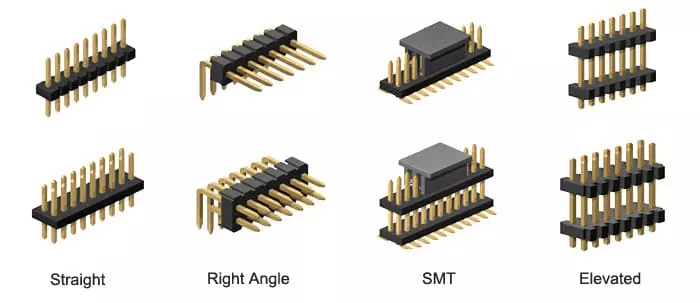

2.54mm Pitch Pin Header Types

Arrangement: Single-row, dual-row, multi-row configurations to accommodate varying signal channel densities.

Mounting Options:

- Through-Hole (THD): Suitable for traditional PCB soldering with high mechanical strength.

- Surface Mount Technology (SMT): Ideal for automated production with space-saving benefits.

- Right Angle: Used for specialized board-to-board connections or space-constrained applications.

Pin Configuration: Straight pins or round pins, selectable based on design requirements.

Optional Configurations

- Pin Count Range: 2 pins to 100+ pins, supporting both standard and custom configurations.

- Pin Material: High-quality copper alloy, ensuring electrical performance and durability.

- Surface Finish: Selectable options include Gold, Tin, and Nickel plating to meet diverse conductivity and corrosion resistance requirements.

- Plastic Housing Material: Engineering plastics such as PBT and LCP, with high-temperature versions available, suitable for reflow soldering processes.

- Special Customization: Supports non-standard pin shapes, custom pin counts, high-temperature versions, corrosion-resistant designs, and other personalized requirements.

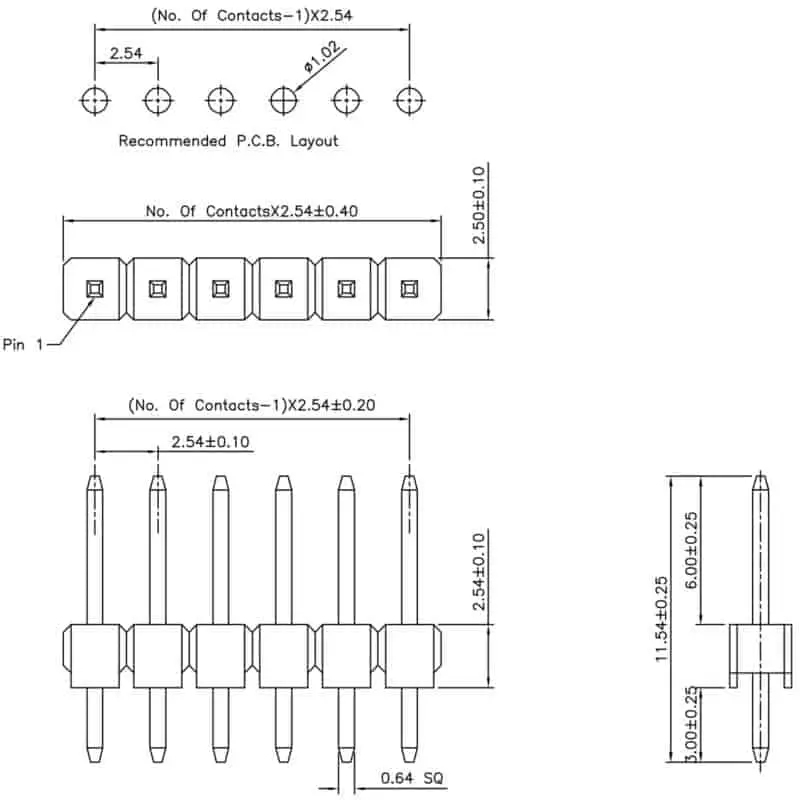

Specifications Table of 2.54mm Pitch Pin Header

| Category | Specifications & Features |

|---|---|

| Pitch | 2.54mm (0.1 inch standard) |

| Pin Count | 2Pin ~ 100+ Pin, customizable |

| Row Options | Single row, dual row, multi-row |

| Mounting Type | Through Hole (THD), Surface Mount Technology (SMT), Right Angle |

| Pin Material | Copper alloy |

| Plating Options | Gold plating, Tin plating, Nickel plating |

| Housing Material | Thermoplastic (PBT, LCP), high-temperature resistant versions available |

| Electrical | Rated current: 1A ~ 3A; Rated voltage: 100V ~ 250V; Contact resistance: <20mΩ; Insulation resistance: >1000MΩ |

| Mechanical | Mating cycles ≥ 500; Operating temperature: -40℃ ~ +105℃ |

| Compliance | UL, RoHS, REACH, IPC/WHMA-A-620, ISO9001, IATF16949 (Automotive), ISO13485 (Medical) |

2.54mm Pitch Pin Header Solutions

As a professional 2.54mm Pitch Pin Header Manufacturer, Linkwings offers customized design and production tailored to specific customer requirements, ensuring optimal performance and long-term stability across diverse application scenarios.

1. Consumer Electronics

Application Scenarios: 2.54mm Pitch Pin Header is widely used in computer motherboards, monitor interface modules, printers, home appliance control boards, and other devices. It primarily handles board-to-board connections for power and signals.

Challenges: Requires high versatility, excellent reliability, cost control, and support for long-term stable operation.

Linkwings Solution:

- Offers Through-Hole (THD) Pin Header with high mechanical strength, suitable for frequent insertion/removal;

- Provides tin-plated versions with high cost-effectiveness, ideal for mass production in consumer electronics;

- Complies with RoHS/REACH standards to meet environmental regulations.

2. Telecommunication Equipment

Application Scenarios: Pin headers are commonly used in routers, switches, servers, wireless modules, and other devices for high-speed signal and power interfaces.

Challenges: Ensuring signal integrity, interference resistance, and long-term durability for repeated insertion/removal.

Linkwings Solution:

- Offers dual-row or multi-row pin headers to increase signal channel density.

- Gold-plated pin versions are available, featuring low contact resistance and strong oxidation resistance, making them suitable for high-speed data signals.

- Signal integrity and EMI testing ensure stable transmission within communication equipment.

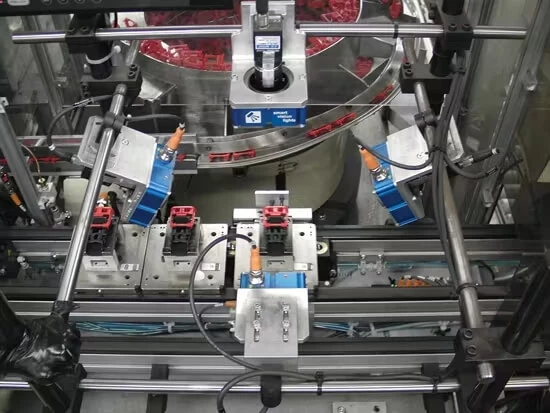

3. Industrial Automation

Application Scenarios: Pin headers are used for long-term module connections in PLC controllers, industrial control boards, robotics control modules, and testing equipment.

Challenges: Industrial environments expose connectors to high temperatures, vibration, and electromagnetic interference, demanding exceptional durability.

Linkwings Solution:

- Utilizes high-temperature-resistant LCP/PBT plastic housing materials suitable for reflow soldering processes;

- Offers angled Pin Header designs to optimize compact internal wiring within equipment;

- Complies with IPC/WHMA-A-620 industrial standards to ensure assembly consistency and reliability.

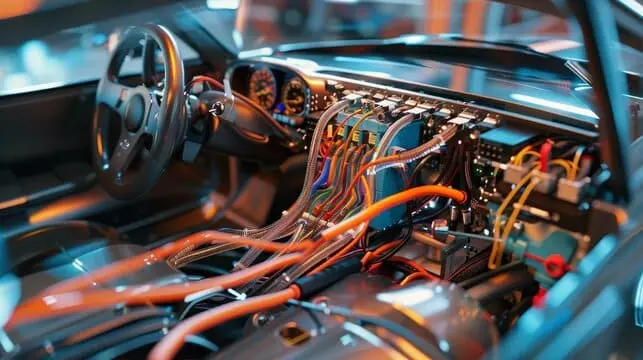

4. Automotive Electronics

Application Scenarios: In automotive control modules, instrument panels, infotainment systems, and vehicle sensors, pin headers are primarily used for signal acquisition and power distribution.

Challenges: Automotive environments feature wide temperature ranges (-40°C to +125°C) and frequent vibration.

Linkwings Solution:

- Provides automotive-grade Pin Headers certified under the IATF16949 quality system;

- Offers gold-plated pins to reduce contact resistance and enhance durability;

- Products undergo temperature, vibration, and insertion/removal life testing, making them suitable for automotive applications.

5. Medical Devices

Application Scenarios: Pin headers enable highly reliable, miniaturized circuit connections in patient monitors, ultrasound equipment, and portable diagnostic instruments.

Challenges: Medical devices must operate stably over extended periods while meeting safety and environmental standards.

Linkwings Solution:

- Provides high-precision pin headers to ensure stable signal transmission;

- Employs environmentally friendly and biocompatible materials compliant with ISO 13485 medical standards;

- Conducts rigorous reliability testing to guarantee long-term stability for medical applications.

FAQs

1. What is the difference between a 2.54mm pitch pin header and a 1.27mm pitch pin header?

Answer: The primary difference lies in the pin pitch. The 2.54mm pitch header is larger with greater mechanical strength, making it suitable for circuits requiring higher current and ample space. The 1.27mm pitch header is more compact, ideal for miniaturized designs and high-density routing.

2. What mounting options are available for your 2.54mm Pitch Pin Header?

Answer: Linkwings offers multiple mounting configurations, including Through Hole (THD), Surface Mount Technology (SMT), and Right Angle styles. We support single-row, dual-row, and multi-row layouts to accommodate diverse PCB design requirements.

3. What are the electrical characteristics of the 2.54mm Pitch Pin Header?

Answer: Typical specifications include: rated current 1A~3A, rated voltage 100V~250V, contact resistance < 20mΩ, insulation resistance > 1000MΩ. These specifications meet the requirements of most electronic and industrial applications.

4. Can we customize special pin counts or non-standard specifications?

Answer: Absolutely. We offer customization services for special pin counts, non-standard pin configurations, different plastic housing materials, high-temperature versions, and more, helping customers achieve optimal solutions for complex applications.