Home » 2mm Pitch Pin Header

2mm pitch pin header

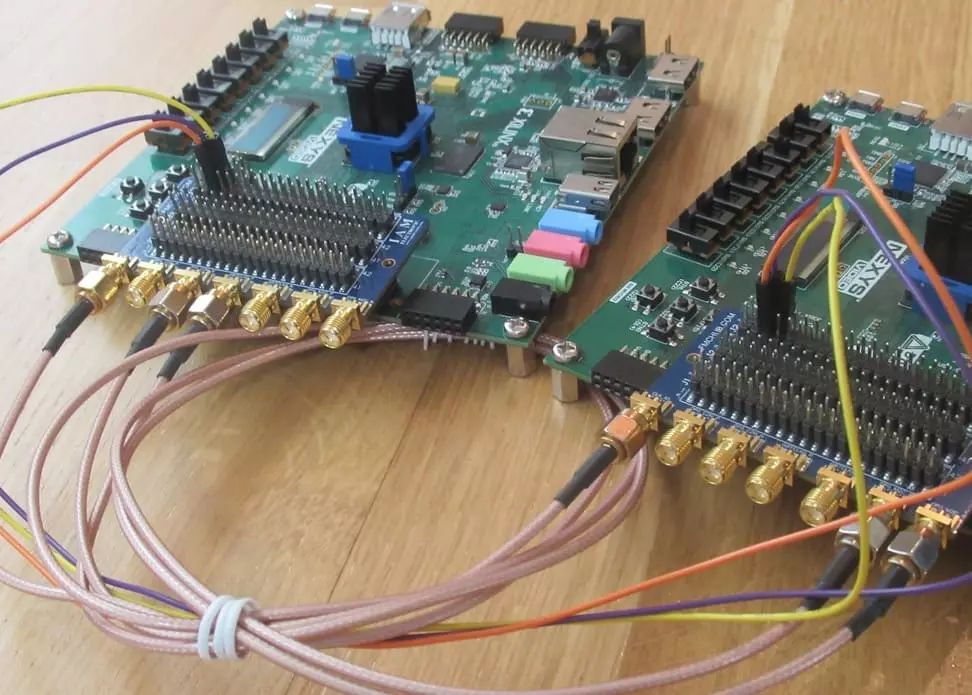

The 2.00mm pitch pin header is a commonly used board-to-board connector widely applied in industrial control, consumer electronics, automotive electronics, and communication equipment. Compared to traditional 2.54mm pitch headers, it offers a smaller footprint and more compact arrangement, making it ideal for circuit board designs requiring high-density mounting.

What is a 2mm Pitch Pin Header?

The 2.00mm Pitch Pin Header is a common electronic connector consisting of neatly arranged metal pins and an insulated base. It establishes reliable electrical connections between circuit boards or between a circuit board and other components. “Pitch” refers to the center-to-center distance between pins, and 2.00mm represents a compact design standard enabling higher density arrangements within limited PCB space.

Compared to traditional 2.54mm pitch pin headers, the 2.00mm variant occupies less space, making it suitable for miniaturized, highly integrated electronic devices. It can handle both signal transmission and medium-to-low current loads, commonly appearing in industrial control, consumer electronics, and automotive electronics. As such, it stands as one of the most frequently used standard connectors in modern circuit design.

Product Specifications of 2mm pitch pin header

| Parameter | Description |

|---|---|

| Pitch | 2.00mm |

| Rows | Single / Double / Triple |

| Pin Count | 2–40 (Customizable) |

| Mounting Type | Through Hole / SMT |

| Rated Current | 1.5A ~ 2.0A |

| Withstanding Voltage | 500V AC/min |

| Operating Temperature | -40℃ ~ +105℃ |

| Insulator Material | PBT / PA6T, UL94V-0 Flammability |

| Pin Material | Copper Alloy |

| Plating Options | Tin / Gold |

| Packaging | Tube / Tape & Reel |

Linkwings 2mm pitch pin header Solutions

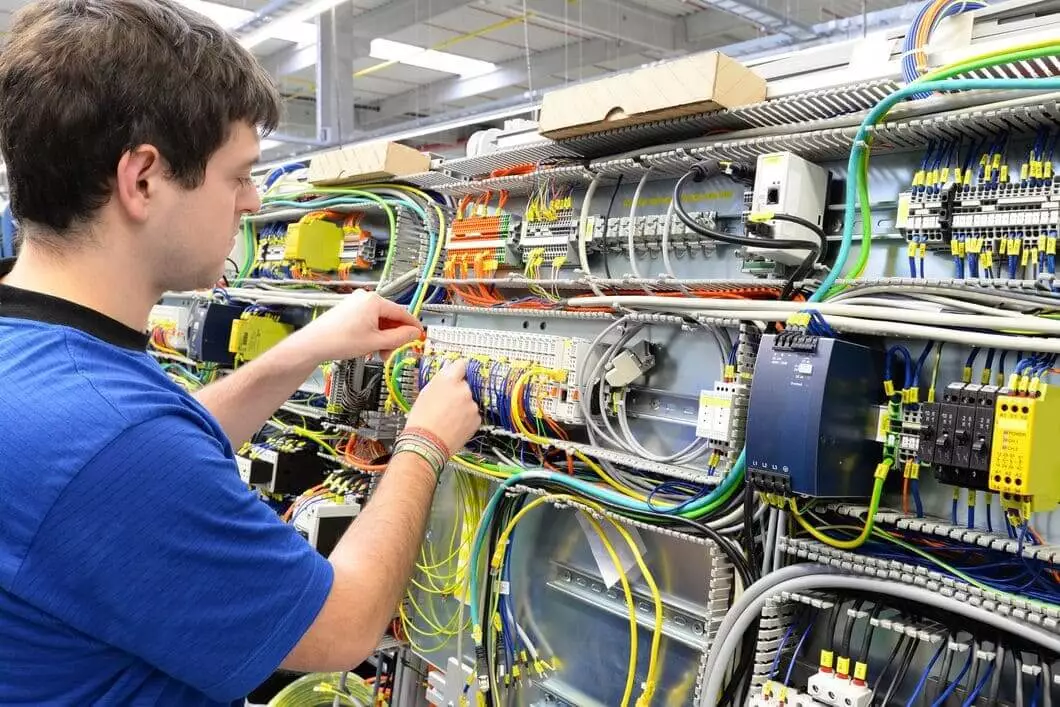

1. Industrial Control and Automation

In PLC controllers, sensor modules, and power control boards, 2.00mm Pitch Pin Headers are widely used for signal and power transmission. Their compact design enables high-density layouts within limited spaces.

Linkwings Solution: Offers PBT housing material with high-temperature resistance and flame retardancy, along with gold-plated pins to ensure long-term stable conductivity and vibration resistance.

2. Consumer Electronics

Products like tablets, digital cameras, and wearables demand slim designs. The 2.00mm Pin Header minimizes PCB footprint while ensuring reliable connections, making it ideal for highly integrated electronics.

Linkwings Solution: Offers SMT packaging compatible with automated placement processes, supporting mass production and boosting assembly efficiency.

3. Automotive Electronics

2.00mm Pin Headers are commonly used for signal transmission in vehicle control modules, body sensors, and infotainment systems. Automotive environments demand exceptional connector reliability and temperature endurance.

Linkwings Solution: Offers high-reliability Pin Headers compliant with IATF16949 standards, ensuring stable connections under extreme temperature cycling and vibration conditions.

4. Medical Devices

Portable monitors and diagnostic instruments demand strict specifications for connector size, stability, and insulation rating.

Linkwings Solution: Supports small-batch customization and gold-plating processes to ensure high-precision signal transmission, meeting the medical industry’s requirements for safety and long-term stability.

FAQs about 2mm pitch pin header

Q1: What is the difference between 2.00mm and 2.54mm pin headers?

A1: The primary difference lies in the pin pitch. The 2.00mm option offers a more compact design, saving PCB space, but demands higher manufacturing precision and assembly accuracy. The 2.54mm variant provides a more robust structure and is commonly used in traditional industrial and power supply applications. The choice depends on the product’s size requirements and application environment.

Q2: What specifications of 2.00mm pin headers does Linkwings offer?

A2: Linkwings provides specifications ranging from 2 to 40 pins, supporting single-row, dual-row, or triple-row configurations. Options include through-hole or surface-mount (SMT) mounting. We also offer tin-plated or gold-plated finishes to meet diverse environmental and performance requirements.

Q3: Can custom specifications be accommodated?

A3: Yes. Linkwings supports customization of pin count, row count, pin length, and plating type to meet specialized application requirements. Small-batch samples are available for testing.

Q4: How to select the appropriate Pin Header?

A4: Key considerations include:

- Space Requirements: PCB layout density and dimensional constraints

- Electrical Requirements: Rated current, voltage, and signal transmission quality

- Environmental Requirements: Need for high-temperature resistance, vibration resistance, or specialized plating

- Mounting Method: Select through-hole or SMT packaging