Custom Cable and Wire Harnesses

Get high quality custom cable and wire harnesses directly from the manufacturer.

Home » Custom Cable and Wire Harnesses

As a professional manufacturer of wire and cable connectivity solutions, Linkwings is committed to providing high-quality custom cable and wire harnesses for various industries, such as automotive, industrial automation, medical equipment, new energy and so on. We provide one-stop service from design, selection to production and delivery to ensure that the connection system is safe, stable and efficient.

With advanced production equipment and strict quality control system, Linkwings can realize multi-dimensional customization of conductor specifications, core structure, connector types, shielding methods, injection molding encapsulation, marking and coding, and so on. All products comply with international standards such as IPC/WHMA-A-620, ISO 9001, RoHS, etc., and are widely used in complex or harsh environments for long-lasting and reliable performance.

Linkwings serves OEMs and system integrators around the world, and supports prototyping and mass production with fast response time and technical support. Whether you are facing space constraints, high currents, signal interference or environmental challenges, Linkwings’ customized cable and harness solutions provide the best connectivity to support your system.

Custom Cable & Wire Harness Solutions

—— What we can offer you

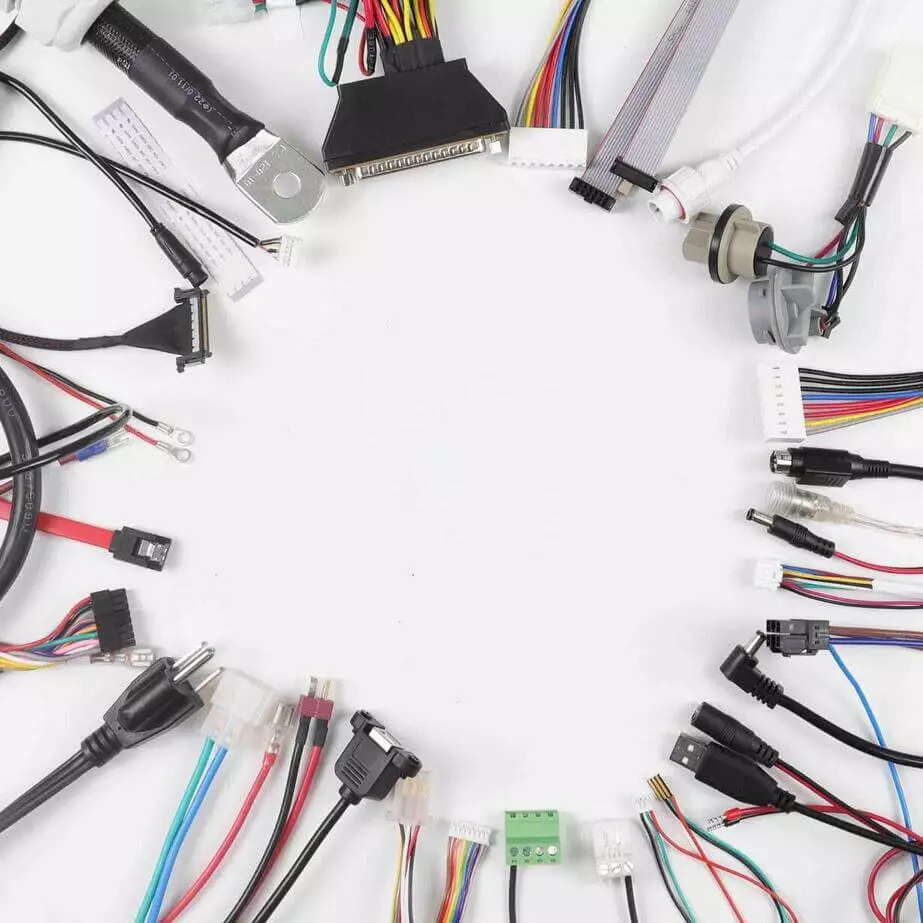

Custom Cable Assemblies

We offer a wide range of customized cable assemblies based on customers’ electrical requirements, space constraints and usage environments. These assemblies usually consist of cable + connector + jacket/marking/encapsulation structure, and are suitable for a variety of scenarios such as power transmission, signal control, and data communication.

✔ Support multi-core/multi-conductor specifications

✔ Selectable shield, jacket material, jacket color

✔ Various connector docking solutions (e.g. JST, Molex, USB, D-Sub, etc.)

✔ Support one end/both ends connector, or open wire tail processing

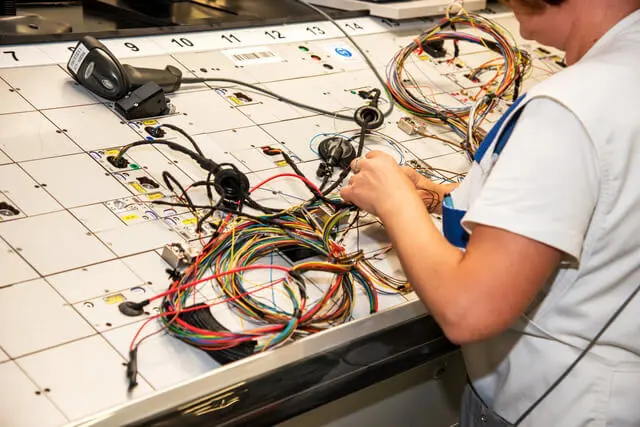

Custom Wire Harnesses

Wiring harness is a complete connection system in which multiple wires, connectors and accessories are combined together.Linkwings provides well-structured, clear wiring, safe and reliable wiring harness solutions for complex systems such as machinery control, vehicle power distribution, equipment networking and so on.

✔ Various structures such as single wire, branch wire, parallel wire, split wire, etc.

✔ Support bellows, snakeskin mesh, heat shrink tubing, numbered labels and other wrapping methods

✔ Multi-brand connector interconnection: such as TE → AMP / Molex → Hirose, etc.

✔ All wiring harnesses are tested for conductivity, voltage resistance and insulation.

Custom Overmolded Connectors

Wiring harness is a complete connection system in which multiple wires, connectors and accessories are combined together.Linkwings provides well-structured, clear wiring, safe and reliable wiring harness solutions for complex systems such as machinery control, vehicle power distribution, equipment networking and so on.

✔ Various structures such as single wire, branch wire, parallel wire, split wire, etc.

✔ Support bellows, snakeskin mesh, heat shrink tubing, numbered labels and other wrapping methods

✔ Multi-brand connector interconnection: such as TE → AMP / Molex → Hirose, etc.

✔ All wiring harnesses are tested for conductivity, voltage resistance and insulation.

Custom Multi-conductor Cables Solutions

Wiring harness is a complete connection system in which multiple wires, connectors and accessories are combined together.Linkwings provides well-structured, clear wiring, safe and reliable wiring harness solutions for complex systems such as machinery control, vehicle power distribution, equipment networking and so on.

✔ Various structures such as single wire, branch wire, parallel wire, split wire, etc.

✔ Support bellows, snakeskin mesh, heat shrink tubing, numbered labels and other wrapping methods

✔ Multi-brand connector interconnection: such as TE → AMP / Molex → Hirose, etc.

✔ All wiring harnesses are tested for conductivity, voltage resistance and insulation.

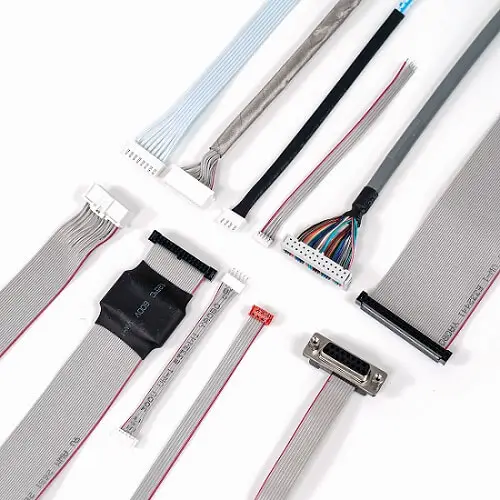

Custom Flat Ribbon Cable Assemblies Solutions

Wiring harness is a complete connection system in which multiple wires, connectors and accessories are combined together.Linkwings provides well-structured, clear wiring, safe and reliable wiring harness solutions for complex systems such as machinery control, vehicle power distribution, equipment networking and so on.

✔ Various structures such as single wire, branch wire, parallel wire, split wire, etc.

✔ Support bellows, snakeskin mesh, heat shrink tubing, numbered labels and other wrapping methods

✔ Multi-brand connector interconnection: such as TE → AMP / Molex → Hirose, etc.

✔ All wiring harnesses are tested for conductivity, voltage resistance and insulation.

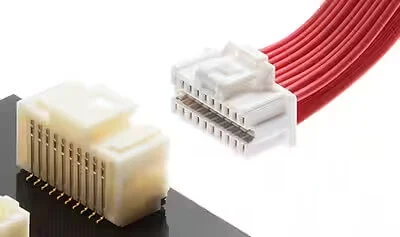

Custom Connector-to-board / Connector-to-connector Harnesses Solutions

Wiring harness is a complete connection system in which multiple wires, connectors and accessories are combined together.Linkwings provides well-structured, clear wiring, safe and reliable wiring harness solutions for complex systems such as machinery control, vehicle power distribution, equipment networking and so on.

✔ Various structures such as single wire, branch wire, parallel wire, split wire, etc.

✔ Support bellows, snakeskin mesh, heat shrink tubing, numbered labels and other wrapping methods

✔ Multi-brand connector interconnection: such as TE → AMP / Molex → Hirose, etc.

✔ All wiring harnesses are tested for conductivity, voltage resistance and insulation.

Customization Capabilities Table

| Category | Customizable Options | Description & Examples |

|---|---|---|

| Cable Type | Multi-core, Coaxial, Flat Ribbon, Shielded, Flexible | Suitable for power, signal, data, and communication applications |

| Conductor Structure | Single-stranded / Stranded, Tinned / Bare / Silver-plated Copper | Chosen based on electrical performance and corrosion resistance |

| Number of Cores | 2 to 30+ cores | Mixed signal, power, or ground lines within one assembly |

| Wire Gauge | AWG28 to AWG8 or customized | Supports both low current signal and high power applications |

| Connector Type | Molex, JST, TE, Hirose, Deutsch, USB, etc. | OEM or equivalent alternatives; available in multiple pin counts and locking styles |

| Termination Method | Soldering, Crimping, IDC, Piercing, Screw terminals | Chosen for specific reliability, environment, or assembly method |

| Connector Overmold | Injection molding, Heat shrink, Sealed boot | IP67/IP68-rated sealing with strain relief |

| Sheath Material | PVC, TPU, PUR, Silicone, PTFE | Selected for oil resistance, flexibility, abrasion, heat, flame retardance |

| Sheath Color | Black, Gray, White, Red, Yellow, Green, Blue, Transparent | Custom brand colors or multi-color identification |

| Bundling Options | Corrugated tube, Braided sleeve, Zip ties, Tape, Heat shrink | Enhances protection, appearance, and cable management |

| Shielding Options | Braided, Foil, Dual-layer shielding | EMI/RFI protection for industrial or data environments |

| Terminal Finishing | Gold-plated, Silver-plated, Tin-plated | Ensures stable conductivity and reliable connections |

| Harness Configuration | Split, Y-branch, T-branch, Loop, Dual-ended | Designed for efficient device layout and multi-point connection |

| Cable Length | 0.2m to 50m+ | Accurate to centimeter scale; labeled per layout or schematic |

| Identification | Labels, Heat shrink printing, Laser marking | Custom pin labels, logo printing, serial numbering |

| Technical Docs | 2D Drawings, Wiring Diagrams, BOM, 3D Models (STEP) | Complete engineering support for R&D, production, and QA teams |

| Special Requirements | Flame-retardant, Waterproof, Explosion-proof, UL / RoHS compliant | For high-spec industries: medical, military, railway, etc. |

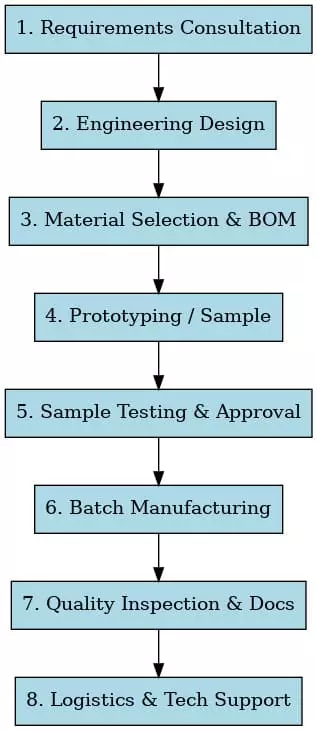

Custom Cable and Wire Harnesses Process

We provide full-process customized service support . From preliminary design, sample trial production to volume delivery, we ensure that every project is efficient, reliable and controllable.

Quality Assurance for Custom Cable and Wire Harnesses

High standard, whole process, traceable quality assurance system

We put quality control into every step of production. From the selection of raw materials to the shipment of finished products, we follow international standards and combine them with the special requirements of our customers’ industries. We pride ourselves on creating stable and reliable customized cable and wire harness solutions for our customers.

- Strictly in accordance with IPC/WHMA-A-620 standard production

- Comprehensive testing: conduction, voltage withstand, insulation, resistance, electrical performance

- Comply with ISO 9001, IATF 16949, UL, RoHS, REACH and other certificates.

- 100% factory tested + traceable batch management system

We always put “Quality is the lifeline” in every aspect of our customized cables and wire harnesses. Not only do we make sure that our products meet the standards, but we also make sure that our customers are assured of peace of mind and satisfaction with every delivery.

Use Cases or Success Stories

Surgical Robot 'Micrometer Level Nerve'

Pain Spot: 0.1mm displacement to signal interruption, disinfectant corrosion, electromagnetic interference image.

Product Portfolio:

- Pin header (LY-PH/Pro): Floating ±0.8mm vibration-resistant structure

- Gray ribbon cable (LY-RB/GM): Triple shielding (crosstalk <-70dB)

- Automotive Wire Harness (LY-AW/Hyper): Ceramicized silicone jacket (alcohol immersion resistant)

Value: United Imaging Surgical Robot: 90% Reduction in Image Noise | 10X Increase in Connector Lifespan

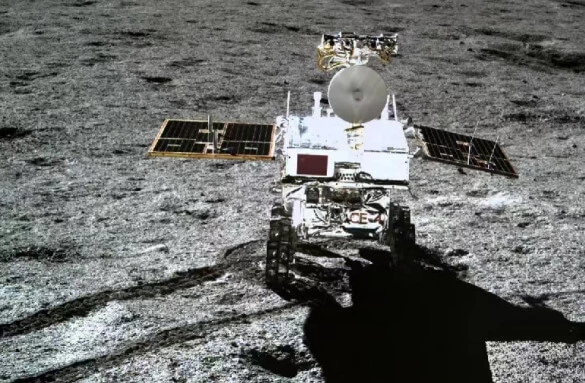

Space Exploration 'Interstellar Messenger'

Pain Spot: 180°C cold welding, cosmic ray interference, emission overweight limitation

Product Portfolio:

- Pin header (LY-PH/Pro): Golden germanium alloy contacts (resistant to cold welding)

- Automotive Wire Harness (LY-RB/GM): Carbon nanotube wires (60% weight reduction)

- Waterproof Connector (LY-WP/Shield): 1000kGy anti-irradiation shielding

Value: Chang’e 7 Lunar Rover: 53kg Weight Reduction | 0 Packet Loss in Data Transmission

25 Year Guardian of Photovoltaic Power Plants

Pain Spot: 25 years UV embrittlement, lightning strikes burn equipment, sand and dust erosion of joints

Product Portfolio:

- Grounding wire (LY-E/GD): graphene anti-corrosion layer (salt spray 3000h)

- Braided Nylon Extension Cord (LY-EC/BN): nano-diamond coating (hardness 2000HV)

- Waterproof Connector (LY-WP/Shield): IP68 + active water seepage alarm

Value: Qinghai Gobi Power Station: cable life 1 to 35 years | lightning loss ↓ ¥ 2.3 million / year

The 'Never - Ending Pulse' of Smart Factories

Pain Spot: Insufficient drag chain bending life, poor contact due to dust, loss of downtime for wire replacement

Product Portfolio:

- Braided Nylon Extension Cord (LY-EC/BN) : 5 million times bending life

- DB Solderless Header(LY-DB9/SQ) : 3 seconds quick plugging and unplugging

- Pin header (LY-PH/Pro) : IP6K9K dustproof sealing

Value: Bosch Plant: Line failure ↓98%|Mold change efficiency ↑70%.

New Energy Supercharging Station 'All-Around Guardian'

Pain Spot: 1500V high-voltage arcing risk, rainstorm short circuit, 100,000 times plugging and unplugging life is not enough

Product Portfolio:

- Waterproof connector (LY-WP/Shield): IP69K protection + 3500V arc extinguishing technology

- Automotive Wiring Harness (LY-AW/Hyper): self-healing insulation + titanium alloy armor

- Grounding wire (LY-E/GD): transient current drain 20kA/μs

Value: Super charging station evidence: failure rate ↓ 99% | single pile annual operation and maintenance costs ↓ ¥ 820,000

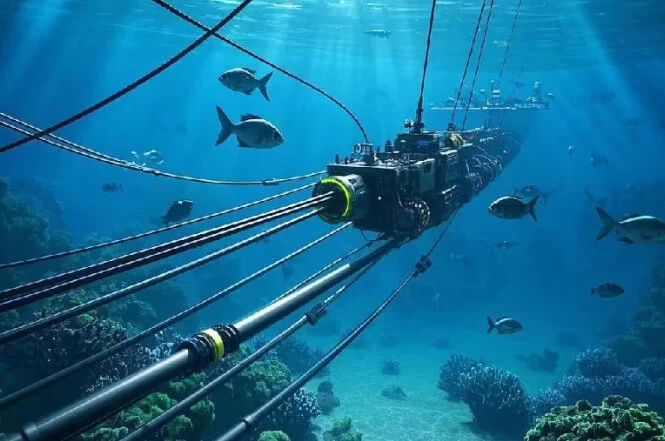

Deep Sea Robot 'Lifeline'

Pain Spot: 110MPa water pressure seal failure, sea cable entanglement breakage, long distance signal attenuation

Product Portfolio:

- Waterproof Connector (LY-WP/Shield): Titanium alloy shell (Mariana Trench Proven)

- Braided Nylon Extension Cord (LY-EC/BN): tensile strength 300kg + 200% self-healing extension

- DB to Aviation Plug: Hydraulic locking mechanism, resistant to 15G vibration

Value: CAS “Striker” application: 10,927 meters dive with zero failure, 140% of the operating time