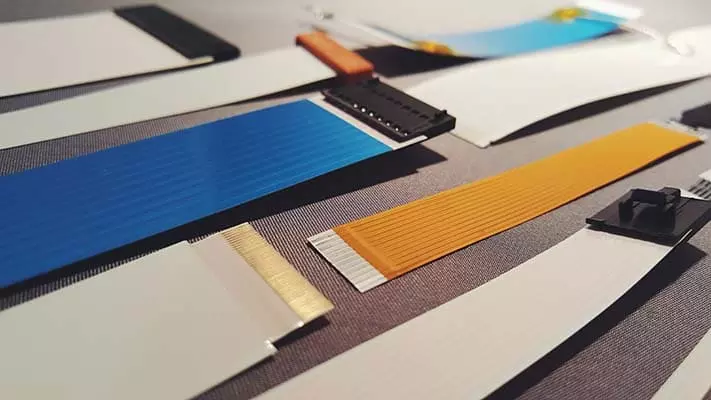

Custom Flat Cable Manufacturer in China

Custom Flat Cables Designed for Flexibility, Efficiency, and Precision

Linkwings is a reliable Custom Flat Cable Manufacturer. We provide one-stop service from structure customisation, material selection, rapid prototyping to mass production, which is widely used in industrial automation, communication electronics, medical equipment, precision instruments and other fields.

What is Flat Cable?

Flat Cable is a cable product consisting of multiple conductors arranged in parallel and covered by a uniform insulation layer to form a ribbon structure. Compared to conventional round cables, flat cables have a smaller thickness, more flexible bending performance and a neater wiring path. It is therefore particularly suitable for applications with compact spaces, dense wiring or where frequent bending is required. The basic structure of flat wire is as follows:

- Conductor: generally tinned copper or bare copper, can be single or multi-stranded stranded wire

- Arrangement: core wires are arranged in parallel according to a fixed spacing, usually in a single row, can also be customized double or multiple rows side by side

- Insulation layer: common materials include PVC, TPE, FEP, PE, silicone, etc., with flame retardant, flexible or high temperature resistant characteristics.

- Optional functional structure: aluminum foil shielding layer, braided shielding layer, reinforcement layer or heat-shrinkable tubing can be added.

Custom Flat Cable Capabilities

As a professional flat cable manufacturer, Linkwings provides one-stop customization service from cable construction design, material selection, terminal matching, functional processing to testing and delivery. Whether for signal transmission, power supply or flexible drag chain applications, we can customize high-performance, mass-producible flat cable solutions based on customer drawings, samples or requirements descriptions.

| Category | Customizable Range |

|---|---|

| Conductor Count | 2 to 50 cores; supports single-row, dual-row, and multi-row flat layouts |

| Wire Gauge (AWG) | AWG 28 to AWG 16, selected based on current load and bend radius requirements |

| Conductor Type | Tinned copper, bare copper, solid or stranded wires |

| Core Arrangement | Single-row parallel, dual-row, staggered, layered layouts |

| Insulation Material | PVC, PE, TPE, FEP, silicone, PTFE; optional flame-retardant, high-temp, or flexible grade |

| Shielding Options | None / Aluminum foil / Braided / Double shielding combination |

| Outer Jacket | Flat jacket, open split jacket, branched jacket, optional heat shrink or mesh tubing |

| Special Features | Waterproof, oil-resistant, UV-resistant, acid/alkali-resistant, flame-retardant, drag chain flexible (>5 million cycles) |

| Termination Methods | Single- or double-end crimping, IDC piercing, soldering, overmolding, connector mating |

| Additional Processing | Stripping, tubing, labeling, laser marking, cable bundling, positioning with jigs |

| Length Range | From 30mm up to 10m+; cutting precision tolerance within ±2mm |

| Industry-Specific Customization | Solutions adapted for medical, industrial automation, telecom, automotive, home appliance, military/rail sectors |

In addition to this, we offer value-added services. Including the provision of supporting electrical test, tensile test, bending test report; provide label number, BOM file and packaging customization. And can support the signing of NDA, drawing confidentiality and exclusive project management.

Custom Flat cables types from linkwings

Linkwings offers a wide range of Flat Cable products to suit different electrical connection needs, mechanical movement scenarios and industry specifications. Whether it’s a thin, flexible signal cable or a powered flat cable for industrial drag chains, we can customize it to meet your needs and deliver it quickly.

- Structural features: copper foil conductor + polyester (PET) insulation film, ultra-thin structure (thickness of about 0.12 ~ 0.35mm)

- Termination: Commonly used plug-and-play connectors, ZIF/LIF mounts, soldering.

- Advantage: Thin, light, flexible, suitable for precision connection in narrow space.

- Structural features: multiple parallel copper wires with uniform insulation, strip cross-section

- Optional structure: 2 cores to more than 50 cores, single row/double row/spliced arrangement

- Advantages: neat wiring, easy to manage and install, support for cutting and splicing.

- Structural features: aluminum foil or braided shielding layer is added on top of the flat wire to effectively prevent electromagnetic interference (EMI).

- Shielding method: single layer aluminum foil / braid / double layer composite

- Advantage: Stable signal transmission, strong anti-interference performance, suitable for high-precision electronic equipment.

- Structural characteristics: thick diameter conductor + highly flexible insulating material, support for continuous bending and trailing use.

- Performance requirements: oil resistance, abrasion resistance, high and low temperature resistance, tensile strength, flame retardant, life expectancy up to 5 million drag chain cycles or more.

- Advantage: Excellent fatigue resistance, suitable for high frequency bending industrial occasions.

- Structural features: splicing of multiple functional lines into a single cable, or the use of upper and lower layers of structural distribution

- Applicable scenarios: space-constrained equipment wiring, electrical + signal composite transmission requirements

- Advantage: high degree of functional integration, customizable structure, flexible wiring

why use flat cables?

The use of flat cables enables high-density, flexible, low-interference and high-efficiency cabling solutions in limited spaces. This is ideal for medical devices, industrial automation, communication systems, automotive electronics, consumer electronics and other industries that demand high connection reliability and space utilisation. Choosing flat cables is an important step in the optimisation of connections for modern smart devices.

- Space saving, neat wiring

- Good flexibility and bending resistance

- Signal consistency and anti-interference ability

- Easy processing and termination

- Multi-functional integration, improve system reliability

Industries We Serve

Linkwings’ customized flat cables are used in a wide range of technology-intensive industries. They cover a wide range of connectivity needs, from automation equipment to medical electronics, from precision communications to new energy transportation. Not only do we understand the specific requirements of the industry for flat cable performance, but we also have the engineering support to provide customized structures and process optimization based on project scenarios.

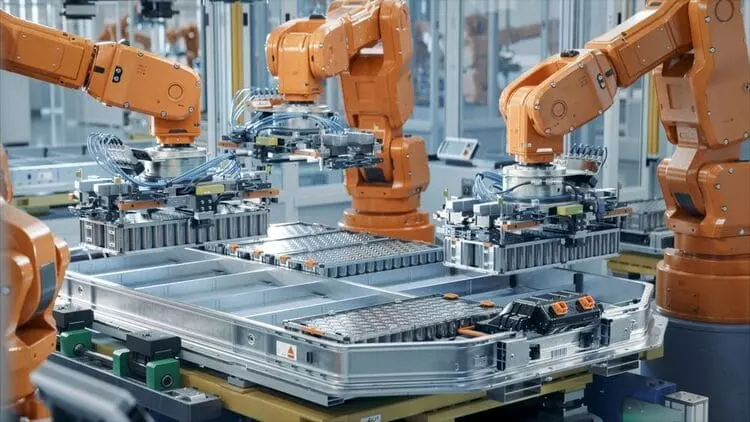

Power flat cables, shielded signal flat cables, and multi-core control cables are often used in Industrial Automation applications. Typical applications include PLC control systems, robotic arms, multi-axis slide tables, linear modules, and photoelectric sensor connections.

Linkwings flat cables have a dynamic bending life of ≥5 million cycles.

Medical devices have high requirements for flat cables in terms of biocompatibility, softness and bendability, high temperature resistance and high insulation. And linkwings’ FFC flexible cables, silicone insulated flat cables, and multi-functional splicing structure can meet their needs. Typical applications include ultrasound equipment, monitors, blood analysers, in-vitro diagnostic systems, and intelligent operating tables.

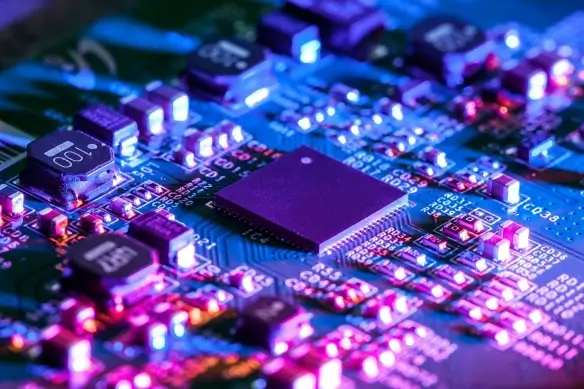

5G small base station, camera module, car central control screen, drone signal line, laptop cable and other applications will use flat cables. because flat cables have good signal integrity, low crosstalk, high density connection, high space utilisation.

Applicable products: FFC cable, shielded flat signal cable, custom terminal connector assembly cable.

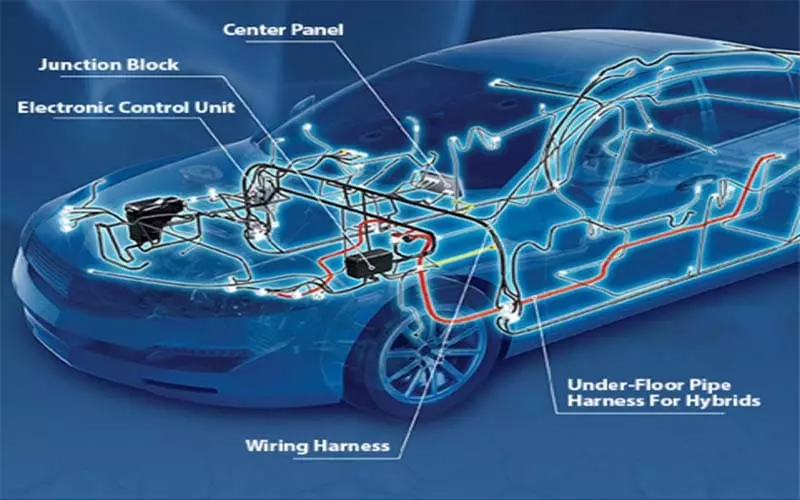

Automotive’s requirements for flat cable are high and low temperature resistance, strong vibration reliability, fire retardant, waterproof, anti-dull plug design. Double-row flat cable, injection-moulded terminated flat cable, fatigue-resistant and vibration-resistant structural cable and other products can meet its needs. Therefore, they are commonly used in instrumentation centre control module, reversing camera, radar sensor system, automatic door track wiring, lift control system.

Typical applications: PV module crossties, energy storage battery management BMS connections, power module signal communication

Key Requirements: High insulation and pressure resistance, UV resistance, waterproof and corrosion resistance, system level EMC compatibility.

Applicable products: high-voltage flat power cables, shielded power cables, string-type flat converging cables

Typical applications: analytical instruments, measurement equipment, robot modules, intelligent terminals, electronic control panels

Key Requirements: Compact structure, easy installation, bendable wiring, no signal distortion.

Applicable products: Multi-layer composite flat cable, small-size FFC cable, precise marking+anti-misplaced cable.

Manufacturing & Testing Strength

As a professional flat cable manufacturer, Linkwings has a complete set of advanced production equipment and strict quality control system from raw material processing to finished product testing. It ensures that every flat cable that leaves the factory meets the industry or customer standards in terms of structural accuracy, electrical performance, and flexibility life.

Linkwings has advanced flat cable processing lines. It supports automatic wire cutting, precision stripping, double-end crimping, IDC piercing, welding, heat-shrinking, injection moulding and other processing techniques. Therefore, Linkwings is able to flexibly respond to the customised demands of multi-core, multi-structure and multi-interface, and achieve high precision and high efficiency production delivery.

We are equipped with perfect electrical and structural testing equipment. Including conductivity tester, high-voltage insulation tester, tensile tester, dynamic bending test machine and so on. All products are 100% inspected before leaving the factory, and we can provide EMI, flame retardant, wear-resistant and other special test reports if necessary. We ensure that every flat cable meets international standards and customer requirements in terms of performance, safety and life.

What types of flat cables do you offer? Can you customize the structure?

We can produce FFC flexible cable, multi-core flat cable, shielded flat cable, drag chain flat cable, etc.. We also support customised core number, gauge, layout, sheath material, shielding structure, etc.

How do I start a custom flat cable project? What should I provide?

You only need to provide preliminary drawings, samples, wire gauge, number of cores, length, terminal type or use scenarios. Our engineers will assist you to complete the structural design and selection confirmation.

Do you offer termination services such as crimping, IDC, soldering or injection moulding?

Yes, we can provide complete assembly services such as terminal crimping, IDC piercing, soldering treatment, injection moulding overmoulding, adding heat-shrink tubing, and labelling upon request.