Custom Automotive Wiring Harnesses

—— Tailored Solutions for Your Vehicle

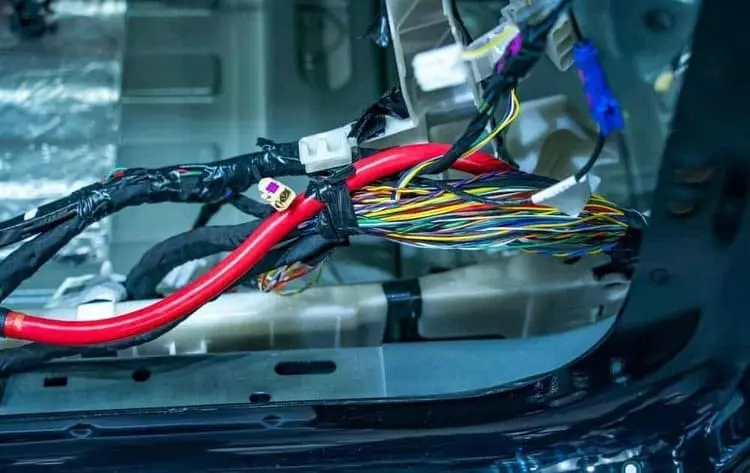

Discover how custom automotive wiring harnesses can enhance the performance, safety, and reliability of your vehicle. Whether you’re upgrading a classic car or building a specialty vehicle from scratch, tailored harness solutions ensure seamless integration and long-term durability.

Why Choose Custom automotive Wiring Harnesses

Custom Automotive Wiring Harness is becoming the preferred choice of an increasing number of professionals and enthusiasts in the manufacturing or modification of modern automobiles and specialty vehicles. Custom wiring harnesses offer multiple advantages over generic harnesses or hand wiring. It can significantly improve the reliability, safety and electrical performance of the entire vehicle.

perfect fit for unique vehicle designs

Custom automotive wiring harnesses are tailored to the specific vehicle model, electrical system requirements and equipment configuration. This means that every wire length, connector type, and routing is precisely adapted to your vehicle’s architecture, avoiding redundancies, incompatible interfaces, and other issues. Especially suitable for the following scenarios:

- Conversion or retro car projects

- Electric vehicle (EV) conversions

- Customized vehicles such as race cars and off-road vehicles

improved electrical system efficiency

Custom wiring harnesses can help optimize electrical system layouts and reduce voltage loss and signal interference. The use of higher quality wires (e.g. high purity or tinned copper), high temperature resistant insulation (e.g. XLPE, Teflon) can:

- Improve conductive efficiency

- Reduce energy waste

- Extend wire harness life

enhanced safety and reduced fire risks

General-purpose wiring harnesses are prone to short-circuiting, deterioration, or loosening when dealing with high current, vibration, or high temperature environments. Customized car wiring harnesses, on the other hand, use industrial-grade connectors, protective sleeving (such as braided wire mesh and heat-shrink tubing) and reasonable grounding strategies to effectively reduce the following risks:

- Fire caused by overloaded circuits

- System failure due to signal loss

- Intermittent problems caused by loose plugs

easier maintenance and troubleshooting

Custom automotive wiring harnesses come with clear wiring harness markings (e.g. heat shrink labels, laser markings), documented electrical drawings and modular designs. As a result, post-maintenance of custom automotive wiring harnesses is very easy for automakers:

- Quickly locate problem wiring harnesses

- Units can be replaced or upgraded without disassembling the entire vehicle

- Easy integration of new electronic devices (e.g. GPS, reversing radar, controllers, etc.)

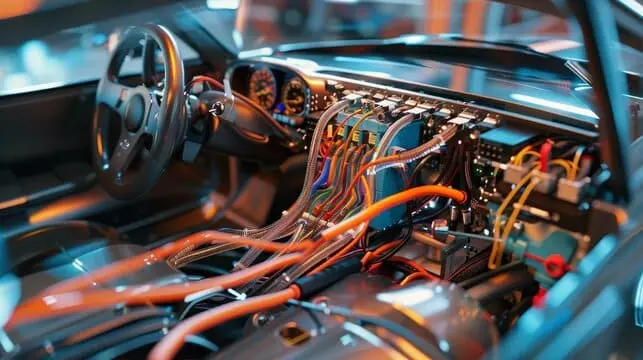

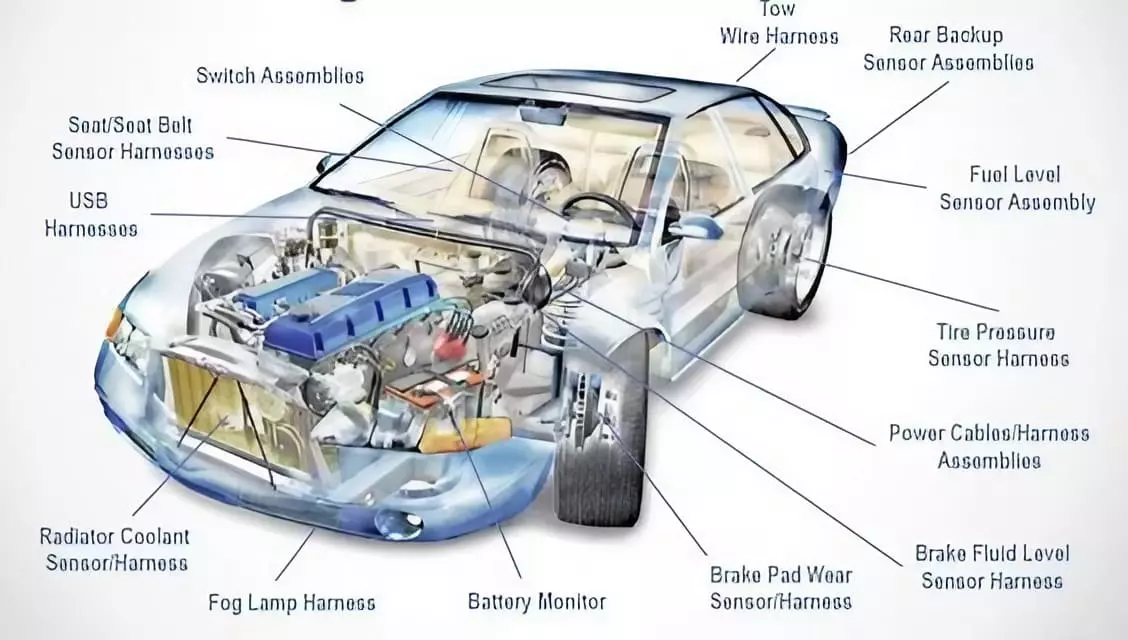

support for advanced electronics (ECUs,CAN bus,Sensors)

Modern vehicles are increasingly utilizing intelligent technologies such as CAN buses, sensor networks, and remote diagnostic systems (OBD). There is no way that a standard wiring harness can meet the wiring requirements for these functions. Customized automotive wiring harnesses provide a stable data transmission environment and dedicated interface support for these systems.

Demonstrate professionalism and brand image

For automotive tuners, OEMs, and racing teams, a neat and professional wiring harness not only enhances the performance of the car, but also reflects the brand’s professionalism in electrical systems. This is important when it comes to commercial projects or customer deliveries.Custom automotive wire harnesses are the best solution when facing complex electrical requirements.

- Higher system integration

- More reliable electrical performance

- Greater controllability and expandability

Custom Car Wiring Harness Applications

As vehicle electrical systems become more complex and diverse, Custom Automotive Wiring Harnesses are being used in a wide range of segments. Whether it’s for performance upgrades, system integration or the development of special-purpose vehicles, custom wiring harnesses play a vital role.

Classic cars / Hot rods

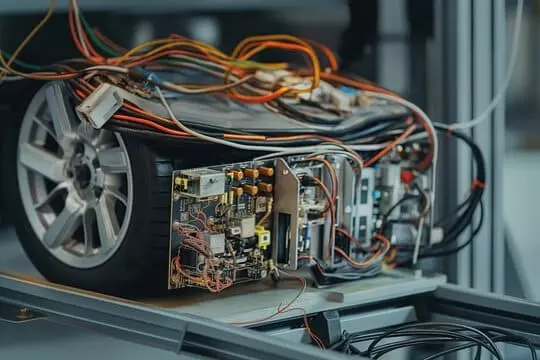

EV conversions

Off-road vehicles / UTVs / ATVs

Heavy-duty trucks

Motorsport / Race cars

Specialty or military vehicles

Custom Automotive Wiring Harnesses Process

Customizing a high-quality automotive wiring harness is not just a matter of cutting a few wires and plugging them in. It is a specialized process that requires engineering design, material selection, manufacturing process and testing and validation. Below is our standardized wiring harness customization process:

Consultation & Requirements Gathering

We talk in depth with our customers to understand the vehicle type, application, electrical system requirements, budget and lead time, and gather the necessary information. Example:

- Vehicle model and year (or CAD drawings)

- Number and type of connected devices required (ECU, lights, sensors, etc.)

- Supply system voltage (e.g. 12V, 24V, high voltage EV systems)

- Alignment environment (engine compartment, chassis, interior, etc.)

🔍 Purpose: To ensure that we provide you with a “customized” and not a “template”.

Design & Schematic Development

| Category | Description |

|---|---|

| Conductor Material | High-purity copper, tinned copper, aluminum alloy |

| Insulation Type | PVC, XLPE, Teflon (PTFE), silicone rubber |

| Sheathing Options | Heat shrink tubing, braided sleeving, corrugated (convoluted) loom |

| Connectors | Waterproof (IP67), high-temperature, quick-connect types |

| Certifications & Standards | RoHS, UL, ISO/TS16949, SAE J1128, CE |

Material Selection & Specification

We talk in depth with our customers to understand the vehicle type, application, electrical system requirements, budget and lead time, and gather the necessary information. Example:

- Vehicle model and year (or CAD drawings)

- Number and type of connected devices required (ECU, lights, sensors, etc.)

- Supply system voltage (e.g. 12V, 24V, high voltage EV systems)

- Alignment environment (engine compartment, chassis, interior, etc.)

🔍 Purpose: To ensure that we provide you with a “customized” and not a “template”.

Prototyping & Testing

After the design is confirmed, we make samples or the first batch of prototype lines and conduct a series of rigorous tests:

- continuity check

- Insulation resistance and voltage test

- Plug verification and compatibility test

- Simulated installation test (to ensure correct interface position)

🔌 Additional services: We can provide photos or short videos of the samples for remote acceptance.

Final Production & Delivery

After the samples are confirmed to be correct, we enter the formal production stage:

- Use of automatic crimping machine, terminal crimping force control system and other high-precision equipment

- 100% factory function test (with conditions with two-dimensional code traceability system)

- Packaging against moisture, supporting documents (drawings, cable numbers, installation instructions)

🚚 Shipping method: optional local warehouse pickup, international express delivery, bulk consignment transportation, etc.

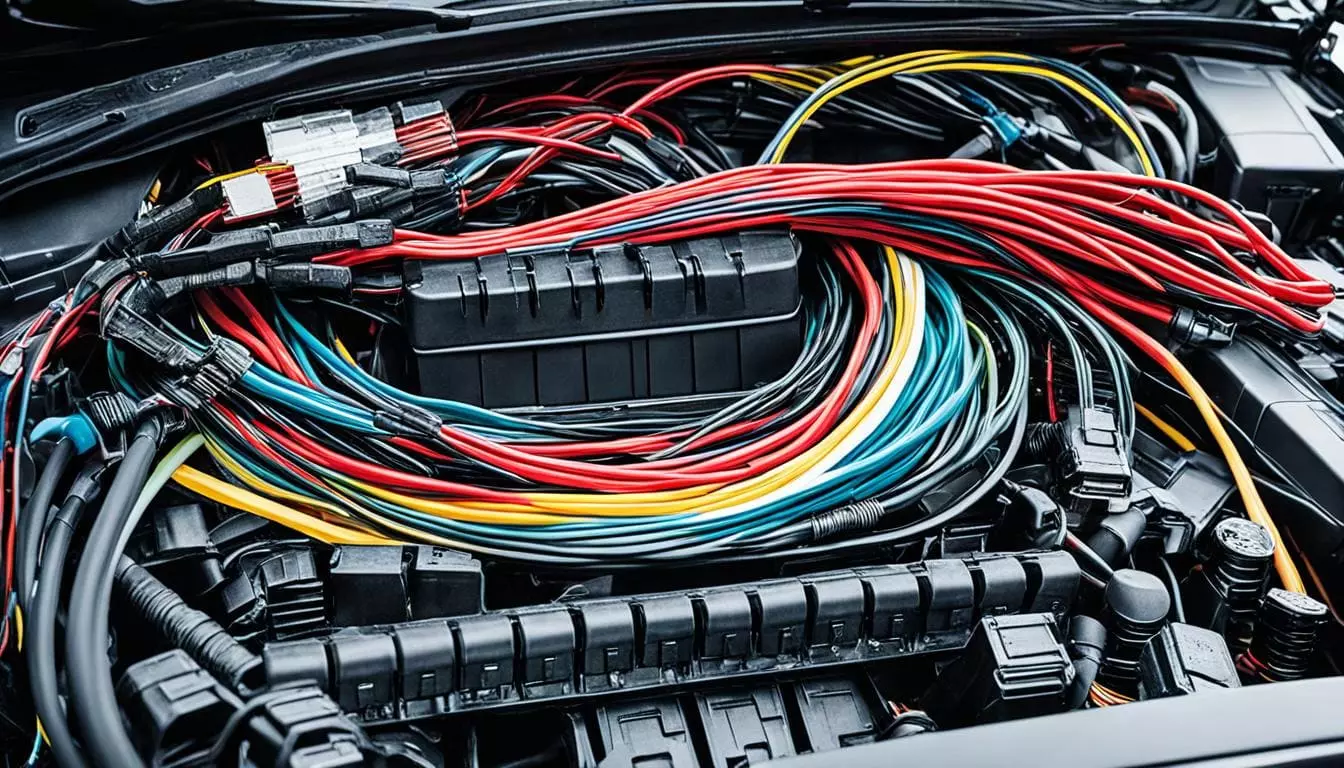

Specs & Materials Used for Custom car wiring harnesses

Made to OEM Standards

The quality and performance of customized automotive wiring harnesses depend more than 80% on the core materials used and the control of technical parameters. Different application scenarios (e.g. racing cars, engineering vehicles, electric vehicles) have different technical requirements for the electrical characteristics, physical strength, and environmental adaptability of the wiring harness.

Conductor Material of custom car wiring harnesses

- High Purity Oxygen Free Copper (OFC): Excellent conductivity, commonly used in mains power cables.

- Tinned Copper : Increase oxidation resistance and corrosion resistance, suitable for humid or high salt environment.

- Aluminum Alloy: suitable for occasions with high lightweight requirements but not much current.

💡 When choosing a conductor, you need to balance the conductivity, flexibility, cost and weight.

custom Insulation Material for car wiring harnesses

- PVC: low cost, suitable for non-extreme environments Passenger car interiors

- XLPE: High temperature (up to 125°C), abrasion-resistant Engine compartment, electric vehicle

- Teflon (PTFE): over 200°C, excellent electrical properties Motorsports, aerospace, military

- Silicone Rubber: soft, high and low temperature resistance (-60°C~200°C) RV, medical, harsh environments

🧪 All insulation materials are RoHS compliant to avoid the release of hazardous substances.

custom Sheathing & Physical Protection for car wiring harnesses

- Heat Shrink Tubing (Heat Shrink Tubing): waterproof encapsulation, enhance structural stability.

- Braided Sleeving: Enhances mechanical strength and aesthetics, and facilitates wire management.

- Corrugated Loom: anti-abrasion and anti-pressure, suitable for chassis and door panel wiring.

- Fire-Resistant Cloth Tape Wrap (Fleece Tape / Fire-Resistant Tape): for NVH control (noise reduction), fire prevention, anti-vibration.

🚗 Specialty vehicles and off-road vehicles recommend a double sheathing solution to increase the level of protection to IP67 or IP69K.

custom Connectors & Terminals for car wiring harnesses

We offer a wide range of automotive grade connectors to ensure good contact, fast plugging and weatherproofing:

- Types include: waterproof connectors, multi-pin connectors, locking type, quick release type, etc.

- Protection level: up to IP67/IP69K, suitable for rainstorms, car washes or extreme working conditions.

⚙️ All terminals are crimped to meet SAE and IPC/WHMA-A-620 standards.

custom Wire Gauge & Color Coding for car wiring harnesses

- Common specifications: 0.22mm² ~ 25mm² (AWG24 ~ AWG3), can support small signal lines to the main power line

- Gauge selection basis: current carrying capacity, voltage level, wire length, electrical impedance, etc.

- Color coding: support for customer-specific standards (e.g. DIN, SAE, OEM color coding)

🎯 Optional heat-shrink marking with number, printed wire, laser marking, etc. for easy maintenance.

Case Studies or testimonials

A startup company was converting a traditional diesel pickup truck to a pure electric drive platform and needed a safe, reliable battery and electronic control wiring harness that complied with high-voltage system specifications.

✅ Solution:

Provide high voltage insulated wires (rated 600V or above) with double layer protection!

Match the control system interface of BMS, VCU, charging port, etc.

Produce clear schematic diagrams to support future API control interface reservation

Each cable is tested for insulation voltage and signal continuity.

📈 Achievements:

The system operates successfully at the first time of wiring, with no short-circuit/interference problems.

Vehicle commissioning time reduced by more than 30%.

The customer successfully passed the electrical certification and the product was put into the market for trial operation.

🗣️ Customer comment:

“This is not a wiring harness, it is the electrical nervous system of the whole vehicle, thank you for making it work safely and efficiently.”

A racing team was preparing to participate in the Tour de France cross-country rally, and the original wiring harness was in urgent need of upgrading due to loose connections, complicated maintenance, and high failure rate during the race.

✅ Solution:

Adopting high temperature resistant Tefzel wire + Deutsch connector

Optimized wiring harness layout, modular design for quick replacement during the race.

Add waterproof and dustproof package structure, passed IP67 test.

Provide wiring harness numbering diagram and quick replacement manual.

📈 Results:

Not a single harness failure during the race, winning the Finishers Award.

Reduced race repair time by 50% and improved strategic scheduling efficiency.

Became a long-term customer for harness customization for subsequent races

🗣️ Customer Testimonials:

“After using this harness, we don’t want to touch the original manual wires anymore. It’s so stable!”

FAQs about custom Automotive wiring harnesses

How long does the lead time for a custom automotive wiring harness take?

The production lead time for customized wiring harnesses usually varies depending on the complexity of the project. From requirement communication, drawing design to sample production, it usually takes 5-7 working days for simple projects; complex projects (e.g. with modules, BMS interfaces, CAN communication, etc.) take 10-20 working days.

If it involves high-voltage systems (such as electric vehicle power harness), multi-interface compatibility or wiring harnesses with high protection level requirements, the cycle time may be extended to more than 4 weeks. We also provide expedited service, which can be flexibly adjusted according to the project progress.

What information is required to begin customization?

To help us design the wiring harness accurately, it is recommended that you prepare the following information at the consultation stage: vehicle type, year, number and location of devices to be connected, voltage system (12V/24V/HVEV), whether waterproof/heat-resistant design is needed, etc. It would be better if you have a wiring diagram or CAD file, but if not, you can also illustrate it with hand-drawn sketches or photos.

If you are an OEM or professional tuner, we can also assist in completing the design input documents (DVP, BOM list, electrical topology diagram, etc.). Our technical team will work with you to ensure that the design is efficient, accurate, and production ready.

Is the customized automotive wiring harness available for mass production? Does it support OEM?

Of course. We have long been providing OEM wiring harness services for automotive tuning plants, equipment manufacturers, engineering machinery plants, and OEMs. We support from sample development to mass production, and work with customers to establish product coding, inventory management, customized packaging and delivery systems.

In addition, we support customers to customize exclusive connector combinations, printed logos, customer labels (e.g., logo heat-shrinkable tubing) and other personalized solutions. We can also sign Non-Disclosure Agreements (NDAs) to ensure that technical solutions and drawings are not disclosed.