Custom Trailer Wire Harness – Complete Guide & Product Selection

Custom trailer wire harness from Linkwings. Get factory price fom wire harness manufacturer.

what is trailer wire harness?

Trailer Wire Harness is a set of cable assemblies used to connect the electrical system between the towing vehicle (e.g. car, pickup truck) and the trailer. Its main function is to extend the vehicle’s lighting, power and signaling systems to the trailer end, ensuring that the trailer’s brake lights, taillights, turn signals, license plate lights, etc. work in tandem with the main vehicle to meet the requirements of road safety and traffic regulations.

A typical trailer wire harness usually includes the following parts:

- Multiple strands of color-coded wire (corresponding to different light signals)

- Plugs/sockets (e.g. 4-pin, 5-pin, 7-pin and other standard interfaces)

- Ground wire and mounting clips

- Sometimes auxiliary components such as heat shrink tubing, retaining clips, fuse holders, etc. are also included

- Translated with DeepL.com (free version)

Why are trailer wiring harnesses important?

Trailer wire harness is an essential part of every trailer. It not only affects the lighting function, but also directly relates to the driving safety and legalization on the road. Choosing a set of stable structure, standard plugs and matching interfaces is a serious task for every trailer owner, manufacturer or tuning engineer.

- The United States, the European Union, Australia and other regions have clearly stipulated that trailers must be equipped with a complete lighting and signaling system, and trailer wire harness is the core connection bridge.

- If the trailer can not synchronize the display of brake lights or turn signals, it will seriously affect the judgment of the rear vehicle, and is very likely to cause accidents such as rear-end collision.

- The wiring harnesses are usually pre-installed with plugs and wires, so users only need to connect the wires according to the color and plug them into the trailer jacks.

Types of Trailer Wire Harness & Plug Standards

Trailer wiring harnesses are not “one-size-fits-all”, but are categorized into a variety of structures and plug configurations based on the type of trailer, functional requirements, and interface standards of the towing vehicle. The most common classification is based on the number of plug pins, such as 4-pin, 5-pin, 6-pin, 7-pin and so on. These standardized interfaces not only determine the functionality supported by the harness, but also have a direct impact on its compatibility with vehicle models and legal compliance.

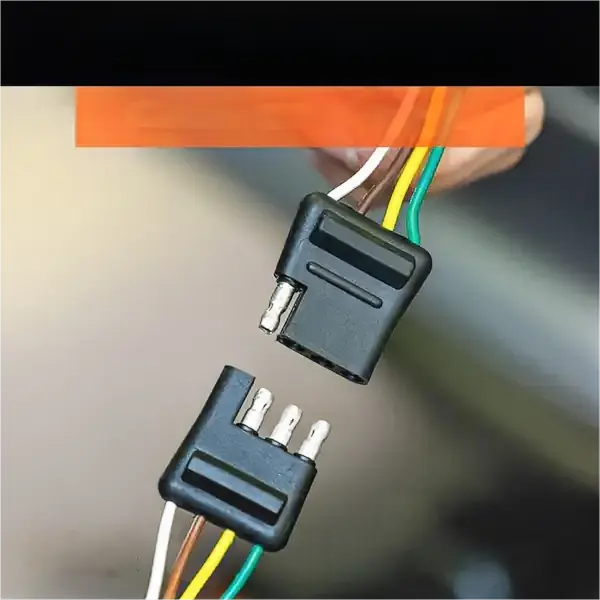

4 Pin Flat trailer wire Harness

- Common use: small trailer, simple cargo bucket, camping trailer

- Supported functions: tail lights, brake lights, left and right turn signals

- Advantages: simple structure, low cost, easy to install

- Limitations: Doesn’t support reverse lights, electromagnetic brakes, auxiliary power supply and other expanded functions.

- Typical vehicles: pickup trucks, SUVs, small cars

5 Pin Flat trailer wire Harness

- Common use: boat trailer with electromagnetic brake or release control, water sports trailer bucket

- Supported Functions: 4-pin basic function + 5th pin to control brake release or reverse lights

- Features: Suitable for scenarios where additional control signals are required

- Compatibility: Compatible with 4-pin interface, expandable upwards

6 Pin Round trailer wire Harness

- Common use: light caravan, small enclosed trailer, agricultural trailer

- Support function: tail light, brake light, turn signal, reverse light, brake signal, 12V power supply

- Structure: round metal plug, usually more robust, suitable for outdoor use

- Common accessories: brake controller, backup power access

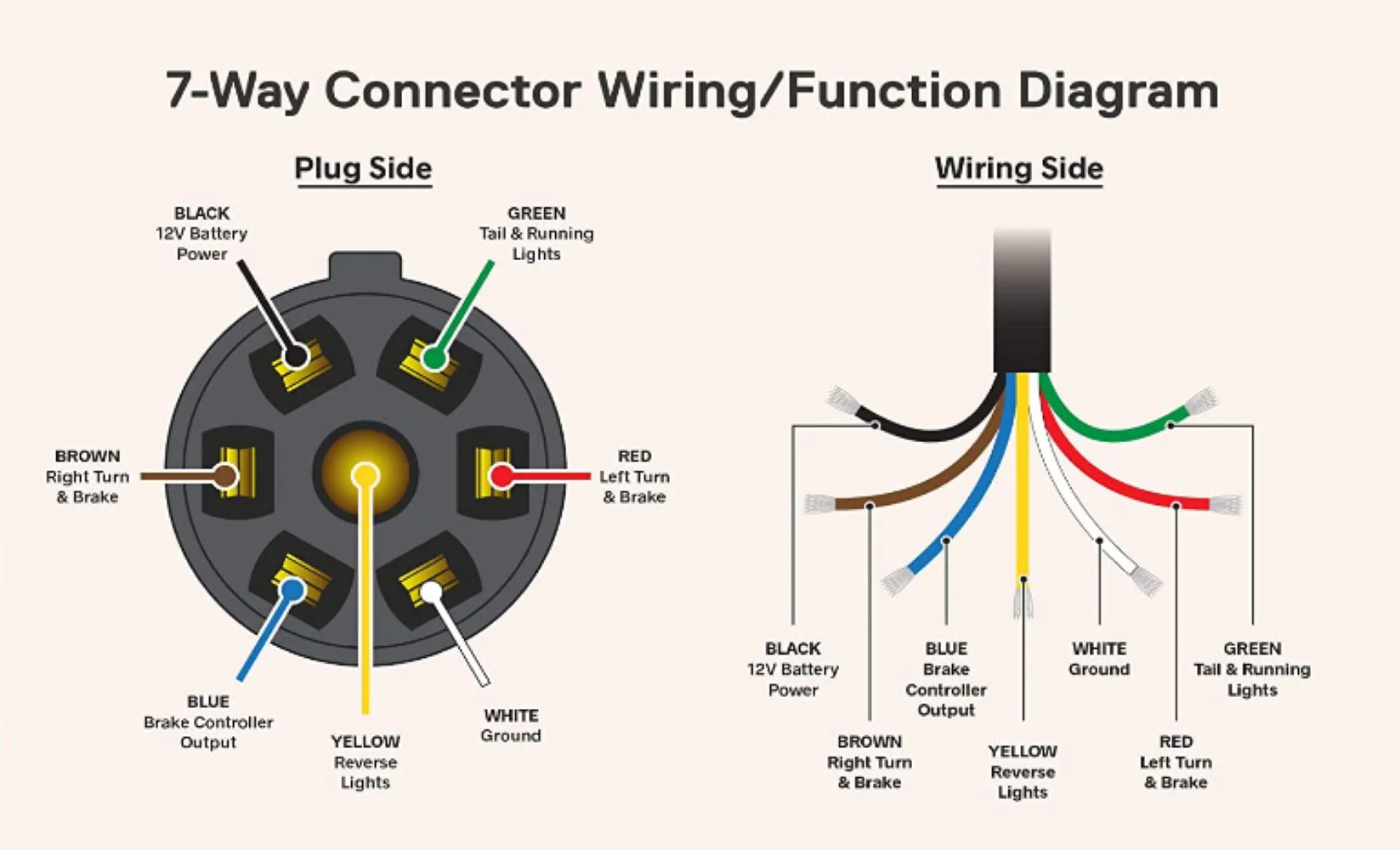

7 Pin RV Blade trailer wire Harness

- Common Uses: Large motorhomes (RV), heavy duty trailers, campers, electric brakes

- Supported Functions: Includes all light signals + brake control + reverse + power supply + grounding

- Advantage: Most versatile, suitable for high load complex electrical systems

- Standard: SAE J2863, NATM towing standard.

- U.S. mainstream interface, most U.S. tractor-trailer vehicles are equipped with this interface as standard.

7 Pin Round trailer wire Harness

- Common Uses: EU/Australia common trailer system

- Supported features: Similar structure to US 7-pin, but with different pin definitions.

- Note: US and European 7-pin interfaces are not directly interchangeable, you need to check the market standard before purchasing.

Waterproof Customm Trailer Harness (OEM/ODM)

- Support plug type: 4/5/6/7-Pin (Flat/Round) can be customized.

- Function expansion: Reverse camera interface, 12V DC power supply cable, CAN signal cable

- Protection level: IP67/IP68, suitable for long-term outdoor applications

- Customized content: plug type, wire length, color coding, labeling, packaging.

| Plug Type | Pins | Supported Functions | Typical Trailer Types |

|---|---|---|---|

| 4-Pin Flat | 4 | Tail lights, brake lights, left & right turn signals | Utility trailers, light-duty flatbeds |

| 5-Pin Flat | 5 | Above + reverse lights or electric brake release | Boat trailers, marine sports trailers |

| 6-Pin Round | 6 | Tail/brake/turn + reverse + 12V power + brake signal | Small RVs, horse trailers, farm trailers |

| 7-Pin Blade (RV) | 7 | Full lighting + brake controller + 12V power + ground | Travel trailers, enclosed cargo trailers, RVs |

| 7-Pin Round (EU) | 7 | European standard wiring (different pin definitions) | EU-compliant trailers, export markets |

How can you tell which plug to use?

- Look at what electrical features the trailer itself has: does it have reverse lights? Does it use electromagnetic brakes? Does it have a backup power supply?

- Look at the type of plug interface of the towing vehicle: you can observe whether it is 4/5/7 pins through the tail socket.

- Confirm the market standard: US vs. EU interface can not be mixed, need to pay special attention to the export program.

- Recommended way: choose the matching plug and try to pre-install the grounding wire, cable ties and waterproof package for easy installation.

Why choose our Trailer Wire Harness?

When it comes to towing safety, electrical stability and long term durability, a quality trailer wire harness is far more important than its cost. trailer wire harnesses provided by Linkwings not only comply with various regulations and industry standards, but also strive for consistency and reliability in terms of materials, design and manufacturing process. That’s why we are the long-term partner of many OEMs, trailer manufacturers and retrofit users.

100% Pure Copper Conductor - Stable and Durable

We use 100% pure copper conductor to ensure stable signal transmission and sufficient illumination. At the same time, the outer layer is made of wear-resistant and anti-aging PVC or rubber sheath, and the plug part adopts one-piece injection molding design. Therefore, it has good waterproof and dustproof performance and is suitable for all kinds of outdoor harsh environments.

100% testing before shipment

Every wire harness has to pass 100% on-off test, grounding test and plug strength test before leaving the factory. Some models also support high voltage and tensile strength testing. To ensure that every product in the hands of the customer meets the actual use requirements and safety standards.

Full range of models - strong compatibility

We provide 4-pin, 5-pin, 6-pin, 7-pin and other standard wiring harness configurations. We also support different lengths, wire diameters and plug configurations. It can be adapted to various types of vehicles and systems, such as RV, small trailer, boat trailer, etc., which ensures quick installation and plug-and-play.

Support customization - flexible matching

We provide OEM/ODM customization service for special projects or customer requirements. Including wire length, color coding, plug combination, function expansion (such as reverse camera, power cord, CAN cable, etc.). We can also add customer LOGO and customized packaging, suitable for engineering or brand cooperation needs.

Applications of trailer wiring harnesses

Trailer Wire Harness is not only suitable for regular small trailers, but is also used in a wide variety of outdoor, transportation, recreational and industrial scenarios. We offer wire harnesses that are compatible with a wide range of vehicle types, plug interfaces and environmental requirements, for a variety of uses from personal modifications to commercial projects.

- Boat Trailers

- RV & Camper Trailers

- Cargo / Utility Trailers

- Farm & Flatbed Trailers

- Aftermarket Repair / Custom Builds

Installation Diagram of trailer wire harness

| Wire Color | Function | Connection / Purpose |

|---|---|---|

| White | Ground | Attach to trailer chassis or frame |

| Brown | Tail / Marker Lights | Rear running lights on both sides |

| Yellow | Left Turn Signal + Brake Light | Driver-side turn signal and brake lamp |

| Green | Right Turn Signal + Brake Light | Passenger-side turn signal and brake |

| Blue | Electric Brakes | Controls trailer brake system |

| Red | Reverse Lights | Activates when reversing |

| Black | 12V Auxiliary Power | Charges trailer battery or powers accessories |

1. Should I choose a 4-pin, 5-pin or 7-pin trailer wiring harness?

Which type of plug to choose depends on your trailer’s functional needs and the type of tractor outlet.

- If you only need taillights, brake lights, and turn signals, 4-pin is sufficient.

- If the trailer has reverse lights or electromagnetic brakes, 5-pin is recommended.

- If you also need advanced features such as power supply, brake controller, etc., you should use a 7-pin harness.

- Also check the number of pins and connector shape of your tractor’s tail socket to ensure compatibility.

2. Is your harness waterproof? Is it suitable for outdoor use?

Yes, most of our Trailer Wire Harnesses are designed to be waterproof. This includes: injection molded plugs, heat shrink tubing protection, and IP65 or higher rated jacketing materials.

For boat trailers or long-term outdoor use, we recommend a model with a corrosion-resistant plug and rubber boot. This model ensures stable operation in rain, mud, salt spray and other environments.

3. Do I need specialized tools to install Trailer Wire Harness? Can I install it myself?

No special tools are required. Most standard wiring harnesses are plug-and-play configurations, so all you need to do is secure the main wires with cable ties, properly ground the wires, plug them into a tractor outlet, and test for functionality. Clear wiring diagrams are available for all our products. For customized configurations, installation instructions or remote technical support are also available. Users with basic hands-on skills can do the installation by themselves.

4. Do you support customized wiring harnesses? What is the minimum order quantity?

Yes, we do. We can provide OEM/ODM customization service according to your drawings, samples or functional requirements. Including wire length, color coding, plug combinations, case marking, brand labeling, etc.. For engineering samples or small batch trial production, we do not set any MOQ limit, and support sampling first, then bulk delivery.

5. Do the products comply with North American or EU regulations and standards? Do you support export?

Our products comply with SAE J2863 (U.S. standard trailer plug), RoHS, CE, REACH and other mainstream market certification requirements. We can also provide European Standard 7-Pin Round Plug Wire Harness according to customer’s requirements to meet the European/Australian market specifications. We support the provision of material description, compliance report, packing list, CO and other export documents, which are suitable for e-commerce platforms, cross-border projects, containerized shipments and other scenarios.