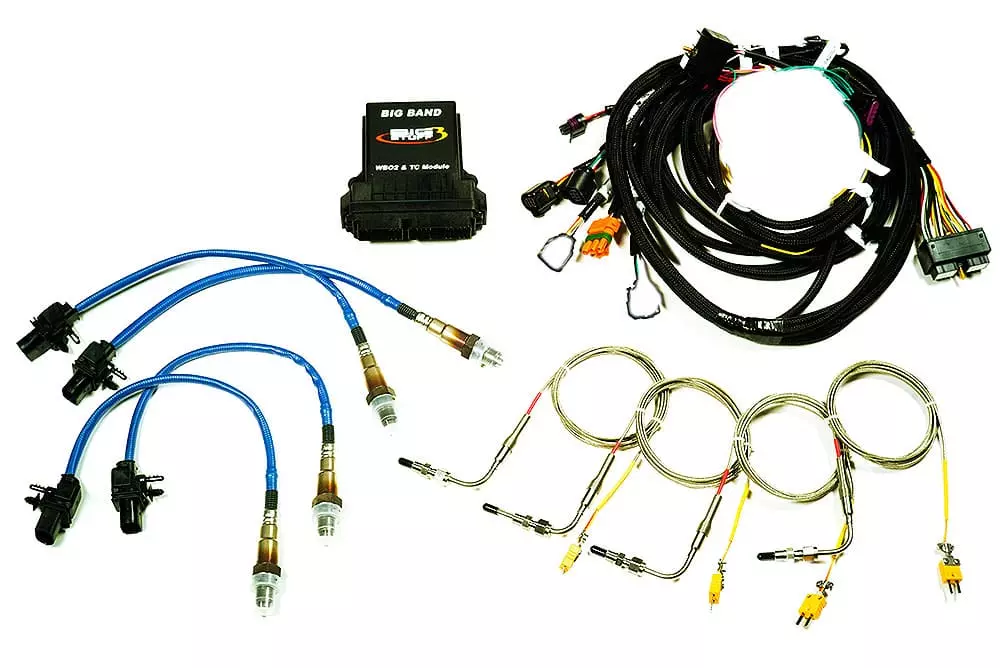

Sensor Wire Harness – Custom, OEM & Standard Solutions for All Sensor Types

Sensor Wire Harness is a key component for connecting all kinds of sensors and control systems, which is widely used in automotive, industrial, medical and smart devices. It ensures accurate and stable signal transmission, and is an indispensable connection solution for data acquisition and automation control.Linkwings provides standard and customized sensor wire harnesses to meet different environments and functional requirements, and supports fast delivery and OEM services.

Custom Sensor Wire Harness from Wire Harness Manufacturer —— Linkwings

In various industrial automation, automotive electronics, medical equipment and smart terminals, sensor wire harnesses as a key component of signal acquisition and transmission, the stability, shielding and plug matching put forward higher requirements. linkwings as a professional wire harness manufacturer, specializing in providing Custom Sensor Wire Harness solutions. We can develop customized wire harnesses that precisely match the customer’s drawings, sensor interfaces, electrical parameters and usage environment.

We support customized configurations such as multi-conductor wires, shielded structures, waterproof plugs, high temperature materials and more. Our products are widely used in temperature, pressure, position, photoelectricity and other types of sensor systems, to provide customers with stable, safe, high adaptability of the connection guarantee.

Tpyes of Seneor Wire Harness

Sensor harnesses can be categorized into a variety of types depending on the type of sensor they are connected to, the environment in which they are used, their electrical characteristics and the form of the interface.

Single-Channel Sensor Harness

- Ideal for accessing single sensor devices such as temperature sensors, position switches, flow meters, etc.

- Typically 2- or 3-pole construction with standard terminals or mini-plugs

- Widely used in industrial control systems and simple detection modules

- Characteristics: simple structure, easy to install, can be quickly customized in batches

Multi-Channel Sensor Harness

- For simultaneous connection of multiple sensors (e.g. a combination of temperature/humidity/pressure)

- Available as a multi-conductor structure or as a multi-conductor cable harness summarized to a master plug

- Commonly used in vehicle engine control systems, data acquisition modules (DAQ)

- Features: centralized routing, space reduction, improved wiring efficiency

Shielded Sensor Harness

- Used in EMI (Electromagnetic Interference) sensitive scenarios, such as high-speed signals, weak electrical signal transmission

- Aluminum foil + braided shielding, external ground or controller GND connection

- Typical applications: Hall sensors, signal amplifiers, pressure transmitters, etc.

- Characteristics: Strong signal integrity, high anti-interference capability, suitable for industrial/automotive control systems.

Waterproof Sensor Harness

- Equipped with IP65~IP68 rated waterproof plug and sealing treatment

- Suitable for outdoor, motor compartment, high humidity or underwater operating environment

- Common scenarios: ABS sensors, camera modules, agricultural sensors, outdoor monitoring equipment

- Features: Tightly sealed, corrosion-resistant, suitable for harsh climate and rainy areas

High-Temperature Sensor Harness

- Use of high temperature resistant insulating materials such as silicone wire, FEP/PTFE insulated wire

- For use in engine compartments, heating systems, industrial furnaces or high-temperature environments

- Application examples: oxygen sensors, exhaust gas temperature sensors (EGT), etc.

- Characteristics: heat-resistant ≥ +150°C, soft structure, good aging resistance

Standard Industrial Sensor Harnesses

- M8, M12 round plugs, in line with industrial automation standards

- Plug pre-assembled injection molding, support thread locking, code positioning

- Applied to PLC, industrial robot, automation equipment connection

- Characteristics: strong versatility, easy to replace, high industrial field compatibility

Technical Specifications

| Item | Specification Range |

|---|---|

| Conductor Material | Pure Copper / Tinned Copper / Silver-Plated Copper |

| Wire Cross Section | 0.2mm² – 1.5mm² (22AWG – 16AWG) |

| Number of Conductors | 2-core / 3-core / 4-core / multi-core (customizable) |

| Rated Voltage | DC 5V / 12V / 24V (customizable for other requirements) |

| Rated Current | Typically < 5A (depends on sensor load) |

| Insulation Material | PVC / XLPE / TPE / Silicone / FEP / PTFE |

| Cable Jacket | Single-layer / Double-layer / Corrugated Conduit / Braided Sleeve |

| Shielding Option | Aluminum Foil / Tinned Copper Braid / Dual Shielding |

| Connector Type | JST / TE / Molex / M8 / M12 / Custom Connectors |

| Protection Level | IP65 / IP67 / IP68 (depending on connector & sealing structure) |

| Operating Temperature | -40℃ ~ +105℃ (High-temp version up to +150℃ or higher) |

| Cable Colors | Black / Grey / Yellow / Red / Multicolor (with custom printing) |

| Testing Requirements | Continuity / Hi-pot / Pull Force / Insertion-Extraction Test |

| Compliance & Standards | RoHS / REACH / CE / UL (available upon request) |

Key Features:

- High compatibility: Suitable for a wide range of sensor types, including temperature, pressure, position, oxygen, speed, radar, etc.

- Precise connection: accurate plug alignment, smooth plugging and unplugging, with anti-dumbing structure, support OEM/ODM interface matching.

- Stable signal: optional shielding layer design reduces electromagnetic interference and ensures accurate and reliable data transmission.

- Strong protection: supports waterproof, dustproof, oilproof and high temperature resistant structure, suitable for outdoor and complex working conditions.

- Convenient installation: cable length, plug direction, numbered labels can be customized for easy on-site wiring and maintenance.

- Strong customization ability: support sampling, structure optimization, and batch delivery according to drawings to meet the needs of system integration.

What is Sensor Wire Harness?

Sensor Wire Harness is a specialized cable assembly used to connect sensors to the control system. The main purpose of this type of wire harness is to transmit power, signals and control commands to ensure stable and accurate transmission of sensor data to the main control unit (e.g. ECU, PLC or motherboard).

These harnesses usually consist of multi-core wires, shields, terminals, connectors, waterproof encapsulation, jackets, etc. And in order to cope with the complex working conditions in various industrial and automotive environments, they are usually characterized by good anti-interference, waterproofing, high temperature resistance, and plug-and-play reliability. Unlike ordinary cables, sensor harnesses have higher requirements for signal integrity, electromagnetic shielding, protection level and structural accuracy.

Typical Application of Sensor Wire Harness

Sensor harnesses are widely used in various systems that require signal acquisition, control feedback and data transmission. Its role is to provide power for the sensor, communication interface and the collected signals are accurately transmitted to the control center. Depending on the industry, the structure, interface, shielding and protection level of the wiring harness also varies.

Automotive Electronic Systems

Sensor wire harnesses are widely used in automobiles for ABS sensors, oxygen sensors, temperature sensors, tire pressure monitoring and self-driving radar systems. It is mainly responsible for collecting and transmitting critical driving data, and is required to be waterproof, vibration-proof and high temperature resistant.

Industrial automation equipment

In factory automation equipment, the sensor harness connects a variety of position, proximity and photoelectric sensors with PLC controllers. It ensures real-time monitoring of equipment operating status and is characterized by anti-interference, high flexibility and standardized interfaces.

Medical Device Systems

Sensor harnesses in medical instruments are used to connect physiological monitoring modules such as body temperature, heart rate, blood pressure, etc.. They need to meet the requirements of high precision, strong shielding, small wire diameter and biocompatibility.

New Energy and Smart Hardware

In new energy vehicles, drones, smart homes and other devices, Sensor wire harness is used to connect battery management systems, attitude sensors and environmental monitoring modules, supporting miniaturization, multi-channel and lightweight structural design.

Agriculture and Outdoor Equipment

Sensor harnesses used in intelligent agriculture and outdoor equipment mainly serve monitoring scenarios such as soil moisture, light, flow, etc., and need to be well waterproof and corrosion-resistant to adapt to the long-term working environment in the field.

Why Choose Linkwings for Sensor Wire Harness Solutions?

In the field of sensor wiring harnesses, it is crucial to choose a wiring harness manufacturer with reliable technology, flexible delivery, and strong customization capabilities. linkwings has been specializing in the wiring harness industry for more than 10 years, with complete capabilities from product design, process sampling, to volume manufacturing. As a result, Linkwings is trusted by OEMs, system integrators and engineering buyers worldwide.

✅ 1. Professional Sensor Wire Harness Manufacturing Experience

Linkwings has been providing customized sensor wire harness solutions for automotive, industrial, medical, new energy and other industries for a long time, we are familiar with all kinds of sensor types, electrical specifications and interface requirements, and we can quickly respond to all kinds of complex scenarios.

✅ 2. Strong Customization and Engineering Capability

We support the development of Sensor Wire Harness according to drawings, functional requirements or samples, and flexibly configure the number of cores, plug brands, shielding methods, waterproof levels, etc., to meet the customization needs from standard pairs of plugs to the complexity of the one-to-many wiring harness structure.

✅ 3. Strict quality control and complete certification

factory passed IATF 16949, ISO 9001 quality system certification, products support RoHS, REACH, CE, UL and other international compliance standards, all wire harnesses 100% passed pass the pass-through test and critical point inspection before leaving the factory.

✅ 4. Fast Delivery and Small Batch Sampling

supports small batch ordering, samples can be produced in 3 days at the earliest, and standardized products are always in stock, which is suitable for engineering research and development, quick replacement, modification and trial installation, etc., and reduces the cost of trial and error and the development cycle of the customers.

✅ 5. Global Service and Technical Support

Linkwings products are exported to Europe, America, Southeast Asia, the Middle East and other regions, providing Chinese and English drawings, technical documents, wiring guidance and after-sales support to help customers efficiently complete the whole process from selection to installation.

FAQs About Linkwings Sensor Wire Harness

1. What is the difference between a Sensor Wire Harness and a regular wire harness?

Compared with ordinary wire harnesses, sensor wire harness requires higher signal integrity, anti-interference, waterproof sealing and plug structure precision. Therefore, it is widely used in high reliability scenarios such as automotive electronics, industrial automation, and medical equipment.

2. Can you customize Sensor Wire Harness? What is the MOQ?

Linkwings supports customization based on customer supplied drawings, samples or interface requirements. Including wire length, color coding, number of cores, plug type, shielding structure, protection level and so on.

Our customization service supports low MOQ production with no MOQ restrictions at the sample stage. It is suitable for small quantity sampling and quick trial production, and also supports bulk supply at a later stage.

3. What types of sensor plugs do you offer? Do you support waterproof construction?

We can provide common plug brands such as JST, TE, Molex, AMP, Deutsch, M8/M12 industrial interface, as well as customized terminal solutions.

Depending on the usage environment, we can choose waterproof IP65/IP67/IP68 package structure. Including injection molded jacket, rubber sealing, thread locking and other forms, suitable for outdoor, engine compartment, high humidity or complex working conditions.

4. What industries can sensor harnesses be used in? What certifications do your products meet?

Our Sensor Wire Harness has been widely used in automotive, industrial equipment, medical devices, intelligent hardware, new energy systems, agricultural control and many other fields.

Our products are available with RoHS, REACH, CE, UL, IATF 16949 certifications and test reports to meet the requirements of export markets and industrial standards.

5. I am not sure which harness to use for my sensor, can you provide technical support?

Of course you can. Simply provide us with your sensor model, application, electrical parameters, or a sample of your existing wiring harness, and our team of engineers will assist you with structural evaluation, selection recommendations, or custom development.

We can also provide wiring diagrams, technical data, packaging recommendations, and prototyping support to ensure that your design and installation are completed quickly and smoothly.