Top 10 Automotive Wire Harness Manufacturers and Suppliers 2026

Home » Top 10 Automotive Wire Harness Manufacturers and Suppliers 2026

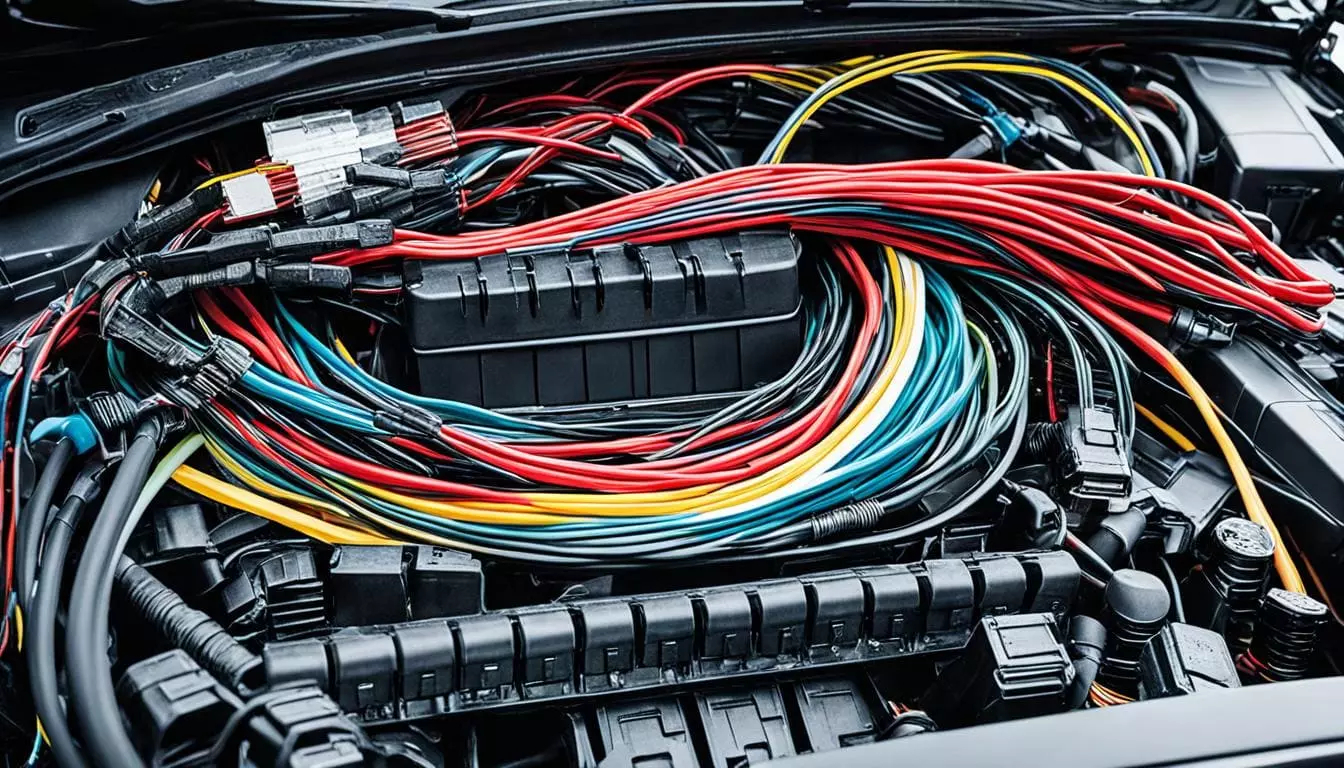

In the automotive industry, whether it is a traditional fuel vehicle, hybrid vehicle or pure electric vehicle, automotive Wire Harness is always the key core of the electrical system. It is like the “neural network” of the car, responsible for signal transmission and power distribution, which directly affects the stability and safety of the whole car. Choosing a reliable automotive wiring harness manufacturer or supplier is not only a matter of cost, but also a matter of project delivery, product quality and even follow-up support.

As an engineer, I have contacted a lot of domestic and foreign wiring harness manufacturers in the past few years, and have had successful cooperation, but also stepped on some pits. In today’s article, I will share 10 automotive wiring harness manufacturers and suppliers worth paying attention to in 2026, based on actual cooperation experience and industry observation. Whether you are going to sample in small quantities or prepare for large-scale procurement, you can find a quality partner for your project from them.

How do I filter these automotive wiring harness manufacturers and suppliers?

In the past few years, I have been involved in several automotive electronics, electric drive systems and new energy vehicle projects. Therefore, I deeply realize that choosing the right wiring harness supplier not only saves money, but also saves a lot of time and rework costs. In the actual procurement process, it is not uncommon for engineering teams, small car manufacturers or foreign buyers to encounter inconsistent quality, delivery delays and incomprehensible drawings.

When choosing the right automotive wiring harness manufacturer and supplier, I generally consider the following:

- On-site visits or cooperation experience

- Product certified to ISO 9001 / IATF 16949, etc.

- Support for customized/quick prototyping/EV harness solutions

- Response time, delivery time, after-sales support

- Export experience (North America/EU compliant)

Top 10 Automotive Wire Harness Manufacturers and Suppliers 2026

| No. | Company Name | Headquarters | Established | Ideal Customer Type |

|---|---|---|---|---|

| 1 | Yazaki Corporation | Japan | 1941 | Major OEMs |

| 2 | Linkwings Electric | China | 2010 | All customers with high demand for wiring harnesses |

| 3 | Aptiv (Former Delphi) | Ireland | 1994 | EV and smart platforms |

| 4 | LEONI AG | Germany | 1917 | European OEMs / Premium Vehicles |

| 5 | Furukawa Electric | Japan | 1884 | Japanese brands / Utility vehicles |

| 6 | KWS (Kyungshin) | China | 2003 | Domestic EV startups / OEMs |

| 7 | Motherson Sumi | India | 1986 | Cost-efficient global programs |

| 8 | Nexans Autoelectric | Germany | 1930 | Integrated European EV programs |

| 9 | PKC Group | Finland | 1969 | Heavy trucks and commercial use |

| 10 | Lear Corporation | USA | 1917 | Complete vehicle platforms / Interiors |

1. Yazaki Corporation

Headquarters Location: Shizuoka Prefecture, Japan

Established: Founded in 1941

Scale of Production: The Yazaki Group is currently one of the world’s largest manufacturers of automotive wiring harnesses. The company has branches in more than 45 countries around the world, with more than 250 manufacturing plants and about 240,000 employees. Annual revenues have remained stable at more than US$16 billion, and the company has customers in all major automobile manufacturers.

Company Profile: The Yazaki Group specializes in multiple product categories such as wiring harnesses for automobiles, power distribution systems, connectors, instruments, and battery cables. The company specializes in passenger car main harnesses, high-voltage harnesses for electric vehicles, data transmission harness systems, and platform management of complete vehicle harnesses (e.g., modular harnesses). In addition to this, the Yazaki Group is fully certified to IATF 16949, ISO 14001, and ISO 45001, and holds certificates for automotive compliance standards such as UL, RoHS, etc., in a number of countries and regions.

Yazaki’s strength lies not only in its size, but also in the coordination and technical depth of its global supply chain. The company has a strong engineering team that can customize electrical architecture solutions for major OEMs, and has synchronized R&D centers in multiple countries for fast response time.

For people:

Large OEMs, Tier 1 system integrators, and large customers seeking stable global delivery and high reliability.

Website: www.yazaki-group.com

2. Linkwings Electric

Headquarters Location: Shanghai, China

Founded: 2010

Capacity Scale: Linkwings is an integrated wire and cable manufacturer. Its business covers more than 40 countries and regions around the world. Its Denso Business Unit specializes in automotive wire harnesses, connectors and modular wiring solutions.

Company Profile: Linkwings excels in high-voltage wiring harnesses (especially HV systems for EV platforms), anti-interference signal cables, battery management wiring harnesses, and EMC-optimized cable design. Products cover electrical connection solutions for conventional fuel vehicles, electric vehicles, and hybrid vehicles. In addition, Linkwings has international certifications such as IATF 16949, ISO 9001, ISO 14001, UL, RoHS, REACH, etc., and meets the standards of North America, the European Union, Asia, and other markets.

Linkwings has a natural advantage in high-temperature, high-voltage and corrosion-resistant cables based on its strong material science background. Linkwings’ customers are mainly companies that use wire harnesses around the world.

Suitable for:

New energy automotive companies in need of high-voltage/high-temperature cable solutions, OEMs or Tier 1 customers seeking long-term support.

Website: www.linkwingselec.com

3. Aptiv (formerly Delphi)

Headquartered in: Dublin, Ireland

Founded: 1994

Capacity: Aptiv specializes in automotive electrical architecture and intelligent driving solutions with 120+ manufacturing and engineering centers worldwide.

Company Fact: Aptiv focuses on technology frontiers such as centralized electrical architectures, high-speed data transmission harnesses, central gateway wiring systems, EV power platform cables, and is a key enabler of software-defined automotive architectures (SDA) and zonal architectures. The company has international certifications such as IATF 16949, ISO 26262 and ISO 9001. It is also compliant with GDPR, RoHS, REACH and other compliance requirements.

Aptiv’s greatest strength is its ability to innovate. Aptiv is a leader in smart driving, modular wiring systems and high-speed Ethernet harnesses. Its highly automated factories work closely with software teams to provide end-to-end system integration.

Suitable for:

Autonomous driving project parties, smart cockpit development companies, electric vehicle OEMs, and cross-border vehicle building project teams of technology companies.

Website: www.aptiv.com

4. LEONI AG

Headquartered in: Nuremberg, Germany

Founded: 1917

Capacity: LEONI is one of Europe’s oldest suppliers of automotive cable systems. It has more than 90 production and service locations worldwide, mainly in Europe, the Middle East and Asia.

Company Profile: LEONI specializes in lightweight wiring harnesses, high integration density cabling, and multi-signal composite cable solutions.LEONI’s strengths are in precision manufacturing and engineering optimization. LEONI is especially suitable for high-end models with stringent requirements on wiring harness complexity and space utilization. LEONI also has an in-depth layout in the research and development of new materials.

Suitable for:

European car companies, luxury brand platforms, customers with high requirements for lightweight structure and aesthetic installation.

Website: www.leoni.com

5. Furukawa Electric

Headquartered in Tokyo

Established: 1884

Capacity: Fujitsu Tenka has several production bases in Japan, Thailand, China, and Mexico.

Company Profile: FUJITSU TEN is known for its continuous optimization of cable performance under extreme operating conditions. Our products are widely used in special construction vehicles, mining and transportation equipment, and rail transportation, where the reliability of electrical systems is of the utmost importance.

Suitable for:

Construction machinery manufacturers, rail transportation system integrators, Japanese commercial vehicle platforms, and other customers with stringent requirements for cable stability.

Website: www.furukawa.co.jp

6. Kyungshin Denso

Location: Korea

Founded: 2003

Company Profile: KWS specializes in vehicle wiring harnesses, on-board charging systems (OBC), battery connectivity systems (BMS), high voltage connector systems, etc. KWS has mature technology in the field of low voltage + high voltage hybrid wiring for new energy passenger cars and commercial vehicles. KWS has mature technology in the field of low-voltage + high-voltage hybrid wiring for new energy passenger cars and commercial vehicles.

KWS has a clear advantage in terms of local response time and customization capabilities. The company combines global Tier 1 experience with the flexibility to respond to the fast pace of China’s new energy industry.

Who should attend:

New energy startup brands, OEMs that need fast prototyping and small batch supply, and programmers that are looking for a CJK cooperative OEM platform.

7. Motherson Sumi Systems

Headquartered in New Delhi, India

Established: 1986

Capacity: Motherson Sumi is the world’s fifth largest manufacturer of automotive wiring harnesses. Part of the Samvardhana Motherson Group in India, it has operations in 41 countries.

Company Facts: Motherson provides passenger car main wiring harnesses, cabin electrical systems, interior modular cable systems, and integrated tooling and assembly services in multiple countries, with strong cost control, multinational compliance, and a one-stop supply chain. These features make Motherson particularly well suited for high-volume, multi-vehicle, multi-market simultaneous development projects.

Suitable for:

Global OEMs, OEMs with multi-country factories or export programs, and cost-sensitive customers with large projects that require stable supply.

Website: www.motherson.com

8. Nexans Autoelectric

Headquartered in: Plauen, Germany

Founded: 1930

Capacity: Manufacturing and R&D centers in Germany, Romania and the Czech Republic, with about 12,000 employees.

Company Fact: Nexans Autoelectric specializes in highly integrated automotive electrical system wiring. This includes high-voltage cables, CAN bus cabling, and integrated systems for multiplexed control modules, especially for compact EV platforms.

Known for its precision manufacturing and customized R&D, Autoelectric is experienced in serving European premium brands and has worked with Volkswagen, Audi and BMW on new energy high-voltage connectivity systems.

Suitable for:

European OEMs, projects focusing on the aesthetics and structural integration of wiring systems, and high-end electric vehicle projects.

Website: www.nexans.com

9. PKC Group

Headquartered in: Helsinki, Finland

Founded: 1969

Capacity: specializes in commercial vehicle and heavy-duty wiring harness systems. its acquisition by the Motherson Group in 2017 resulted in a significant increase in its global capacity.

Company Facts: PKC provides highly durable wiring harness solutions in the areas of heavy trucks, agricultural machinery, buses and rail vehicles. Specializing in modular wiring harnesses and redundant wiring technology design.

PKC products are vibration, heat, and oil resistant and are suitable for wiring harness arrangements in harsh environments. The engineering team is experienced and familiar with a wide range of industrial vehicle wiring configurations. PKC also serves international brands such as Volvo Trucks, John Deere, and Navistar.

For people:

Construction machinery manufacturers, heavy-duty commercial vehicle OEMs, rail transportation integrators, agricultural equipment manufacturers.

Website:www.pkcgroup.com

10. Lear Corporation

Headquartered in: Southfield, Michigan, USA

Founded: 1917

Capacity: Lear is a leading global supplier of automotive cockpit and electrical systems, with 250+ manufacturing and technology centers in more than 40 countries around the world.

Company Fact: Lear provides passenger car main wiring harnesses, intelligent cockpit connectivity systems, battery management wiring harnesses, modular instrumentation wiring, and more. In recent years, the company has continued to increase its efforts in intelligent wiring harness platforms and wireless control systems.

In addition, Lear has a complete vertical integration capability from design to system integration. Wiring optimization, space minimization, weight control and smart module integration can be achieved within the cockpit platform.

Suitable for:

Passenger car manufacturers, smart cockpit system integrators, export-oriented OEMs in North America.

Website: www.lear.com

How to choose the right automotive wiring harness supplier for a startup or low-volume project?

For most startups, technology transition teams, or small EV programs that are just getting started, wiring harness procurement is a “seemingly simple but complicated” hurdle. Unlike large companies, startup teams face the reality of limited budgets, tight development cycles, and iterative design.

So, in the face of the many automotive wiring harness manufacturers on the market, which are suitable for startups or small-volume projects? And how should you screen them? Here are some of the key lessons and recommendations I’ve summarized:

1. Don't blindly pursue “big factories” - choose “suitable factories”

Many startups want to find global TOP5 suppliers at the beginning, thinking that “big factory equals reliable”. But in fact, large wiring harness factory usually:

- More concerned about high-volume, long-term orders

- High MOQ, usually more than 500-1000 sets.

- Long sampling cycle, complex communication process

- Prefer to cooperate with OEMs and Tier 1s, and do not accept customization requirements from small and medium-sized customers.

For start-up projects, medium-sized, flexible and responsive “specialized harness factories” with a high degree of technical cooperation are a better choice. Although these factories are not in the “Fortune 500” list, but can give you what you really need in the early stage: fast response, support for sampling, small batch production, engineering optimization suggestions.

2. Technical cooperation ability is far more important than price

Wiring harnesses for start-up projects are often in the development stage and go through constant changes and iterations, for example:

- Adding new sensors, ECUs, and changing the wiring paths.

- Changing connector brands (e.g. from TE to Molex)

- Adding a high voltage harness or CAN communication harness, the shielding design has to be changed.

This is where a wiring harness factory that understands engineering and doesn’t just quote is critical. Not only will they be able to read your drawings, but they will be able to take the framework of the system you provide:

- Recommend more appropriate wire gauge, jacket (e.g. TXL/GXL/SXL)

- Optimize costs (e.g., wire splitting methods, terminal multiplexing, tape wrap vs. bellows)

- Alert you to possible design risks (e.g. signal interference, wire length limitations, voltage drop)

3. Recommended preference is given to “specialized harness factories with experience in automotive projects”

Not all wiring harness factories are capable of handling automotive projects. You should prioritize those that do:

- Specialize in automotive wiring harnesses

- Familiar with IATF 16949 requirements, even if certification is not mandatory

- Have experience working with startup automotive companies

- Able to support NDA signing, 2D/3D drawing receipt and archiving

List of questions: What do I need to prepare before contacting a Car wiring harness supplier?

| Category | Specific Content | Notes / Tips |

|---|---|---|

| 📐 Drawings | Do you have 2D/3D files? (PDF, DWG, STEP formats) | Attach photos or installation sketches if available |

| 🔌 Connectors | Are specific brands required (e.g., TE, Molex, Yazaki)? Any part numbers? | Provide samples or ask for equivalents if uncertain |

| 🔋 Electrical | Voltage and current range? Signal wires, HV cables, shielding needed? | Clearly label high-voltage requirements for EV projects |

| 🔧 Mounting | Any routing paths, fixing clips, tape/wrapping preferences? | Add vehicle layout or dimensional constraints if needed |

| 🧪 Material | Do materials need to comply with UL, RoHS, REACH? Required insulation rating? | Mention if heat resistance >125°C is necessary |

| 📦 MOQ / Phases | What’s the trial quantity? Yearly estimate? Prototype-only or mass production plan? | Explain if small batch now, scale-up later |

| ⏱ Lead Time | When do you need samples? Any SOP deadlines or milestones? | Be specific: e.g., “sample within 2 weeks,” “SOP in Aug” |

| 📜 Documents | Do you need PPAP, BOM, test reports, CO, invoice, etc.? | For export, mention bilingual docs or specific formats |

| 🔐 NDA | NDA required? Is the project confidential or under development? | Recommend signing NDA before detailed discussion |

| 🧩 Tech Support | Do you need routing optimization, design feedback, or substitutions? | Especially useful for startups or concept-stage builds |

Why choose Linkwings as your automotive wiring harness manufacturer?

When choosing an automotive wiring harness manufacturer, many engineers and purchasing leaders are most concerned about three things: whether the quality is reliable, whether the communication is smooth, and whether it can support customization and fast delivery. As a China-based manufacturer specializing in automotive wiring harness systems, Linkwings exists for this very reason.

We serve not only traditional OEM customers, but also a large number of fast-growing new energy vehicles, engineering vehicles, smart mobility and overseas projects. Whether you need 10 sets of sample harnesses for trial installation, or are ready to deliver thousands of sets in bulk, we can provide you with flexible, efficient and professional solutions.

Why Choose Linkwings?

- Specialized in automotive wiring harness: We have experienced automotive wiring harness engineering team. We are familiar with the whole vehicle wiring, powertrain, cockpit, BMS and other types of automotive wiring harness system. And we support low-voltage + high-voltage hybrid wiring, CAN/LIN bus wiring, electromagnetic compatibility (EMC) optimization and so on.

- Small quantities are also valued: the MOQ can be as low as 10 sets, the fastest sampling cycle of 3 days. Support customized drawings, physical reverse modeling, sample reproduction.

- Perfect certification system and quality control: the factory has passed IATF 16949 and ISO 9001 certification. Strictly execute the crimping, testing, packaging and factory inspection of each wire harness, and support the provision of PPAP, BOM, inspection report and other documents.

- Experienced in export, no communication barriers: We have a professional international business team, familiar with the export process and standards in North America, Europe, Middle East and other markets.

- One-stop service: From harness selection, terminal matching, alignment optimization, to sample production, on-site trial installation, and later mass production, we provide end-to-end technical support. Help you reduce the risk of R&D and delivery.

FAQs about Automotive Wire Harness Manufacturers and Suppliers

Q1: I'm a startup car company, are there any suppliers who are willing to take small volume orders like ours?

A: Sure, but you need to choose the right manufacturer.

Some large wiring harness manufacturers (e.g. Yazaki, Sumitomo) mainly serve OEMs and Tier 1, usually with high MOQ and complicated process, which is not very suitable for startups or small projects.

It is recommended that you prioritize medium-sized wiring harness factories with experience in automotive projects, who are more flexible. They not only support small-lot sampling of 10~50 sets, but also provide services such as drawing optimization and recommendation of alternative materials, which is very suitable for teams that are just starting out.

As a specialized automotive wiring harness manufacturer, Linkwings can provide custom automotive wiring harness solutions for a variety of small projects and harness applications.

Q2: If I don't have the wiring harness drawing, can I entrust the supplier to help me design?

A: Yes, provided that you provide enough information.

Many professional harness manufacturers have engineering teams that can assist in the design of preliminary harness drawings based on the information you provide such as wiring paths, functional requirements, and photos of connectors. This is especially helpful for startups without a complete R&D system. However, it is recommended to sign an NDA (Non-Disclosure Agreement) to ensure the intellectual property safety of the design results.

Q3:How long is the wire harness proofing cycle?

A: Proofing time is generally 3~10 working days.

It depends on the complexity of the project, whether it is a standard part (e.g. TE/Molex common terminals) and the manufacturer’s ability to prepare materials.

Experience suggests the following:

- Simple low voltage wiring harness with all standard parts → 3~5 days for sampling

- With high-voltage, customized connectors, shielding layer, etc. → 7 ~ 10 days

- If mold development or special terminals are involved, the lead time may be longer.

Q4: My project is abroad but I want to manufacture the wiring harness in China, is this reliable?

A: Absolutely, many Chinese wiring harness factories already have international delivery capabilities.

The key is to choose manufacturers with mature experience and standardized processes to ensure that they have:

- English drawing recognition capability

- Export packaging and protection capabilities

- Overseas transportation experience (able to provide ocean/air invoices, customs documents, etc.)

- Ability to accept remote sampling feedback, video acceptance, third party inspection and other processes

If you need, we (Linkwings) can assist you in finding a harness partner with cross-border capabilities.

Contact Automotive Wire Harness Manufacturer Now!

Whether you’re a head of procurement, a technical supervisor, or you’re just starting an automotive project, finding an automotive wiring harness manufacturer that understands your needs and responds quickly is where the real cost savings begin.

At Linkwings, we provide our customers with stable, traceable, and customization-enabled automotive wiring harness solutions. Whether you’re looking for a quick prototype or volume supply, we offer engineer-level support. Contact us today for custom automotive wiring harnesses.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In