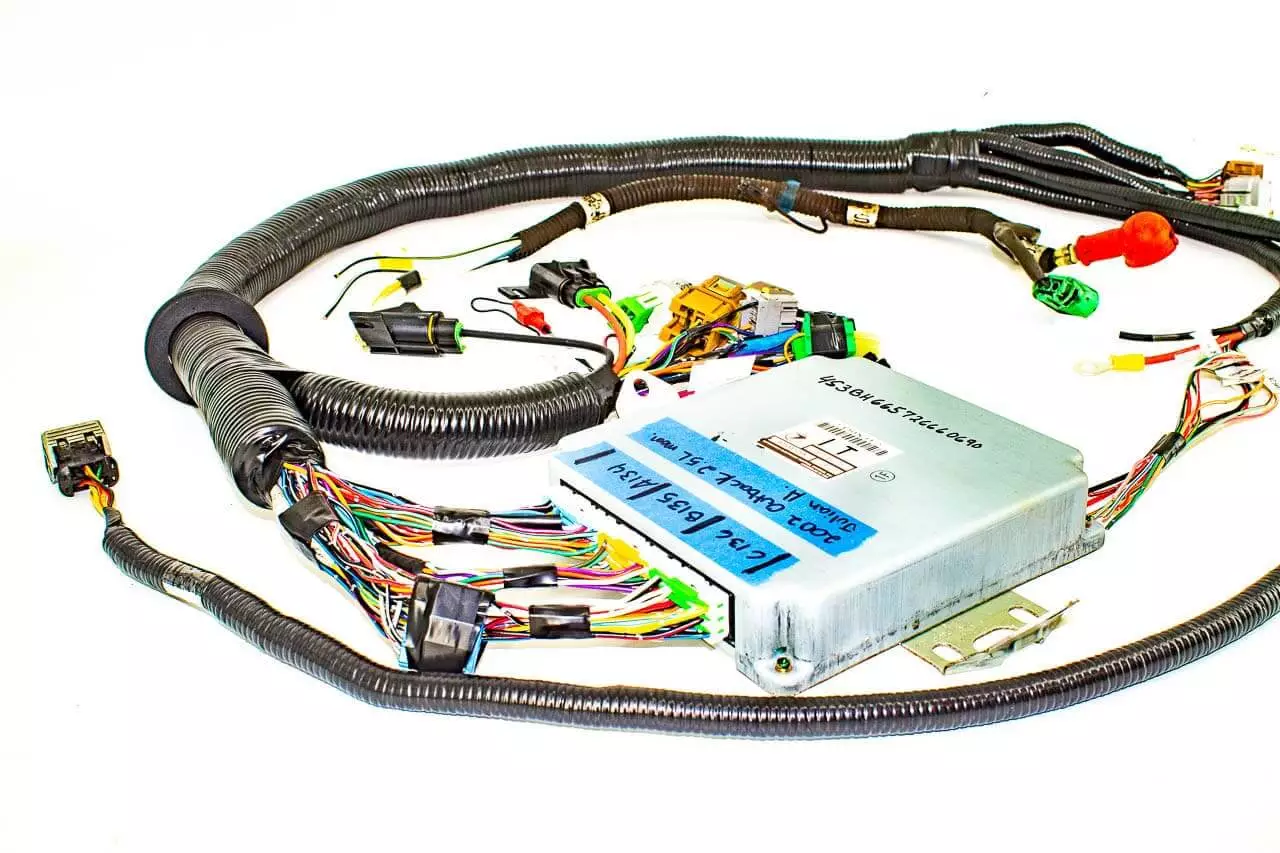

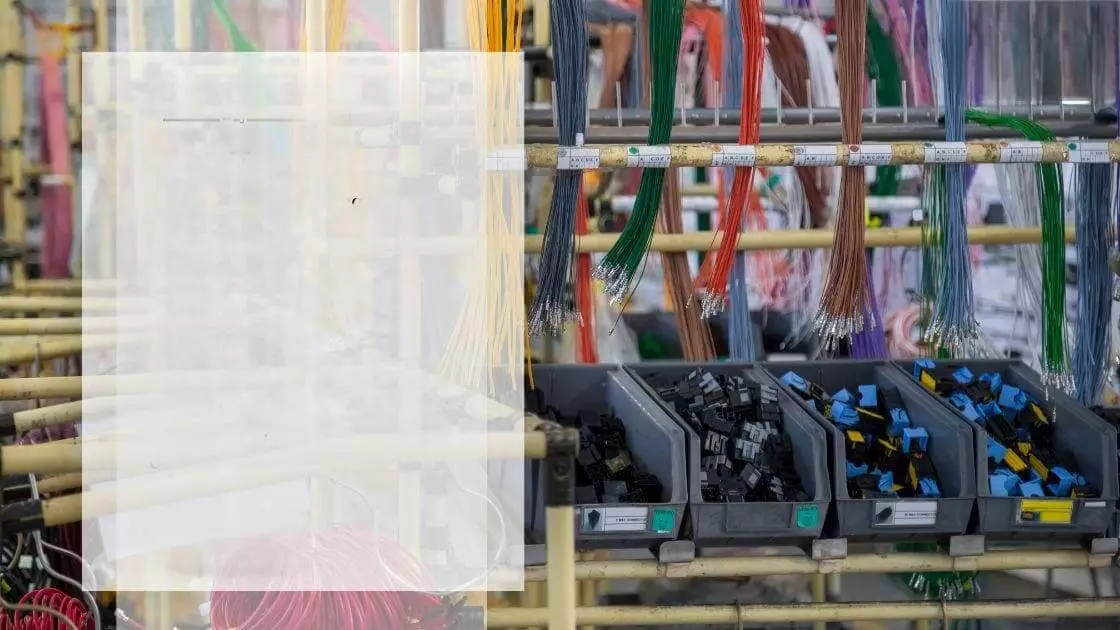

In many devices, we can often see a variety of colors of cables are neatly bundled together. Even sometimes covered with bellows or tape, which is the main character we want to talk about today – Wire Harness.

Many engineers and business owners ask, “What is a wire harness used for?” Is it just for aesthetics? Or is it just to make wiring easier? In fact, wire harnesses play a vital role in automotive, industrial equipment, robotics, electronics, and more.

What are Wire Harnesses?

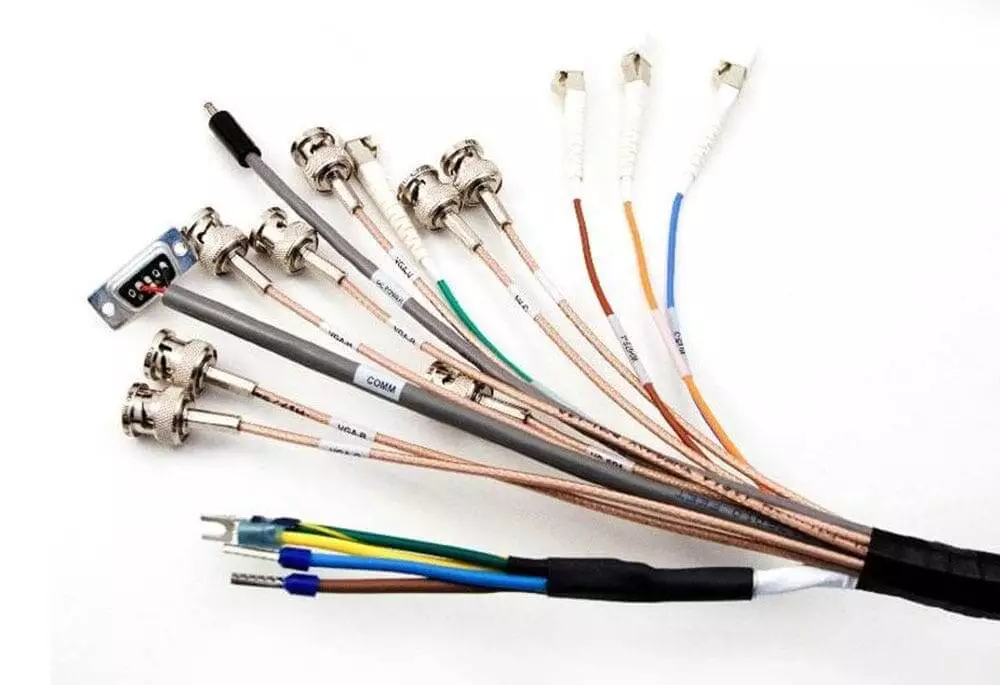

Wire Harness, sometimes referred to as a harness assembly, cable bundle, wiring system. It is essentially a group of wires and cables combined with connectors used to transmit power and signals.

Definition of Wire Harness in Application Engineering:

A wire harness is the combination of multiple wires, terminals, connectors, and protective materials into a complete systematic wiring solution that serves electrical control and energy transmission.

Wire Harness Components

| Component | Function Description |

|---|---|

| Wire | Transmits current or signals; typically copper core with insulation |

| Terminal | Crimped onto wire ends for secure electrical contact |

| Connector | Modular plug/socket interface for easy connection/disconnection |

| Sleeving / Sheath | Provides protection (e.g., tape, corrugated tube, heat shrink) |

| Clip / Fastener | Secures harness to prevent vibration and wear |

| Label / Marker | Identifies each wire’s function or position for easy maintenance |

Core uses of wire harnesses

The core purpose of a wiring harness is to realize the efficient, safe and structured transmission of “signal + power”.

It is not optional, not decorative, but a system can be the basis for long-term stable operation. Without it, any complex equipment will fall into electrical chaos; with it, the system is organized, controllable and maintainable.

In the automotive, robotics and industrial control equipment projects, I have seen too many “just pull the wire, do not design the wiring harness,” the ultimate failure of the program: signal confusion, unstable power supply, installation rework, after-sales frequent. The real professional harness design, often fundamentally improve the safety, efficiency and maintainability of the system. Here are the four core purposes of a wiring harness:

1. Data & Control Signal Transmission

The first key use of a wiring harness is to transmit various types of signals in a control system. Included:

- Sensor data (temperature, speed, pressure, position)

- Control commands (switch, brake, steering, lift, etc.)

- Communication protocols (CAN, LIN, Modbus, Ethernet)

- These signal lines often use thin wires of 0.3-1.0 mm², which require anti-interference, impedance matching and strict wiring rules (e.g. twisted pairs, zoned alignments, etc.).

Engineering experience sharing: In one of our warehouse robotics projects, the use of unshielded signal wires resulted in unstable control signals. After subsequent replacement with shielded twisted-pair cables and adjustment of the alignment direction, the failure rate dropped by more than 90%.

2. Power Distribution

The wiring harness is the “blood vessel” of the system’s electrical energy, responsible for transferring power from the main power module to the individual actuators. For example:

- Motors, fans, heaters, lights, cameras, drive units

- Electronic control modules (ECU, PLC, controllers)

- Electrical power harnesses usually have large wire diameters (e.g. 2.5-6 mm²). The voltage drop needs to be calculated according to current, voltage and wire length to avoid overheating and power loss.

Reminder: Smaller wire diameter is easy to heat up, larger wire diameter is a waste of cost, and must be accurately matched to the actual current.

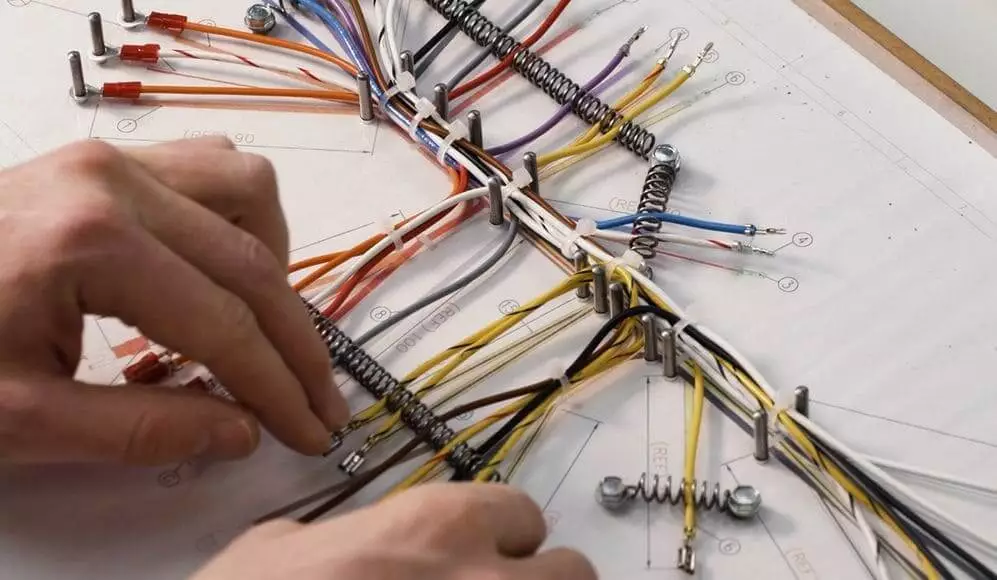

3. Modular Routing & Organization

The greater value of wire harnesses over individual wires is to make wiring systematic and structured. For example:

- Dozens of wires will be synthesized into a wire harness, according to the module branch wiring (main line → branch line)

- Improve assembly efficiency, reduce the error rate

- Clearer, tidier, easier to maintain and replace after installation

Not long ago one of our customers found us. He initially used loose wires, and every time he changed a part, he had to find the wires and wiring again, and the maintenance time was up to 4 hours. After we recommended him to change to modular wiring harness, it only takes 15 minutes to change parts.

4. Protection & Reliability

Wiring harness not only transmits energy, but also assumes the role of protecting wires, prolonging service life and improving system stability:

- Outer covering: bellows, heat shrink tubing, braided mesh to prevent wire abrasion, short circuits

- Shielding layer: to avoid high-voltage current interference signal (especially CAN, LIN, etc.)

- Connectors: with waterproof, dustproof, anti-wrong plug function (IP67 rating)

In harsh environments such as automobile chassis, outdoor robots, engineering equipment, etc., the protection performance of wire harnesses is especially critical.

What is a wire harness used for?

Wire Harnesses are used in a wide variety of electrical systems. From daily use of cars, automation equipment, to precision robots and medical instruments, almost all the devices that “need power + signal” can not be separated from the support of the wire harness.

As a professional wiring harness manufacturer, Linkwings has designed different types of wiring harness solutions for many OEMs, new energy enterprises and industrial control customers. Each industry has a different system structure and different usage environment, which puts forward different requirements on wiring methods, material selection, protection level and interface standard of wiring harnesses.

Below, we start from a few typical industries, one by one to analyze the specific application scenarios of wiring harness.

| Industry | Core Requirements | Typical Characteristics |

|---|---|---|

| Automotive / EV | High integration, safety protection, EMC | Compact layout, strict compliance |

| Industrial Automation | Modular design, easy maintenance, fast setup | Multiple control signals, clear labeling |

| Robotics / Machinery | High flexibility, long bend life, EMI shielding | Dynamic wiring, high-speed data lines |

| Medical Equipment | Miniaturization, chemical resistance, insulation safety | Hygiene standards, lightweight design |

| Construction Machinery | Harsh environment tolerance, vibration resistance, redundancy | Waterproof, dustproof, impact-resistant |

I. Automobile and new energy vehicle industry

Application Location:

- Main Harness: connecting ECU, power system, power distribution module.

- Power wiring harness: connecting battery, electric drive, electronic control (HV Harness)

- Branch wiring harness: door panels, lights, instrumentation, air conditioning and other modules are wired independently.

- High-voltage wiring harness: Specialized for new energy vehicles, the voltage is as high as 400V~800V, which requires very high insulation performance.

Industry characteristics:

- High temperature, high humidity, high vibration working conditions

- Compact space, complex wiring path

- High requirements for protection, anti-disconnection and EMC anti-interference.

In the design of BMS wiring harness for pure electric SUV, we adopt double shielding structure and precision plug design, passed the EMC test of the whole vehicle, and successfully support customers to complete the EU certification.

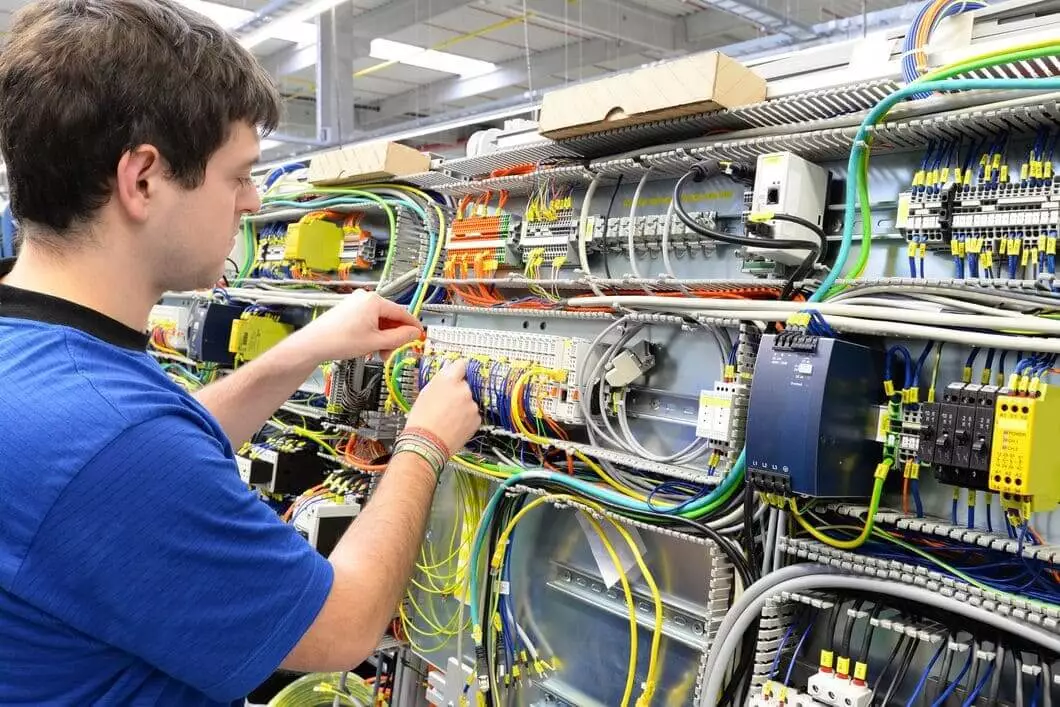

II. Industrial control equipment and automation systems

Application Location:

- PLC control cabinet wiring harness: connecting master control modules, IO modules, relays, terminal rows

- Production line equipment internal wiring: connect sensors, photoelectric switches, actuation solenoid valve

- Human-machine interaction panel: connecting touch screen, alarm light, switch button

Industry characteristics:

- Signal variety, complex interface types

- Requirements for clean wiring, fast assembly, easy maintenance

- Mostly use industrial grade snap-in connectors (e.g. M8/M12)

An electronics assembly plant was using traditional loose wiring that took hours to repair. We designed structured wiring harness modules for them, reducing assembly time by 50% and increasing maintenance efficiency by 3 times.

III. Intelligent robots and automated machinery and equipment

Application Location:

- Servo harness: connecting drives, motors, encoder feedback systems

- Drag chain wiring harness: used for repeated bending motion parts of the robotic arm

- Control bus harness: CAN/Modbus/Ethernet high-speed communication

Industry Characteristics:

- Long-time dynamic motion → high flexibility and high bending life required

- High precision requirements → Signal must be stable and anti-interference

- Compact dimensions → high integration in miniature wire harness/multi-core structure

We have designed a drag chain harness for an intelligent storage robot, using ultra-flexible TPE jacket material, passed 300,000 times U-bending test, and the system has been running stably for more than 2 years now.

IV. Medical equipment and precision electronic systems

Application Location:

- Hospital bed control system harnesses

- Medical cart/tester harnesses (ECG, ultrasound, etc.)

- Wiring harnesses for micro sensors and actuators

Industry Characteristics:

- Small size of the equipment → thin and compact wiring harness is required

- High safety → anti-short circuit, anti-static, anti-overheating

- Health norms → easy to clean the outer skin, sterilization resistance, no harmful gas release

A medical electronics customer had a wiring harness with insufficient resistance to cleaning agents, resulting in cracking of the outer skin and frequent failures. We switched to medical grade PVC wire and optimized the wrapping structure, and the equipment passed the whole set of IEC standard tests.

V. Construction Machinery and Special Vehicles

Application Location:

- Engine harnesses, control handle harnesses in excavators, cranes, agricultural machinery

- Power harnesses and lighting harnesses in mining trucks and special transportation vehicles.

Industry Characteristics:

- Extreme environment (high temperature, mud, water vapor, low temperature)

- Continuous vibration, shock, high frequency use

- High level of protection, IP67 or higher connectors are required

Special requirements for wire harnesses in different industries

Different devices, different environments and different functions have completely different requirements for wiring harnesses.

Behind a good wiring harness is a precise understanding of the use of the scene and engineering matching. The following is the “key special requirements” for wiring harnesses in different industries summarized by me in the field:

Automotive & New Energy Vehicles: High Integration + Anti-Interference + Safety Protection

- Compact wiring: Limited space available in the engine compartment and dashboard area requires a highly flexible wiring harness with a small bend radius.

- Strong EMC anti-interference ability: the entire vehicle has multiple controllers and communication buses (such as CAN, LIN), must use shielded wire or stranded wire design to reduce signal interference.

- High waterproof and fireproof requirements: engine compartment/chassis wiring harnesses are often exposed to rain, mud and sand, the plug must meet the IP67 rating, the wires need to be heat-resistant, flame-retardant

- Connector anti-wrong-insertion design: the fast pace of automotive production, the plug design must have anti-reverse insertion/anti-mixed insertion structure, to enhance assembly efficiency and safety.

Industrial control & automation lines: clear wiring + easy maintenance + long time operation

Industrial control equipment harnesses should be considered in advance of the alignment sequence, the direction of the line and maintenance logic. This can significantly improve the efficiency of the later project, especially after mass production troubleshooting efficiency.

- Clear labeling and color separation design: industrial control cabinets usually have dozens of control lines, the wire harness must have a clear label/color band, convenient for later maintenance and replacement.

- Quick plug structure: M8/M12 and other industrial quick-plug connectors are mostly used to realize quick assembly and quick module replacement.

- Long-term stability: the working environment has oil, dust, temperature rise, the wiring harness must be heat-resistant, corrosion-resistant, well insulated.

- EMI partition management: power lines, signal lines must be subregional wiring to avoid relays, high-frequency components on the communication caused by interference

Intelligent Robotics & Automation: Highly Flexible + Dynamic Service Life

In a set of logistics robot project, we upgraded the ordinary PVC wire to TPE super flexible wire, and adopted multi-core integrated wire harness structure. This solution reduced the wiring time of the whole machine from 2 hours to 35 minutes, and improved the stability of equipment operation and ease of use after the sale.

Special requirements:

- Highly Flexible Cable: Used for dynamic motion parts such as robotic arms and slides, wire harnesses need to have a bending life of more than 100,000 times.

- Harness miniaturization design: Robots usually have limited space and dense control modules, so the harness should be as thin and compact as possible.

- EMC anti-interference is more demanding: servo system, feedback line, sensor communication needs to be highly stable, it is recommended to use twisted shielded wire, special cable sheath.

- Reliable connectors: frequent plugging and unplugging of the harness requires connector life ≥ 500 times or more, the terminal needs to be equipped with automatic locking function.

Medical Equipment & Instrumentation: High cleanliness + high safety level

For medical projects, the wiring harness must be developed at an early stage in parallel with the structure of the device. This ensures that the wiring harnesses fulfill their function without disrupting the appearance and experience of the machine.

- Compliance with medical grade material standards: the wires need to comply with UL, REACH, ROHS and other environmental and biocompatibility requirements, and can not release harmful substances.

- Resistant to detergent/alcohol corrosion: Alcohol, hypochlorite and other detergents are commonly used in medical environments, so the outer jacket of the wire harness should be corrosion-resistant and not lose color.

- Miniaturized design: Portable medical equipment requires a lot of space for the wiring harness, which requires the use of wires under 0.2mm² + miniature terminals.

- High insulation level: to avoid the risk of electric shock, the connectors need to be insulated with an insulating cover or double insulation layer.

Construction Machinery & Outdoor Equipment: Extreme Weather Resistance + Redundant Reliability

Special requirements:

- Super protection level: operating in mud, sand, rain, snow, high temperature and high cold environment, the wiring harness needs to reach IP67~IP69K or even higher standard.

- Triple protection structure: Usually adopts inner core insulation + outer heat shrink tubing + corrugated tubing triple protection structure.

- Redundant wiring logic: It is recommended to design dual-channel (e.g., main + backup power supply) for critical control lines to enhance system fault tolerance.

- High-strength fixing method: Stainless steel clamps and double-layer strapping are required for wire harness installation to prevent vibration loosening.

Gaps in wire harness usage

As a wire and harness manufacturer, Linkwings has extensive experience in harness manufacturing and design. Therefore, we deeply realize that the “gap” brought by wiring harness is really very obvious.

I once took over an electric tricycle project. The customer started to use ordinary wires to weld the wires by himself, but the wires got hot, the insurance burned, the charging was unstable, and the whole vehicle had frequent problems. After we intervened and re-designed the wiring harness, we replaced it with the right wire diameter, standard connectors and modularized layout, not only did the failure rate drop dramatically, but the assembly and after-sales efficiency also increased several times.

There was another time when we were working on a robotic arm control system. In order to save some costs, the customer directly used ordinary signal lines to transmit servo feedback, and the result was that the controller always crashed. After troubleshooting, it was found to be EMC interference, we replaced the shielded twisted-pair cable and optimize the cabling structure, the equipment successfully passed the EMC test, stable operation until the end of the project.

In the industrial control industry is more common is a messy wiring problem. I have encountered a control cabinet wiring like a “spider web”. Maintenance engineers can only rely on memory to find the line, once the fault a few hours can not find the source. Later, we helped him design a structured wiring harness solution, numbering, prefabrication, modularization is very clear, maintenance time from two hours to half an hour, the customer is very satisfied.

All these projects make me more sure of one thing: the wiring harness is not the simpler the better, but the more reasonable the more trouble-saving. Well-designed, it is the tool that saves you time, money and trouble. Poor design, it is the first system problems, the most difficult to deal with the “hidden danger”.

Custom Wire Harnesses Solutions for You from Linkwings

In this article, we have introduced the question “What is a wire harness used for” from a number of perspectives. A wire harness is more than just a collection of cables, it is an indispensable neural network and energy pathway in every modern electrical system.

Whether in automobiles, industrial controls, robots or medical devices, wire harnesses are there to ensure accurate signals, stable power, structural clarity and equipment safety. Choosing a professional wiring harness solution is far more efficient and cost-effective than repair and rework after the fact.

Linkwings is a professional wiring harness manufacturer from China, focusing on providing high-quality, customized wiring harness solutions for automotive, robotics, industrial control, medical and other fields.

We offer:

✅ Small quantity ordering and fast prototyping

✅ One-on-one design and selection assistance from our team of engineers

✅ Full production in accordance with international standards such as IATF 16949, ISO, ROHS, etc.

✅ Rich export experience, support global customer cooperation

If you are looking for a reliable wiring harness partner, welcome to contact Linkwings, we understand the technology and the rhythm of project landing.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In