Home » Led Light Wire Harness

LED Light Wire Harness Manufacturer | Custom Led Wiring Harness Assemblies by Linkwings

Linkwings is a trusted LED light wire harness manufacturer offering custom wiring solutions for automotive lights, off-road LEDs, industrial lighting, and smart lighting systems. UL, ISO certified.

Custom Led Wire Harness from Led Light Wire Harness Manufacturer

Linkwings is a professional custom LED light wire harness manufacturer, with years of experience in harness development and services within the lighting industry. Our services cover a wide range of application areas, including automotive lighting, outdoor lighting, industrial lighting, and smart lighting. We are committed to providing customers with high-quality harness solutions that meet international certification standards (such as UL, RoHS, ISO 9001), tailored to meet diverse voltage, environmental, protection rating, and interface requirements.

Leveraging our automated production system and engineering-driven process capabilities, Linkwings offers a one-stop wiring harness service from structural design, material selection recommendations, sample prototyping to mass production delivery. We support multi-brand connector selection, waterproof structure integration, cable branch optimization, wire marking, and standardized packaging, helping customers enhance the connection reliability and production efficiency of their lighting systems. We are your trusted LED wiring harness partner.

Linkwings LED Light Wire Harness Collection

Linkwings offers a wide range of LED lighting harness products for various applications, including automotive lighting, off-road lighting, industrial lighting, smart control systems, and outdoor lighting projects. We support multiple harness structures, interface standards, and protection ratings. We can also provide fully customized development based on customer drawings, samples, or system requirements to meet the needs of different environments and electrical performance requirements.

Automotive LED Lighting Harness

- Used for headlights, daytime running lights, fog lights, taillights, turn signals, brake lights, etc..

- Supports waterproof connectors (such as AMP, KET), harness sleeves, and heat shrink tubing processes.

- Meets 12V/24V voltage system requirements and is resistant to vibration, high temperatures, and high humidity environments.

Application scenarios: Passenger vehicles, trucks, and special vehicle lighting systems

Off-road and Modified LED Light Harness

- Compatible with LED spotlights, work lights, strip lights, strobe lights, etc., supporting integrated relays and fuses;

- Compact structure and easy installation, suitable for multi-channel independent switch control;

- Supports universal plugs or custom connectors, and comes pre-installed with a waterproof protective housing.

Application scenarios: modified vehicles, ATVs, off-road vehicles, construction machinery

Industrial Lighting Harness

- Used in industrial lighting systems such as warehouse lights, high bay lights, track lights, and factory floodlights.

- Supports multi-branch structure, integrated power input and drive module connection.

- Features excellent heat resistance, anti-aging performance, and EMC compatibility.

Application scenarios: factory buildings, warehouses, production line LED lighting systems

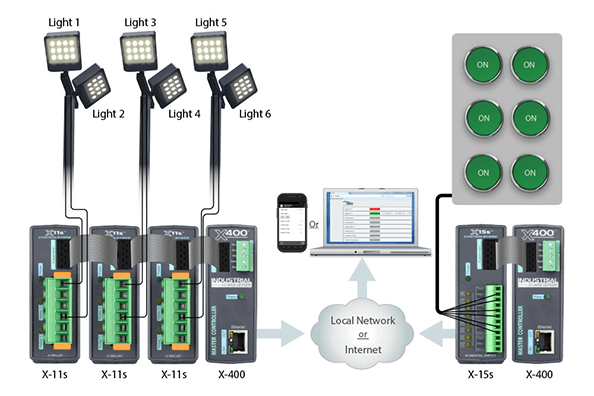

Smart Lighting Harness

- Compatible with smart lighting modules, supporting PWM/0-10V/DMX/RF/Bluetooth control signals;

- Can integrate control module power lines, signal lines, dimming module connectors, etc.;

- Supports custom communication port identification, shielded wire structure, and cable number labels.

Application scenarios: commercial space lighting, smart homes, smart city lighting control

Outdoor Waterproof Lighting Harness

- Suitable for outdoor lighting such as street lights, tunnel lights, landscape lights, and lawn lights;

- The connectors have an IP67/IP68 waterproof rating and are available with lockable connectors;

- They are UV-resistant, corrosion-resistant, and stable in low-temperature and humid environments.

Application scenarios: municipal lighting projects, landscape lighting fixtures, outdoor decorative lighting.

Custom LED Harness

- Support customization of multi-branch, multi-interface structures based on customer circuit diagrams or assembly drawings;

- Specify wire colors, wire lengths, heat shrink labels, shielding requirements, and cable types;

- Provide sample prototyping, bulk delivery, and installation guidance services.

Application scenarios: new product development, OEM project customization, complex structure lighting system wiring.

General Customization Parameters Supported:

| Parameter | Options/Details |

|---|---|

| Voltage Rating | 12V / 24V / 48V DC |

| Wire Gauge Range | 22 AWG – 12 AWG |

| Connector Brands | AMP, Deutsch, KET, JST, Molex, Custom Molded Connectors |

| Insulation Materials | PVC, XLPE, Silicone, TPE |

| Protection Rating | IP65 / IP67 / IP68 (depending on structure and connector type) |

Cases of LED Light Wire Harness

Linkwings’ LED lighting harness products are widely used in various industries, including automotive lighting, industrial lighting, outdoor lighting, smart lighting control, and portable lighting equipment. With extensive cross-industry service experience, we can customize specialized harness solutions that are structurally sound, stable in performance, and mature in craftsmanship, tailored to the electrical performance, installation environment, and protection rating requirements of different systems.

Case 1: United States – Custom LED Light Harness for Off-Road Vehicles

A California-based off-road vehicle modification brand sought to develop an integrated wiring harness for its 5-channel LED lighting system, incorporating relays, dual fuses, and waterproof connectors, capable of withstanding extreme conditions such as dust, high temperatures, and severe vibrations. The client emphasized the need for a compact harness design, reliable connectors, and high protection ratings.

Linkwings utilized Deutsch original connectors and high-flexibility XLPE cables to design a highly adaptable wiring harness structure featuring integrated heat shrink, branch sleeves, and waterproof encapsulation. The samples passed the customer’s vibration and environmental testing and were ultimately adopted on a large scale in the North American and Australian markets.

Case 2: Germany – Industrial Lighting Control Cable Assembly Optimization Project

A German industrial lighting manufacturer needed to customize a driver + dimming control harness for its high-bay lighting system, requiring compatibility with both power supply and PWM/0-10V control signals, excellent interference resistance, and improved factory assembly efficiency. The existing solution had complex wiring and a high rework rate.

Linkwings provided a three-in-one shielded wiring harness structure supporting multi-channel quick-connect interfaces and module interchangeability, utilizing UL-certified industrial cables, and optimized the wiring harness structure. The solution successfully helped the customer reduce wiring labor hours by over 30% and installation error rates.

Case 3: France – DMX Smart Lighting Control Cable Assembly Project

A French smart lighting integrator designed a DMX512-controlled lighting system for museums and exhibition halls. They urgently needed a cable module that could ensure signal stability while also facilitating quick on-site installation to address the challenges of tight project schedules and limited space.

Linkwings provided DMX wiring harnesses with terminal resistors, full numbering, and multiple branches, accompanied by high-density shielding structures and foolproof connectors, significantly reducing the customer’s manual wiring time. This solution has been successfully applied in multiple Paris municipal projects and has received consistent praise.

Case 4: Canada – Outdoor Lighting Waterproof Cable Assembly Project

A Canadian outdoor lighting engineering company needed to develop cold-resistant, waterproof, and highly reliable wiring harnesses for streetlights and ground-mounted lights used in winter environments with temperatures below -20°C. Traditional PVC wiring harnesses experienced issues such as cracking and water ingress at low temperatures, affecting project delivery.

Linkwings utilized low-temperature-resistant silicone cables, IP68 waterproof threaded connectors, and a heat-shrink + waterproof gasket sealing solution to ensure the harnesses could operate reliably in snow, ice, and rain environments. In the actual project, over 400 sets of harnesses operated flawlessly, earning the client’s long-term cooperation intent.

FAQs about LED Light Wire Harnesses

1. Does Linkwings support customization of LED cable assemblies based on customer drawings?

Yes, we support full customization based on customer drawings, samples, or functional specifications. Whether it’s a single lamp connection cable or a multi-channel integrated cable assembly, we can provide structural optimization recommendations and rapid prototyping services.

2. Can LED wire harnesses be integrated with relays, fuses, and control switches?

Yes. We can integrate relay modules, plug-in fuses, waterproof switches, and other components into the wire harness according to the functional requirements of the customer’s control system. This reduces wiring steps and improves assembly efficiency and safety.

3. What waterproof ratings do your LED cable assemblies support?

Our cable assemblies support IP65, IP67, or IP68 protection ratings depending on the application. We use waterproof connectors, waterproof sleeves, heat shrink packaging, and other techniques to ensure long-term reliable operation in outdoor, humid, or extreme environments.

4. Can LED cable harnesses operate stably in low-temperature, high-temperature, or outdoor environments?

Yes. We can choose low-temperature resistant silicone rubber wire, XLPE high-temperature resistant wire, UV-resistant sheathing, and IP68-rated connectors, which are suitable for working environments ranging from -40°C to 125°C. Therefore, they are widely used in outdoor lighting, automotive lighting, and other harsh conditions.