In modern automotive, home appliance, industrial equipment, and medical instrumentation systems, wire harnesses are virtually ubiquitous. So, what is a wire harness? It is a structured component that integrates multiple wires, cables, and connectors to facilitate the transmission of electrical signals or power. Compared to simple wiring methods, wire harnesses offer higher levels of systemization, maintainability, and interference resistance, making them an indispensable core connectivity solution in various complex devices.

This article will provide a professional analysis of what a wire harness is, its composition and functions, common application scenarios, and the differences between it and ordinary wires. Additionally, we will discuss how to identify high-quality wire harness products and why choosing a professional manufacturer like Linkwings is crucial for ensuring system performance. Whether you are an engineer, a procurement professional, or new to the electronics manufacturing field, this content will help you fully understand the value and principles of wire harnesses.

What is a Wire Harness?

A wire harness is an electrical connection system that organizes, binds, and protects multiple wires, cables, power lines, or signal lines according to specific electrical principles and spatial layouts. Its core purpose is to achieve stable, efficient, and compact power or signal transmission, thereby improving system wiring efficiency, reducing failure rates, and enhancing overall system reliability.

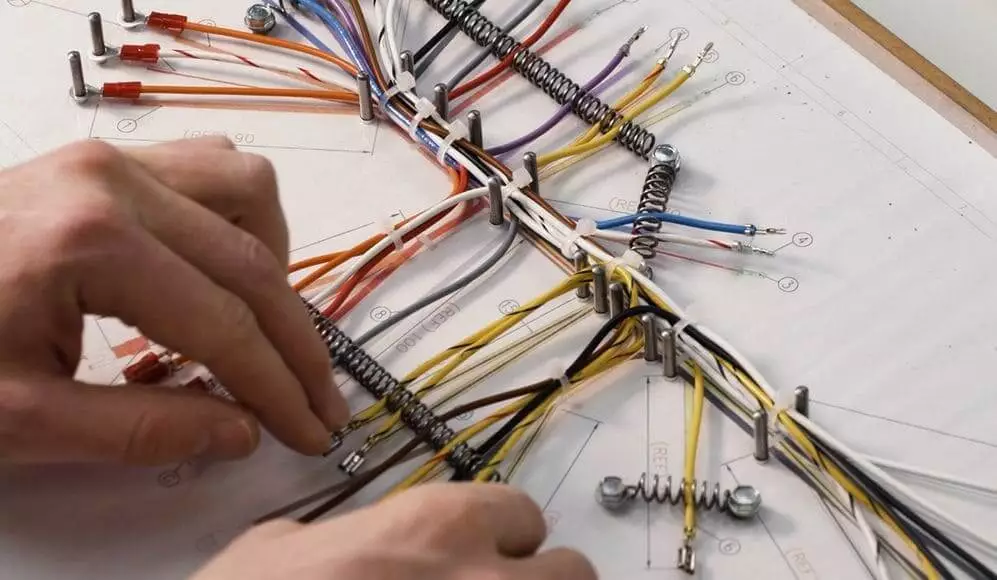

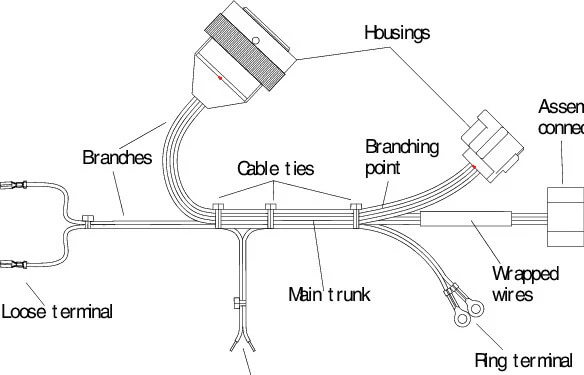

A typical wire harness typically consists of the following components: wires, connectors, terminals, insulating sleeves, tape or corrugated tubing, labels, and fasteners. These components are pre-assembled in the factory according to design specifications and are ready for plug-and-play installation when integrated into the system. This eliminates the need for complex on-site wiring, significantly improving assembly efficiency.

Unlike ordinary single wires, wire harnesses emphasize system integrity, reliability, and standardized manufacturing. They must not only meet basic electrical performance requirements but also possess excellent mechanical strength, wear resistance, fire resistance, and electromagnetic interference (EMI) protection capabilities. As a result, wire harnesses are widely used in industries with extremely high safety and stability requirements, such as automotive, aerospace, industrial control, home appliances, and medical equipment.

Basic Structure and Functions of Wiring Harnesses

A wire harness is a structured electrical connection system that is typically composed of multiple key components working together. Each component not only performs different electrical or structural functions, but also collectively determines the performance, lifespan, and reliability of the entire harness. Understanding its basic composition helps users better select and evaluate product quality.

Common components include:

- Wires/Cables: Used for power or signal transmission, typically single-core or multi-core copper conductors, with common specifications such as UL1007, AVSS, and TXL.

- Connectors: Electrical interfaces at the ends or intermediate points of the harness, used to connect to devices, modules, or circuit boards, with brands such as Molex, AMP, JST, and Deutsch.

- Terminals: Metal contact points connecting wires to connectors, available in crimped, soldered, or pierced types to ensure reliable conductivity.

- Sheathing and Insulation Materials: Such as PVC tubing, corrugated tubing, heat-shrink tubing, and tape, providing protection, thermal insulation, abrasion resistance, and waterproofing.

- Fastening and identification components: such as cable ties, positioning clips, labels, and heat-transfer printed numbers, used for positioning, grouping, and traceability management during installation.

The Primary Functions of Wiring Harnesses:

- Structured cabling: By bundling and encapsulating multiple wires according to circuit requirements, the overall wiring of the equipment becomes more organized. This enables faster installation and reduces assembly and maintenance costs.

- Enhanced connection reliability: Standardized crimping and plug-in structures effectively reduce the risk of loose connections and poor contact, improving the long-term operational stability of the entire system.

- Signal integrity protection: In high-speed transmission applications, the harness structure utilizes shielding layers, grounding arrangements, and twist spacing control to minimize EMI interference and signal attenuation.

- Enhanced environmental adaptability: By selecting materials resistant to high temperatures, oil, and water, the wiring harness maintains its electrical and structural performance even in harsh environments.

- Facilitated maintenance and traceability: A unified numbering and labeling system allows technicians to quickly locate fault points or replace components, improving operational efficiency.

Applications of Wire Harnesses

Wire harnesses, as core components of multi-wire integrated connection systems, are widely used in various electronic devices and systems that have high requirements for wiring system integrity, installation efficiency, and electrical reliability. Whether for power transmission, data communication, or control signal connection, wire harnesses play a crucial role as the “central nervous system.”

Automotive Industry

The automotive industry is one of the most widespread users of wiring harnesses. With the development of smart cars and electric vehicles, vehicles now integrate a large number of electronic control units (ECUs), sensors, cameras, and display modules, placing higher demands on electrical connection systems. A modern car typically contains over 3,000 meters of wiring, distributed across multiple subsystems, presenting stringent challenges in terms of wiring structure, space utilization, and reliability.

Wiring harnesses play a central role in transmitting power, electricity, and signals within vehicles. They are primarily used to connect engine management systems, body control modules, lighting, electric seats, air conditioning, and advanced driver-assistance systems (ADAS). Automotive wiring harnesses must possess excellent high-temperature resistance, oil resistance, vibration resistance, flame retardancy, and EMC shielding performance. As a result, they often utilize standard materials such as AVSS, FLRY, and GPT, and comply with automotive industry standards such as ISO 6722, LV 214, and IATF 16949.

Industrial Automation & Machinery

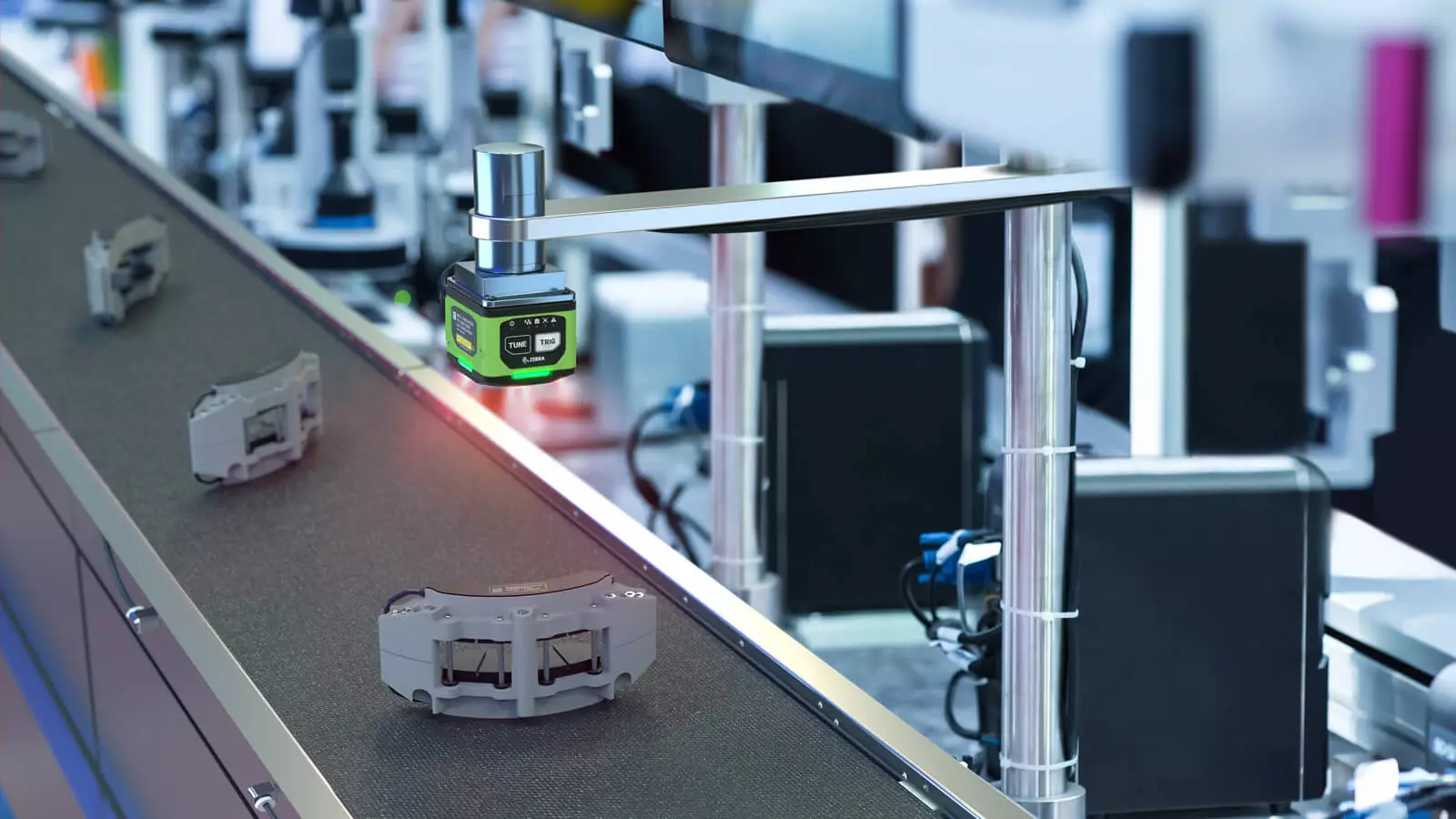

With the advancement of Industry 4.0 and smart manufacturing, various automated equipment, sensor networks, and control systems have placed clear demands on the modularity, maintainability, and electrical stability of wiring systems. Industrial applications often involve harsh environments such as dust, oil mist, high humidity, and high-voltage interference, which require higher durability and safety standards for connection harnesses.

Wire harnesses in industrial applications are primarily used to connect PLC controllers, sensors, servo drives, variable frequency drives, electrical control cabinets, relays, and I/O modules. They are used to achieve power distribution and control signal transmission. Linkwings offers industrial wiring harness solutions compliant with UL, CE, and IP67/IP68 protection ratings. These solutions feature anti-pullout, waterproof, and anti-misinsertion structures, making them suitable for high-frequency vibration and heavy-load applications such as robotic arms, conveyor lines, and CNC machine tools.

Medical Electronics and Diagnostic Equipment

Medical devices have extremely high requirements for the reliability, safety, and biocompatibility of connection harnesses. Common applications include portable ultrasound devices, endoscopes, vital signs monitoring, and medical imaging acquisition modules. These systems require high-speed, low-noise electrical connections in confined spaces, while supporting repeated plugging and unplugging and multiple disinfections.

Linkwings offers high-flexibility, multi-pair shielded differential cable harness solutions tailored for the medical field. The cables can be made from low-toxicity materials such as silicone, FEP, and TPE, meeting medical safety standards like ISO 10993 and IEC 60601. We also provide validated cable harnesses for medical device customers, featuring impedance control, electromagnetic interference (EMI) resistance, and bend resistance testing, ensuring stable long-term performance in critical diagnostic applications.

Consumer Electronics & Appliances

In home appliances, audio-visual equipment, and office automation products, wire harnesses serve as internal electrical connection bridges, playing a crucial role in enhancing overall assembly efficiency and optimizing structural layout. As consumer products evolve toward intelligence and miniaturization, wire harnesses are also transitioning toward smaller pitch, higher flexibility, and modular design.

Common applications include internal circuit connections in televisions, printers, coffee makers, microwave ovens, refrigerators, vacuum cleaners, and more. Linkwings offers a variety of small-sized flat cables (such as FPC/FFC), integrated switch terminals, magnetic connectors, and other wiring harness components. We also support bulk delivery and automated assembly. We strictly control crimping quality and insulation integrity to ensure safety and durability during long-term consumer use.

Artificial Intelligence and Edge Computing Devices

With the rapid growth of edge computing, AI camera systems, industrial vision modules, and other devices, high-speed interfaces such as LVDS, MIPI, and USB 3.0 have become the mainstream data transmission methods. These interfaces pose challenges in terms of impedance control, signal synchronization, and shielding structure design for cable assemblies. These devices are compact in size and have dense wiring, necessitating customized cable assemblies to ensure stable performance.

Linkwings offers high-speed differential cable assemblies and module-to-module connector cables, supporting ±0.5mm precision cable length, TDR impedance testing, twisted differential arrangement, and EMI grounding structures. We have developed specialized cable assemblies for edge AI gateways, smart image terminals, and other devices, and provide comprehensive technical documentation support (2D drawings, 3D STEP files, electrical performance test reports) to help customers accelerate product deployment.

The Difference Between Wire Harnesses and Ordinary Wires

In electronic device manufacturing and system integration, “wire harnesses” and “ordinary wires” are often confused, but the two have fundamental differences in structure, function, manufacturing processes, and application scenarios. Understanding these differences can help you make more professional choices in project design, procurement decisions, and product applications.

What are ordinary wires?

Ordinary wires typically refer to a single bare copper conductor or multiple strands of copper wire, combined with a simple insulation layer (such as PVC or PE) to form a wire product. They are used for basic power or signal transmission, such as a single-path connection from a power source to a load. While they can functionally “conduct electricity,” they lack structural protection, standardized interfaces, and signal management capabilities. They are primarily used for prototyping, low-complexity connections, or internal jumper wires.

| Comparison Aspect | Regular Wire | Wire Harness |

|---|---|---|

| Functionality | Basic current/signal transmission | Transmission + mechanical support + shielding + structured layout |

| Structural Complexity | Single or a few wires | Multiple wires + connectors + protective sleeves + mounting parts |

| Manufacturing Process | Cut and connect manually on-site | Pre-assembled in factory per schematic and BOM |

| Installation Efficiency | Labor-intensive, error-prone | Plug-and-play, fast and standardized installation |

| Signal Integrity | Susceptible to noise, inconsistent wire lengths | Supports shielding, twisting, impedance control for high-speed |

| Maintenance & Repair | Difficult to trace or replace | Clear labeling, modular replacement, easy diagnostics |

| Application Scenarios | Simple or internal electrical connections | Automotive, industrial, medical, aerospace, and complex systems |

| Compliance & Testing | Typically not tested individually | Fully tested: continuity, voltage, insulation, tensile strength |

Importance of Choosing a Professional Wire Harness Manufacturer

In the context of increasingly complex modern electronic systems and growing demands for reliability, selecting a professional wire harness manufacturer with engineering capabilities, quality systems, and industry experience has become a critical factor in project success. A wire harness is not merely a simple combination of wires; it involves multiple dimensions such as structural layout, electrical performance matching, connector compatibility, manufacturing precision, and testing standards. Any error in these areas could lead to system malfunctions, product recalls, or safety hazards.

Linkwings has over a decade of experience in wire harness research, development, and manufacturing, serving high-demand industries such as automotive, industrial, medical, and communications. We offer end-to-end capabilities, from design conversion, material verification, sample development, to mass production delivery. We strictly adhere to international standards such as ISO 9001, IATF 16949, and IPC/WHMA-A-620. All products undergo 100% testing before shipment to ensure that each wire harness delivers long-term stable, safe, and efficient connection performance, making us a reliable partner you can trust.

FAQs

Which devices or systems require wire harnesses?

Almost all medium-sized and large electronic systems require wire harnesses. These include automobiles, industrial robots, medical equipment, aviation systems, servers, home appliances, and more. Whenever there are multiple connections, signal control, or module distribution, structured wire harnesses are required to ensure reliable connections.

Can wire harnesses be customized according to project requirements?

Yes. Linkwings offers full-process customization services, including wire selection, interface matching, sheathing material, label numbering, shielding solutions, and more. We also provide complete solutions from sample production to bulk delivery, meeting various industry standards and certification requirements.

What tests are performed on a wire harness before it leaves the factory?

We perform 100% continuity testing, high-voltage withstand testing, terminal pull-out testing, and insulation performance verification on every wire harness. This ensures that the product complies with electrical safety standards and customer technical specifications, and is suitable for long-term stable operation.

Custom Wire Harnesses from Wire Harness Manufacturer

Through this in-depth analysis, we have gained a clear understanding of what is a wire harness. It plays a central role in modern electronic systems and differs significantly from ordinary wires in terms of structure, function, and reliability. Wire harnesses not only enhance system wiring efficiency but also ensure the long-term stable operation of equipment under complex conditions, making them an indispensable component in connection design.

As a professional wire harness manufacturer with years of industry experience, Linkwings is committed to providing global customers with high-quality wire harness solutions that meet industry standards and support customization. If you are seeking reliable, safe, and efficient connection products, please feel free to contact us for technical support and customized solution recommendations. We are your trusted connection partner.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In