What is Cable Harness Assembly? Ultimate Guide to Cable Harness Assembly

Home » What is Cable Harness Assembly? Ultimate Guide to Cable Harness Assembly

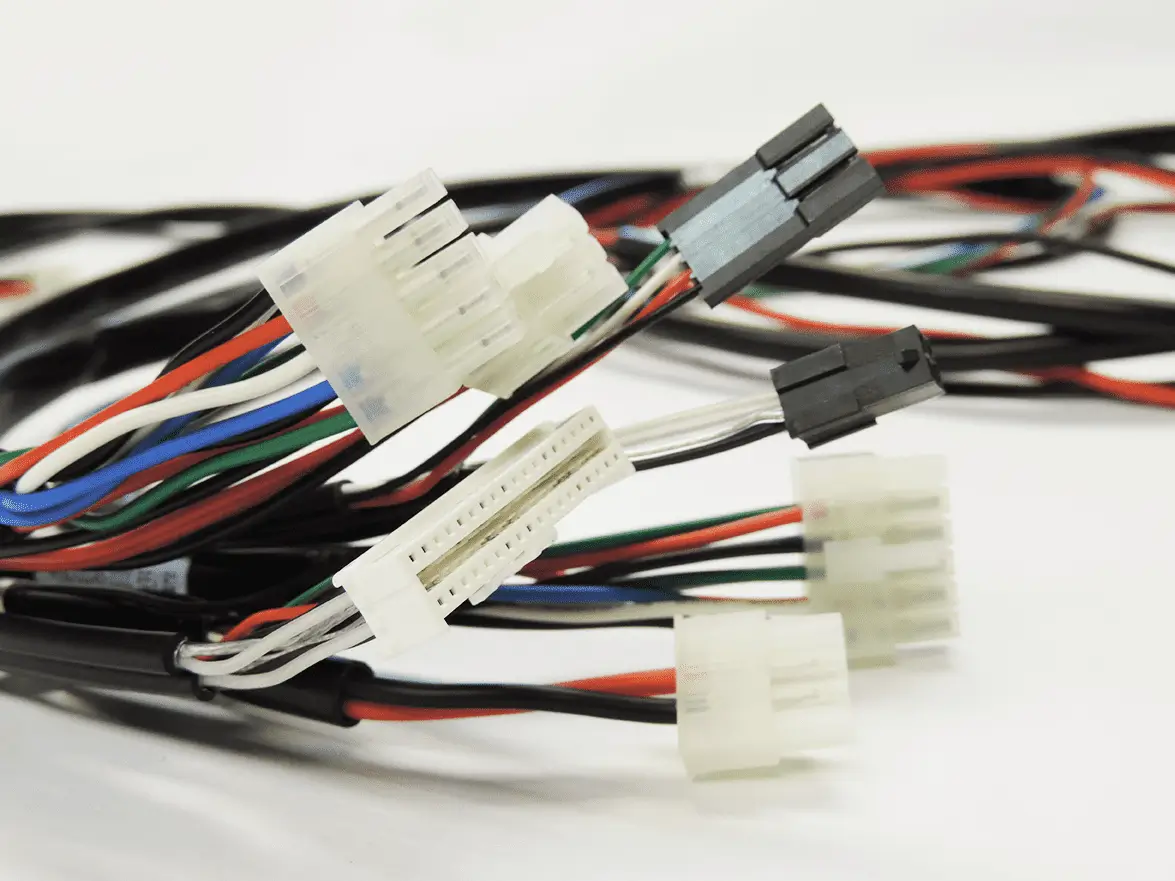

In modern electrical and electronic system design, a common question arises: What is a cable harness assembly? That is to say, what is a wire harness component and what is its function? A cable harness assembly is not merely a simple collection of wires. Through scientific design and standardized processes, it integrates multiple conductors, connectors, and protective components into a unified system to achieve reliable transmission and management of electrical power and signals. Widely used in automotive, industrial, medical, and aerospace sectors, it serves as a critical component for enhancing system reliability, safety, and production efficiency.

This article provides a comprehensive analysis of the definition, functions, applications, manufacturing processes, and design considerations of Cable Harness Assembly, helping you gain a deeper understanding of its value and practical applications.

What is a Cable Harness Assembly?

A Cable Harness Assembly is a complete electrical connection unit formed by assembling multiple wires through rational routing design and manufacturing processes, combined with connectors, sheaths, and protective components. It is not merely a simple “wire harness,” but a finished component that undergoes standardized design, manufacturing, and testing.

Compared to a basic cable harness, the Cable Harness Assembly emphasizes “componentization.” This means connectors and protective structures are pre-assembled at the factory, enabling direct use in equipment assembly. This approach reduces secondary processing, enhances consistency, and improves reliability.

Components of Cable Harness Assembly

A typical Cable Harness Assembly usually consists of the following parts:

- Wires/Conductors: Responsible for transmitting electrical power or signals, commonly made of copper or tinned copper.

- Insulation: Isolates conductors to ensure electrical safety, with common materials including PVC, XLPE, and PTFE.

- Connectors: Ensure reliable connection between the harness and equipment or modules.

- Sheath: Provides overall protection for the harness against friction, oil contamination, and chemical corrosion.

- Clamps/Ties: Secure wiring to maintain a neat and robust structure.

Core Function of Cable Harness Assembly

The primary role of a Cable Harness Assembly is to centralize the management, protection, and connection of electrical power and signals. It:

- Integrates complex electrical wiring into modular components, simplifying internal device cabling.

- Provides protective functions to prevent electrical failures caused by vibration, friction, or environmental factors.

- Ensures connection reliability and consistency, enhancing long-term device stability and maintenance efficiency.

Primary Functions of Cable Harness Assembly

A Cable Harness Assembly is not merely a bundle of wires; it is an engineered and standardized electrical connection module. Its core functions are reflected in the following aspects:

1. Efficient Transmission of Electrical Power and Signals

Through optimal wire gauge selection, twisted-pair or shielded designs, the Cable Harness Assembly ensures stable transmission of current and signals while minimizing voltage drop, crosstalk, and electromagnetic interference (EMI). This is particularly critical for applications requiring high-precision signals, such as medical imaging, automotive ADAS, and industrial automation.

2. Safety Protection

The harness assembly provides insulation, protection, and secure fixation for conductors, effectively preventing short circuits, leakage currents, and overheating. The use of jackets, corrugated tubing, and heat-shrink sleeves mitigates mechanical wear, vibration fatigue, and environmental corrosion.

3. Structural Optimization and Space Management

By integrating multiple wires into a modular assembly, cable harness assemblies reduce messy wiring, optimize space utilization, and create tidier internal equipment wiring. This not only enhances assembly efficiency but also facilitates future maintenance and rapid replacement.

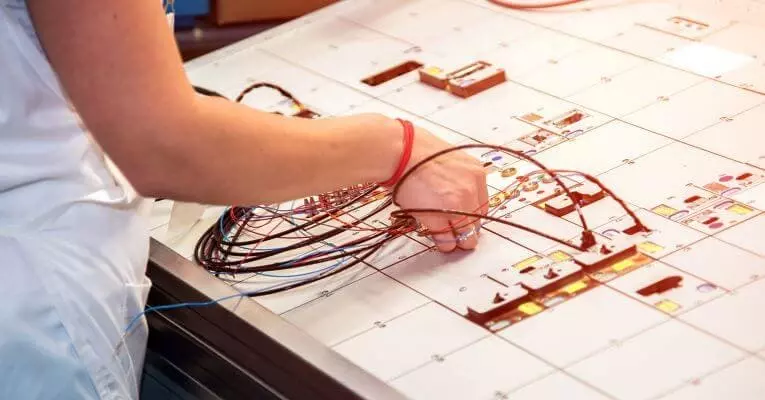

4. Enhanced Production and Maintenance Efficiency

Standardized cable harness assemblies enable plug-and-play functionality on assembly lines. This effectively eliminates errors caused by manual wiring and shortens production cycles. The modular structure also allows for complete replacement during maintenance, minimizing downtime.

5. Strengthening System Reliability

Through unified manufacturing processes and rigorous testing (such as continuity testing, withstand voltage testing, and vibration testing), Cable Harness Assemblies maintain long-term reliability in harsh environments. This is critical for industries including automotive, aerospace, and medical.

Applications of Cable Harness Assembly

Cable Harness Assembly is integral to nearly all complex systems requiring electrical connections. Its core value across different sectors can be summarized as follows:

- Automotive → Safety and System Integration

- Industrial → Stability and Durability

- Consumer Electronics → Lightweight and Efficiency

- Medical → Precision and Reliability

- Aerospace → Lightweight and Extreme Environment Adaptability

1. Automotive Industry

- Application Scenarios: Engine wiring harnesses, body control systems, lighting systems, ADAS (Advanced Driver Assistance Systems), infotainment and information systems.

- Characteristics and Requirements: Must comply with automotive standards (ISO 6722, IATF 16949), featuring high-temperature resistance, vibration resistance, waterproofing and dustproofing (IP67/68), while supporting high-current power delivery and high-speed signal transmission.

- Value: Equivalent to the “neural network of the vehicle,” determining the electrical stability and safety of the entire vehicle.

2. Industrial Automation & Equipment

- Application Scenarios: PLC control cabinets, robots, CNC machine tools, production line sensors and drive systems.

- Characteristics & Requirements: Harnesses must exhibit high durability and interference resistance, withstand complex environments like vibration, oil contamination, and dust, typically requiring shielded structures and flame-retardant jackets.

- Value: Enhances equipment operational stability and production line reliability while reducing maintenance downtime.

3. Consumer Electronics

- Applications: Printers, computers, copiers, televisions, smart appliances, gaming consoles.

- Characteristics: Emphasis on lightweight design and space optimization, requiring modularity, cost control, and mass production efficiency.

- Value: Accelerates assembly speed and consistency while ensuring compact size and aesthetic appeal.

4. Medical Devices

- Application Scenarios: CT/MRI imaging systems, ultrasound diagnostic devices, patient monitoring systems, laboratory analytical instruments.

- Characteristics: Demands stringent signal integrity and electrical safety compliance with medical standards like IEC 60601; reliable insulation and shielding to prevent noise interference affecting diagnostic accuracy.

- Value: Ensures high-precision transmission of medical data and imaging, safeguarding patient safety.

5. Aerospace

- Application Scenarios: Aircraft cockpit instruments, flight control systems, navigation and communication equipment, satellite electrical systems.

- Characteristics and Requirements: Lightweight, high-temperature resistance, vibration resistance; compliance with stringent standards like AS9100 and MIL-SPEC; typically utilizes high-performance materials (e.g., PTFE, silicone rubber insulation).

- Value: Maintains long-term stable operation in extreme environments, safeguarding flight and mission safety.

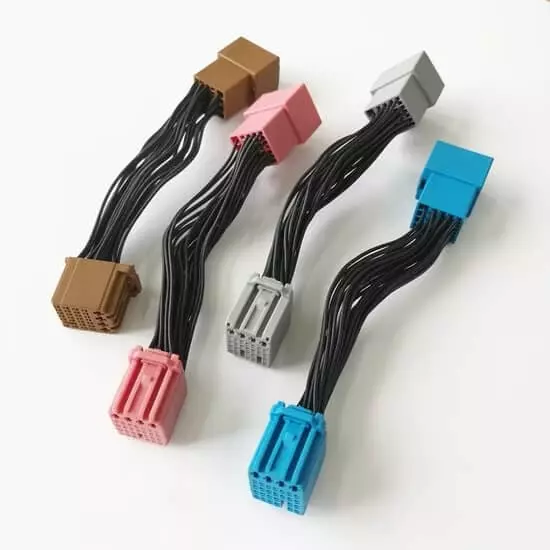

Types of Cable harness Assembly

| Type | Key Features | Typical Applications |

|---|---|---|

| Power Harness Assembly | Large cross-section conductors, high-temp resistant, flame-retardant, strong current capacity | Automotive engine power, EV high-voltage systems, industrial power distribution |

| Signal Harness Assembly | Thin wires, twisted pair/shielded design, ensures signal integrity and EMI resistance | Medical equipment, industrial sensors, consumer electronics |

| Hybrid Harness Assembly | Combines power and signal wires, requires partitioning/shielding to avoid interference | EV battery management systems (BMS), robotics, communication devices |

| Custom Harness Assembly | Highly customized, supports special materials and connectors, designed for extreme environments | Aerospace, military, medical diagnostic equipment, industrial automation |

- Definition: A harness assembly specifically designed for electrical power transmission.

- Features: Features large-cross-section conductors, high-temperature resistance, flame retardancy, and strong current-carrying capacity.

- Applications: Automotive engine power supply, electric vehicle high-voltage systems, industrial power distribution.

2. Signal Harness Assembly

- Definition: A wiring harness assembly for low-voltage or high-speed signal transmission.

- Features: Fine-gauge wires, often employing twisted-pair or shielded structures to ensure signal integrity and anti-interference performance.

- Applications: Medical imaging equipment, industrial sensor networks, consumer electronics.

3. Hybrid Harness Assembly

- Definition: Integrated assembly combining power and signal lines within a single harness.

- Features: Complex structure requiring optimized routing and shielding design to prevent power-signal interference.

- Applications: Battery Management Systems (BMS) in new energy vehicles, intelligent robots, communication equipment.

- Definition: Non-standard harness assemblies designed and manufactured to meet specific customer requirements.

- Features: Highly customized, supporting diverse conductor materials (e.g., tinned copper, silver-plated copper), insulation jackets, and specialized connectors for extreme environments.

- Applications: Aerospace, defense, medical diagnostic equipment, industrial automation production lines.

Key Design Considerations for Cable Harness Assembly

- Space and Routing Paths: Plan routing rationally to avoid excessive bends and crossings, enhancing assembly and maintenance efficiency.

- Current and Insulation Rating: Select appropriate conductors and insulation materials based on operating voltage and current to ensure safety and reliability.

- Environmental Factors: Consider temperature, humidity, vibration, and chemical corrosion when choosing suitable jackets and protective components.

- EMI/EMC Suppression: Reduce electromagnetic interference through twisted pairs, shielding, and grounding designs to guarantee signal integrity.

- Standards and Certifications: Adhere to standards such as IPC/WHMA-A-620, UL, and IATF 16949 to ensure compliance and quality.

Although both Cable Harness Assembly and Cable Assembly are electrical connection products, their design philosophies and application scenarios differ:

- Cable Harness Assembly emphasizes internal wiring management within systems, integrating and protecting multiple wires. It is suitable for internal connections in complex equipment.

- Cable Assembly focuses more on point-to-point connections, typically consisting of a single cable or a small number of cables paired with connectors. It is used for interfacing between modules or devices.

| Aspect | Cable Harness Assembly | Cable Assembly |

|---|---|---|

| Definition | Multiple wires organized as a modular wiring system | One or more cables with connectors as a finished product |

| Key Function | Internal wiring, space optimization, protection | Point-to-point connection between modules or devices |

| Applications | Automotive, control cabinets, medical, aerospace internal wiring | Power cords, jumpers, Ethernet cables, extensions |

| Flexibility | Highly customized, designed for complex environments | More standardized, suitable for common interfaces |

| Standards | IPC/WHMA-A-620, IATF 16949, AS9100 | UL, IEC, RoHS, CE |

FAQs

Q1: Can Cable Harness Assemblies be customized?

A1: Yes. Custom designs can be implemented for conductors, insulation, jackets, shielding methods, and connectors based on different applications (automotive, industrial, medical, aerospace).

Q2: How long does it take to produce a Cable Harness Assembly?

A2: It depends on complexity. Simple standard assemblies may be completed in days, while complex custom wire harnesses (e.g., for new energy vehicles or medical devices) may require several weeks.

Q3: What standards do Cable Harness Assemblies comply with?

A3: Common standards include IPC/WHMA-A-620 (wire harness assembly), UL/CSA (electrical safety), IATF 16949 (automotive), AS9100 (aerospace), etc., depending on the industry application.

Conclusion

In summary, cable harness assemblies are critical components in modern electrical and electronic systems. They not only enable efficient transmission of electrical power and signals but also enhance safety, reliability, and assembly efficiency through rational design and standardized manufacturing.

Whether in automotive, industrial, medical, or aerospace applications, cable harness assemblies serve as the “nervous system” ensuring long-term stable operation of equipment.

As a professional supplier, Linkwings delivers standardized and customized Cable Harness Assembly solutions compliant with international standards. From design to mass production, Linkwings provides reliable support and sustained value for our clients’ projects.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In