Our automotive wiring harness manufacturing process

Learn More About Linkwings Automotive Wiring Harness Manufacturing Process.

What Is Automotive Wiring Harness Manufacturing and Why Does It Matter?

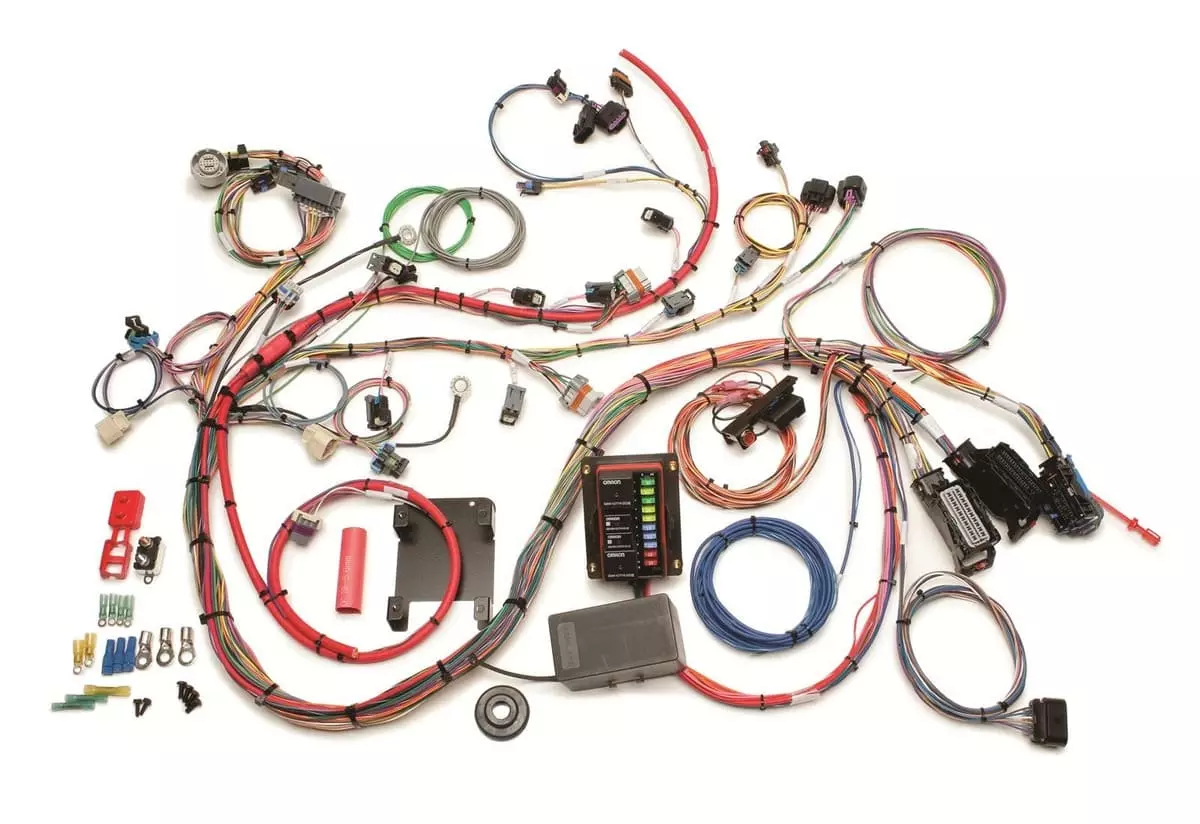

Automotive wiring harness manufacturing refers to the wire, cable, terminals, connectors, insulation materials and other components, in accordance with the vehicle electrical system design drawings, through the cutting, crimping, assembly, insulation protection, functional testing and other processes, systematic construction of a complete, can be installed into a complete cable assembly process. It is an indispensable link in the construction of automotive electronic systems, known as the “automotive nervous system” of the core support structure.

A modern automobile usually contains as many as 500 to 3,000 wires and hundreds of connectors. Used to connect the engine control unit, sensors, lighting systems, in-car entertainment, air conditioning, airbags, charging modules, drive motors and other functional modules. Therefore, the quality and stability of wiring harness manufacturing directly determines the safety, functional stability and user experience of the entire vehicle.

In today’s rapid advancement of intelligence and electrification, automotive wiring harnesses not only carry power transmission tasks, but also undertake more and more high-speed data communication and system control functions. For example: Ethernet cable for ADAS system, high voltage power cable for EV platform, data cable for on-board camera, etc., all of which require wiring harnesses with high consistency, high precision processing and zero error assembly capability.

Therefore, wiring harness manufacturing is not simply “wiring”, it is a professional engineering system that integrates precision process control, quality system, digital design, automation equipment and standardized testing. In the field of high-end automobile manufacturing, the failure of any wiring harness may lead to abnormalities in the entire vehicle system and even cause safety accidents. For OEMs, Tier 1, custom tuners or exporters, choosing a wiring harness manufacturer with standardized manufacturing capabilities and process controllability is a key step to guarantee project success and brand reliability.

Automotive Wiring Harness Manufacturing Process

The manufacturing of automotive wiring harnesses is a highly systematic engineering process. It involves multiple processes and requires precision and standardization at every step. In high-volume OEM production and customized projects, the wiring harness manufacturing process is not only an assembly process, but also a set of rigorous system to ensure product safety, electrical performance, installation compatibility and traceability.

- Design Harness

- Raw Material Purchase

- Wire Preparation

- Assembly & Insulation

- Electrical & Functional Testing

- Final QC & Delivery

Learn Linkwings Automotive Wiring Harness Manufacturing Process

Linkwings’ six processes for producing automotive wiring harnesses not only reflect the standardization, refinement and flow characteristics of wiring harness manufacturing, but also represent a complete closed loop from “design engineering → manufacturing execution → quality delivery”. It ensures that every wiring harness can be delivered to customers on a safe, accurate and traceable basis.

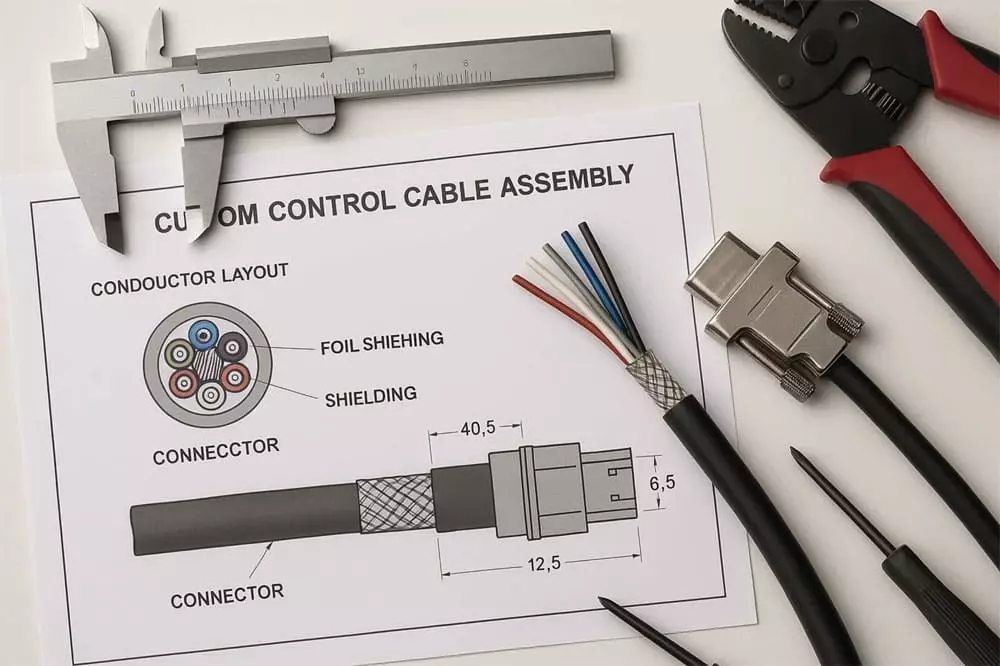

Process 1: Design Automotive Wiring Harness

It all starts with the design. Before manufacturing, our engineers will draw wiring harness diagrams, unfolding diagrams, and connector definition diagrams through professional CAD software based on information such as the electrical architecture of the entire vehicle, the arrangement of the electronic control unit (ECU), and the requirements of functional modules.

At the same time, the engineering BOM (wires, terminals, jackets, heat-shrinkable tubes, etc.) and process schedules are also generated simultaneously as the basis for production execution.

The design phase determines the performance, safety, assemblability and maintenance efficiency of the entire wiring harness, and is the “brain” of the entire manufacturing system.

Process 2: Automotive Wiring Harness Raw Materials

Based on the BOM list generated from the design drawings, Linkwings’ purchasing department prepares materials to match the project: wires (by gauge, color, and material), connectors (AMP, Deutsch, Yazaki, etc.), terminals, heat-shrink tubing, bellows, ties, labels, and more.

All raw materials must pass incoming inspections, including wire resistivity, terminal size, connector fit, temperature resistance rating, etc. Linkwings’ car wire harnesses aim to far exceed industry standards such as SAE, ISO, IATF, etc. The quality of materials is directly related to the performance stability and life reliability of the finished wire harness.

Process 3: Wire Preparation of car wiring harness manufacturing

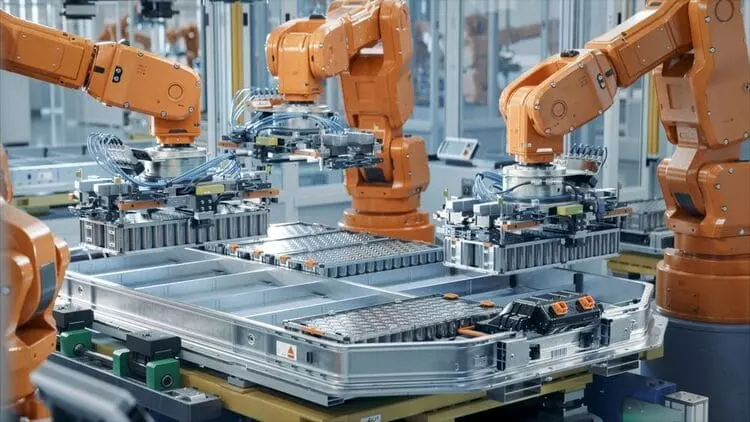

This is the first step in the physical processing of the wiring harness.Linkwings production of car wiring harnesses is done by automated equipment. This includes: precise wire cutting (according to the length of the drawing), stripping of the ends (reserving the crimp area), printing of the wire number (thermal transfer or inkjet), and pre-positioning of the terminals, etc. This stage requires high precision and consistency in order to avoid “length errors, copper wire errors, and copper wire errors”.

The requirements for this stage are high precision and consistency. During the manufacturing process, we try to avoid problems such as “length errors, copper wire damage, and misprinting”. Some complex models are also cut in batches to support modular assembly.

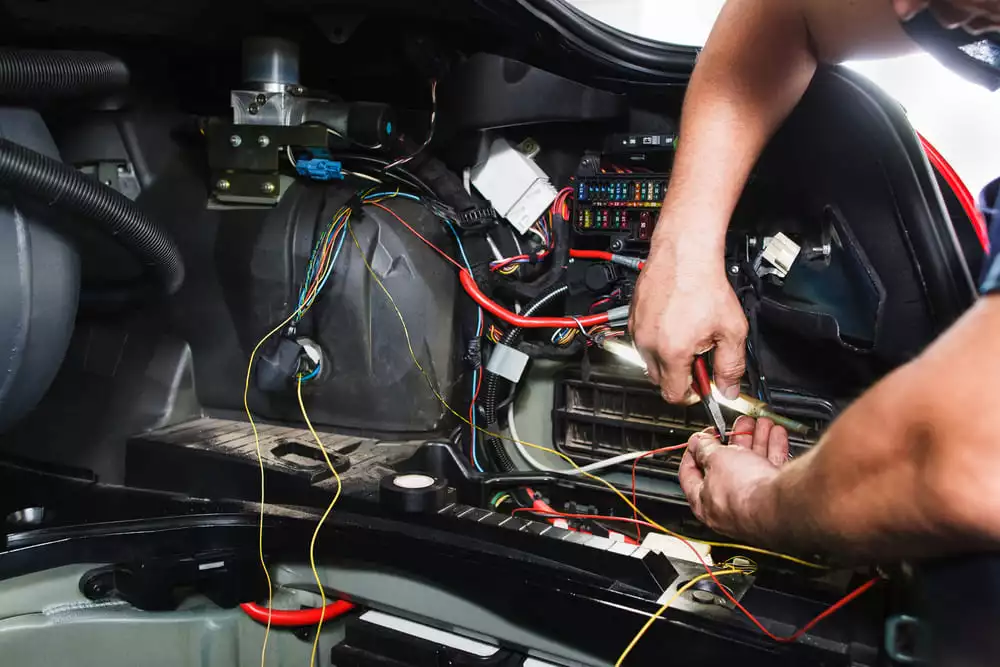

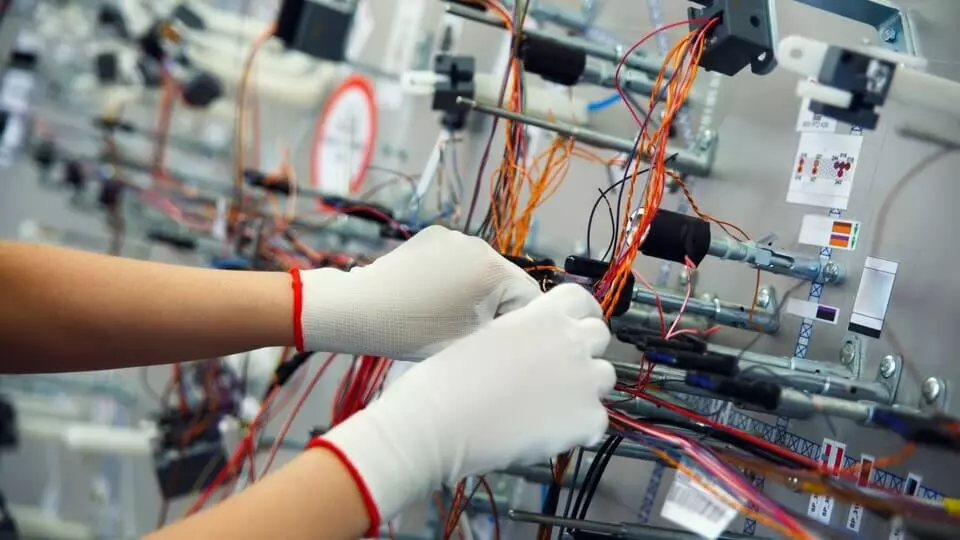

Process 4: Assembly & Insulation of automotive wiring harness manufacturing

This is the core part of wire harness manufacturing. On the Layout Board, our operators follow drawings for wire routing, branching, crimping terminals, plugging connectors, installing jackets/bellows, and taping.

Additional processing such as shrinking heat shrink tubing, waterproof sealing, and cloth tape wrapping are also required at key stations. Modularized sub-harnesses (e.g. camera wires, ambient light wires, radar wires) are often introduced into high-end models or intelligent systems and combined with the main trunk to enhance assembly efficiency and service and maintenance convenience.

Process 5: Electrical & Functional Testing of automotive wiring harness manufacturing

All wiring harnesses you obtain from Linkwings must pass 100% electrical function testing after assembly.

Our quality control department uses a harness test rig to perform full channel testing for shorts, breaks, mismatches, conductivity, voltage withstand, and more. High-voltage withstand breakdown tests or signal interference tests are also conducted when necessary. In addition, for safety purposes, our engineers conduct simulated load tests on critical systems (such as power control harnesses and high-voltage harnesses) to ensure that there is no abnormal heat buildup, voltage drop or signal loss when the harnesses are energized for operation.

Process 6: Final QC & Delivery of automotive wiring harness manufacturing

The finalized wire harnesses are also subject to manual appearance inspection, size review, label proofreading, packaging verification and other procedures to ensure that the delivery status is in full compliance with customer specifications.

Each harness is labeled with a barcode traceability label and packaged according to the model, module, and region. Before shipment, the Quality Department generates inspection reports, drawing signature documents and other certificates of compliance according to customer requirements to support the customer’s subsequent assembly line for quick identification and installation.