Home » Battery Wire Harness Manufacturer

Battery Wire Harness Manufacturer – Custom Solutions by Linkwings

Linkwings is a professional battery harness manufacturer. We have extensive experience serving customers in electric vehicles, energy storage systems, lithium battery assembly, and industrial equipment. We also support fully customized production and international certification.

Battery Wire Harness Series

In battery system applications, different scenarios have their own technical requirements for wire harness performance, structure, and connection methods. As a professional battery wire harness manufacturer, Linkwings provides a variety of customized wire harness solutions for different application areas. These include low-voltage signal transmission, high-voltage main power connections, multi-branch power supply, and precise matching with BMS systems. The following are the six major categories of battery wire harness products that we regularly support.

EV Battery Wire Harness

- Main power harness, BMS signal lines, temperature sensor lines, etc. for EV battery packs.

- Supports high voltage (600V/1000V), fireproof and flame retardant, UL cables.

- Connectors available: TE, APTIV, Yazaki, KET, and other automotive-grade series.

Energy Storage Harness

- Designed specifically for residential/commercial/industrial energy storage systems, such as wall-mounted batteries and energy storage cabinets.

- Supports multi-channel output, integrated CAN communication lines, and comes with waterproof identification labels.

- Compatible with inverters, battery management systems (BMS), DC circuit breakers, and other interfaces.

Lithium Battery Pack Harness

- For small lithium battery modules, such as handheld tools, electric scooters, drones, etc.

- Compact harness structure, supports multi-pin micro connectors and fine wire crimping

- Supports terminal potting, heat shrink protection, connector coding and marking

High Current Battery Cables

- Suitable for high current output interfaces, such as busbar connection cables, copper busbar connection cables, and terminal jumper cables.

- Flexible silicone cables or TPE cables can be used, supporting temperature rise control and custom colors.

- Cable ends can be fitted with crimped copper lugs + heat shrink tubing + laser marking identification.

Battery Connector Harness

- On-demand configuration of battery connectors from brands such as Anderson, Molex, Amphenol, TE, etc.

- Used for modular connections between batteries and inverters, charging stations, battery replacement systems, etc.

- Provides standard connection module prototyping and anti-misinsertion design support.

Custom Multi-branch Harness

- Integrate multiple output/signal groups into one unit to reduce customer wiring complexity

- Supports multiple cable lengths, branch distances, color-coded cables, and integrated protective structure

- Compatible with wiring diagrams and 3D models to support structural design

Why Choose Linkwings as your battery wire harness solutions supplier?

As a company specializing in battery harness manufacturing, Linkwings leverages its stable manufacturing capabilities, rigorous quality system, and extensive industry service experience to provide customers with highly reliable, consistent, and efficient harness solutions.

Focusing on customized battery harness design

Linkwings specializes in providing full-process customized harness solutions based on customer drawings and requirements. Whether it is the interface, wire length, or branch structure, everything can be precisely matched to the project.

Complete set of automated processing equipment and precision process control

We have introduced fully automated wire stripping and crimping equipment to ensure that each wire harness is dimensionally accurate and crimped consistently. Through a digital process management system, we achieve full traceability throughout the entire process.

Multi-brand connectors and cables with strong compatibility

Supports mainstream connectors such as Molex, TE, Anderson, and UL/TÜV certified cables. Ensures product compatibility with global markets and reduces system integration risks.

Meets the requirements of high-voltage/high-current battery system applications

The wiring harness supports high-voltage applications up to 1000V and high-current applications exceeding 200A, utilizing high-flexibility insulating materials and large-cross-section copper wires. It meets the high-performance requirements of power batteries and energy storage systems.

Strict quality control standards and multiple factory tests

Each wire harness undergoes continuity testing, insulation testing, and tensile testing in accordance with the ISO 9001 quality system. We support customer-defined testing items to ensure delivery compliance.

Rapid response and efficient delivery capabilities

Samples can be delivered in as little as three days, with mass production stable at 7–15 business days. Dedicated project technical support is provided to help customers shorten product development cycles.

Manufacturing and Quality Capabilities

Linkwings possesses the capability to manufacture battery harnesses in large volumes with high consistency. We strictly adhere to the ISO 9001 quality management system for quality control, ensuring that each harness meets high-precision standards in terms of dimensions, crimping, insulation, and structural identification.

All products undergo rigorous testing, including continuity, high-voltage insulation, tensile strength, and appearance inspections. With a stable delivery schedule and flexible project response mechanisms, Linkwings has become a trusted harness manufacturing partner for numerous battery system customers worldwide.

Applications of Battery Wire Harness

Linkwings’ battery wire harnesses are widely used in multiple key industries and system platforms, covering areas such as new energy, electric transportation, energy storage systems, and industrial equipment. We not only provide customers with high-quality products, but also engage in technical collaboration, deeply participating in their product development and system integration. This ensures that our harness solutions are truly tailored to the application environment and performance requirements.

Electric Vehicle Battery Systems (EV Battery Packs)

- High-voltage cables, low-voltage signal cables, and temperature-sensing cables for power battery packs in new energy vehicles;

- Meets the stringent environmental requirements of high vibration, high temperature, and high voltage;

- Has served multiple new energy vehicle manufacturers, modification plants, and battery pack contract manufacturers.

Representative applications: passenger vehicle power battery packs, commercial electric trucks, and electric buses.

Residential & Commercial Energy Storage Systems (ESS)

- Applicable to wall-mounted energy storage, battery cabinets, container energy storage, and other scenarios;

- Supports high-power charging/discharging interfaces and BMS data line integration;

- Branch line length and numbering can be customized according to the customer’s electrical wiring plan.

Representative applications: 5kWh to 200kWh residential energy storage cabinets, residential photovoltaic-storage integrated systems, and commercial and industrial energy storage power stations.

Lithium Battery Module Assembly

- Assembly of lithium battery modules for handheld devices, small robots, drones, electric skateboards, and other devices;

- Supports small connectors, precision signal lines, and compact wiring harness customization;

- Provides flexible layout and plug-in interface optimization services.

Representative applications: lithium battery packs for scooters, handheld tool modules, and consumer lithium battery connection cables

Industrial Equipment & Robotics

- Battery harnesses are widely used in AGV carts, logistics robots, unmanned forklifts, etc.

- Supports high-current power supply lines, high-flexibility wires, and connector anti-disengagement locking designs.

- Balances cable routing space optimization and tensile strength.

Representative applications: AGV/AMR vehicles, warehouse logistics robots, automatic handling equipment

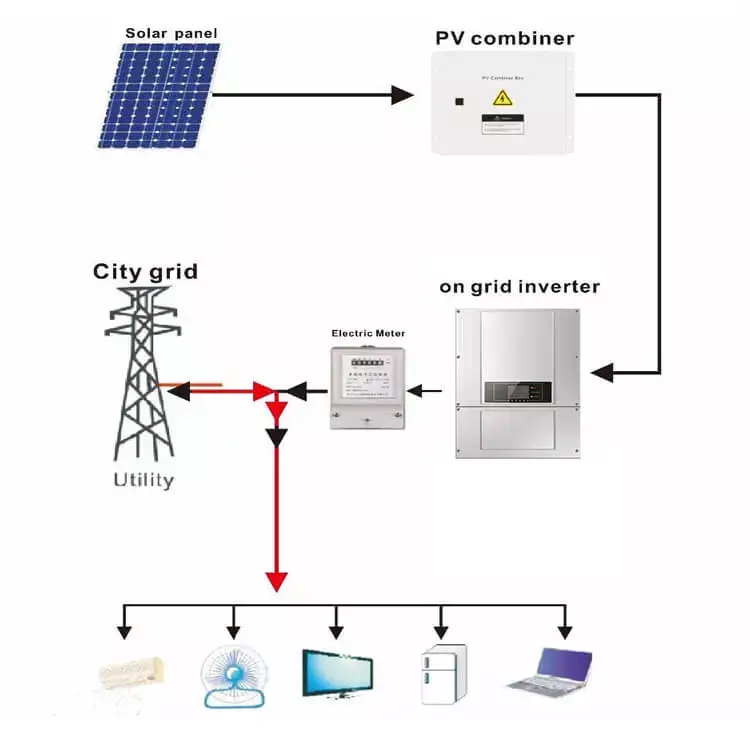

Photovoltaic + Energy Storage Hybrid Systems (PV + Battery Hybrid Systems)

- Used for connecting battery packs to inverters/controllers in photovoltaic-storage hybrid systems;

- Compatible with DC connectors such as MC4, XT60, and Anderson;

- Supports integrated design of cable harnesses and solar cables.

Typical applications: residential photovoltaic-storage power stations, portable energy storage power supplies, off-grid systems.

Test Fixtures and Pack Harness Development and Verification (Battery Testing & Lab Prototypes)

- Engineered sample lines or test harnesses specifically designed for battery laboratories, test centers, and BMS manufacturers;

- Supports pluggable structures, quick-change interfaces, and high-temperature-resistant test line designs;

- Compatible with port adapter boards, numbered labels, and fixture harnesses.

Representative applications: battery BMS test platforms, pack sample prototyping, and test cabinet wiring.

FAQs about Linkwings Battery Wire Harnesses

1. Can you customize battery harnesses based on customer drawings?

Yes, Linkwings offers fully customized services, supporting the design of harness solutions based on customer-provided BOMs, battery structure diagrams, or connection diagrams. We can assist in optimizing interface selection, wire length, branch locations, and numbering during the customization process to ensure a compact structure, easy installation, and stable performance.

2. What is the maximum current and voltage supported by the battery harness?

Our harness products support a maximum voltage of 1000V DC and a current of over 200A. For high-power applications, we use large-cross-section multi-strand copper wires (such as 2 AWG) with high-temperature silicone or TPE insulation materials to ensure transmission efficiency and temperature rise control.

3. Can specific brands of connectors and cables be selected?

Yes. We are compatible with a variety of internationally recognized brands of connectors (such as Anderson, Molex, TE, Amphenol, etc.) and certified cables (such as UL/TÜV). We can also procure and replace materials or brands specified by the customer to ensure system compatibility.

4. Are your wire harnesses UL or other internationally certified?

Our product lines use materials that comply with UL 758 / UL 94 / ISO 6722 / RoHS / REACH and other standards, and are manufactured in accordance with ISO 9001 and ISO 14001 systems. If required for a project, we can assist in providing third-party test reports or certification numbers.