Cable Assembly vs Wire Harness:Difference Between Cable Assembly and Wire Harness

Home » Cable Assembly vs Wire Harness:Difference Between Cable Assembly and Wire Harness

The blog will be centered around cable assembly vs wire harness. Tell you about difference between cable assembly and wire harness.

In today’s increasingly complex electronic, electrical and mechanical systems, the terms Cable Assembly and Wire Harness are often used interchangeably. In reality, however, there are significant differences in their structural form, functional characteristics, manufacturing processes, operating environments, and cost components.

Why do need to distinguish between cable assembly and wire harness?

It is important for engineers, purchasers, program managers and even customers to understand and use these two terms accurately. This not only helps with better selection and efficient communication, but also avoids misunderstandings and the risk of costly rework during product development, manufacturing, and assembly.

Let’s take an example. When designing an electrical system for outdoor industrial equipment, if Cable Assembly, which is supposed to be shielded, waterproof and tensile, is mistakenly selected for Wire Harness, which is an open structure with only simple strapping protection, the finished product may be exposed to the risk of water ingress, interference, poor contact and even safety accidents in the course of use. On the other hand, if a high-specification, higher-cost Cable Assembly is used for a short distance wiring in a vehicle, it will result in a waste of resources and redundancy of space.

Therefore, clarifying the definition and difference between “Cable Assembly” and “Wire Harness” is not only a matter of terminology, but also the key to project success and product reliability.

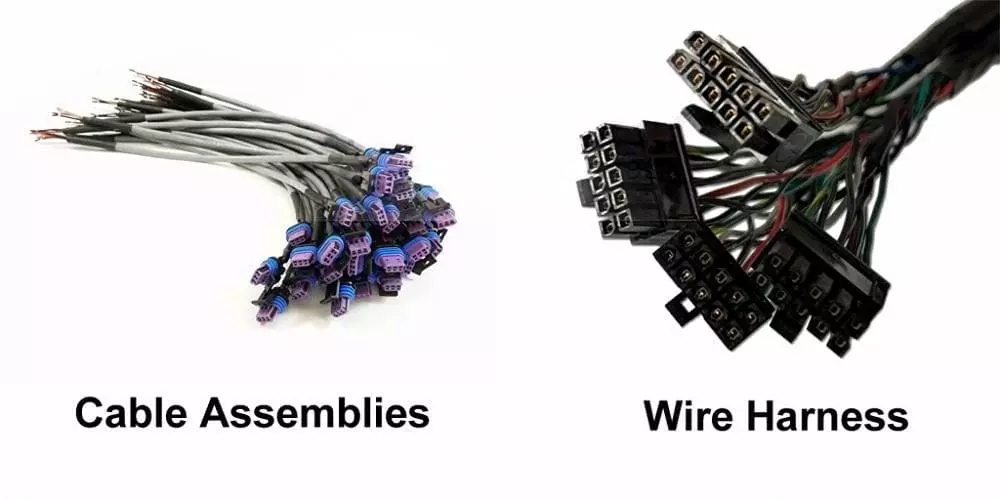

What is a Cable assembly?

Cable Assembly is a cable system. This system is designed so that one or more cables can be professionally assembled, terminated, jacketed, and encapsulated into a ready-to-use system according to specific functional requirements. This system contains pre-assembled terminals, connectors, sheathing layers, and waterproof construction. In addition, it is electrically tested before it can be delivered as a functional module.Cable assembly is used in environments that require high levels of electrical performance, protection, and structural integrity.

Unlike Wire Harnesses, which have an open structure and visible cables, Cable Assemblies emphasize “all-in-one packaging” and “complete functional components”. Typical Cable Assemblies utilize multi-core cables or shielded signal/power cables with specific interfaces (e.g., circular airline plugs, rectangular industrial connectors, RF headers, etc.) integrated at both ends.

Typical features of Cable Assembly:

- High protection: IP65/IP67 waterproof and dustproof rating. Strong resistance to oil, corrosion and temperature.

- Structural integrity: usually finished components. Installed and ready to use, avoiding field wiring errors

- Strong electrical performance: supports high-speed transmission, EMC shielding, and constant impedance control.

- High customization flexibility: termination and molding design can be made according to specific equipment interfaces, environmental dimensions, bending radius and other requirements.

What is a Wire Harness?

Wire Harness refers to the orderly bundling of multiple individual wires or cables together in accordance with electrical connections. It is then organized and protected by materials such as cable ties, fabric tape, heat shrink tubing, and corrugated tubing. Thus, it becomes a clearly structured assembly that is easy to install and wire. It is one of the most common electrical connection solutions in vehicles, appliances, and industrial equipment.Wire harnesses emphasize alignment management, clear connection relationships and structural modularity.

Wire Harnesses typically consist of wire, connectors, terminals, insulation, marking labels, etc. Unlike Cable Assembly, Wire Harnesses are cut individually, routed wire by wire, and terminals are inserted by hand. Unlike Cable Assemblies, Wire Harness wires are cut individually, routed one by one, and terminals are inserted by hand. The external structure is mostly open or semi-open, which is convenient for maintenance, rewiring and expansion. Therefore, it is more suitable for systems with fixed space, stable internal environment and easy maintenance.

Typical features of Wire Harnesses:

- Flexible structure: the cable can be bent and adjusted according to the shape of the space, suitable for complex wiring environment

- Relatively low cost: common materials, simple processing technology, suitable for rapid production of high-volume

- Maintenance-friendly: cable visualization, easy to repair, replace and diagnose at a later stage

- Widely used in automobiles and home appliances: e.g. dashboard wiring harnesses, door control wiring harnesses, washing machine internal wiring

Cable Assembly vs Wire Harness Comparison Table

| Comparison Item | Cable Assembly | Wire Harness |

|---|---|---|

| Structure | Fully enclosed multi-conductor cable with connectors | Bundled individual wires, semi-open structure |

| Flexibility | Integrated and robust, lower flexibility | Highly flexible, suitable for tight routing |

| Protection Level | High (waterproof, dustproof, EMI shielding) | Basic protection, suitable for internal use |

| Manufacturing | Custom-built, includes molding, shielding, sealing | Standardized process: cutting, crimping, bundling |

| Cost | Higher per unit, but with better performance | Lower cost, ideal for mass production |

| Typical Use Cases | Medical devices, telecom, defense, EV high-voltage | Automotive interiors, appliances, control panels |

| Maintainability | Sealed structure, harder to disassemble | Visible wires, easier to diagnose and replace |

1. Cable Assembly vs Wire Harness: Structure

- Cable Assembly: Usually a pre-molded complete structure, consisting of one or more multi-core cables. Both ends have been connected to a standardized plug, the whole with the outer jacket, encapsulation, sealing and other processing, forming a “plug and play” electrical components.

- Wire Harness: Bundled from several individual wires, which can be integrated together by means of fabric tape, bellows, zip ties, etc. The structure is open, with clearly spaced wires. However, the structure is open and the wires are clearly spaced, which makes it easy to organize the wires during installation or later modification.

2. Cable Assembly vs Wire Harness: Flexibility

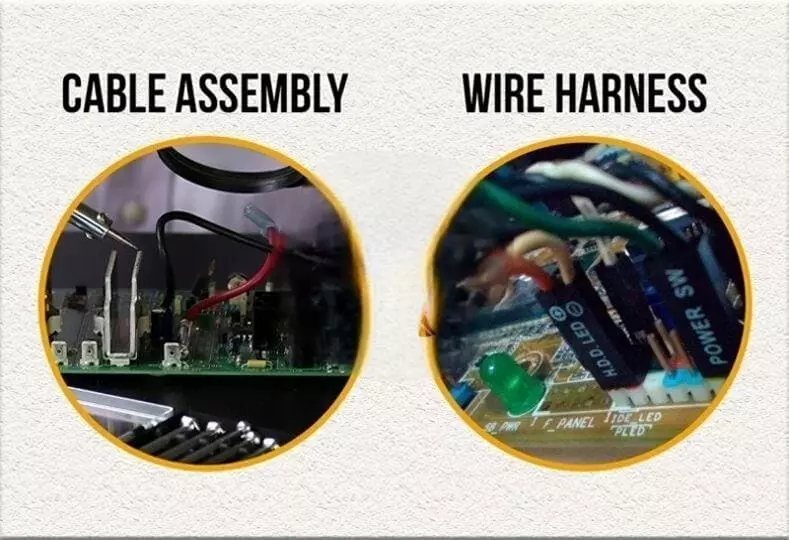

- Cable Assembly: Relatively low flexibility due to the fixed structure of the overall package. Therefore, it is suitable for the scenario where the wiring path is clear and the space is stable. For example, inside medical equipment or high-voltage cable connections.

- Wire Harness: Constructed of individual wires that can be freely bent and wrapped around obstacles. It is therefore ideally suited for applications within systems with restricted space or complex paths. For example, behind the dashboard of a car or in door cabling.

3. Cable Assembly vs Wire Harness: Protection Level

- Cable Assembly: With excellent mechanical protection, electromagnetic shielding, waterproof sealing and other capabilities, it can withstand harsh environments (e.g., outdoor, humidity, high temperature). Many products meet IP65-IP69K or even higher ratings.

- Wire Harness: Typically used in internal environments or confined spaces, protection depends on the external covering material (e.g. bellows, tape) and is suitable for lower risk applications.

4. Cable Assembly vs Wire Harness: Cost Structure

- Cable Assembly: Higher cost per piece due to its complex structure, variety of materials, and high packaging requirements. However, it is suitable for high-value and high-reliability application scenarios.

- Wire Harness: Common materials, mature technology, lower unit cost. Suitable for budget-sensitive or non-extreme environment demand projects.

5. Cable Assembly vs Wire Harness:Typical Use Cases

- Cable Assembly: Commonly used in equipment requiring high protection and high signal integrity. Such as: medical monitors, outdoor cameras, high-voltage fast-charging cable, electric vehicle connecting lines, military portable communication modules.

- Wire Harness: Widely used in automobile, home appliance, industrial control system and other fields. Such as car door control harness, washing machine control line, electrical control cabinet wiring, etc..

When to Use a Wire Harness vs a Cable Assembly?

After understanding the structural differences between Wire Harness and Cable Assembly, the central question is: which one is more suitable for you in the actual project?

The answer depends on the following key factors: usage environment, functional requirements, cabling space, cost considerations, maintenance frequency, etc. Below we compare by application scenarios to help you quickly determine the direction of selection.

Scenarios where Wire Harness is suitable:

1. Internal environments with limited space but complex wiring

such as automotive dashboards, door controls, air-conditioning control panels, industrial control cabinets, etc.. These applications require a lot of branch wiring in a small space. Wire Harness is flexible and can be customized.

2. Internal connection of equipment, environmental stability

For example, household appliances (washing machines, refrigerators), medical equipment, industrial control cabinets, such as internal module connection. These applications need to be anti-interference, but the protection requirements are not high, the use of wiring harness can reduce costs.

3. Require maintenance or replacement

The open structure of Wire Harness makes it easy to identify the location, color and function of each wire. Therefore, it is more suitable for systems that require regular maintenance or upgrading.

4. Mass production, cost control is preferred

such as OEM models, standard electrical appliances, and industrial control box harnesses. Adopting standardized processing and assembly processes saves manufacturing and assembly costs.

Scenarios suitable for using Cable Assembly:

1. Outdoor or harsh environment applications

such as security cameras, outdoor communication base stations, electric vehicle charging systems, outdoor lighting, rail transportation, etc. Cable Assembly provides encapsulation, waterproof, dustproof and temperature and corrosion resistance to adapt to harsh environments.

2.Need high frequency, low interference or high voltage transmission

High speed signal cable, RF cable, electric vehicle high voltage cable in communication, medical, military and other industries. These applications rely on Cable Assembly shielding, impedance control and precision manufacturing.

3. Emphasize the aesthetics and plug-and-play installation

Some high-end equipment, consumer electronics, brand chassis and other high requirements for the appearance and assembly efficiency. Cable Assembly is highly integrated and the finished product has a uniform appearance, which makes it easy for end-users to deploy quickly.

4. Customized Interface or Modular Connection Requirements

If you need to work with specific plugs and peripheral interfaces, Cable Assembly can be molded in one piece according to interface specifications, directionality, and anti-dulling design.

How do you choose the right program for you?

The choice of Wire Harness or Cable Assembly requires a combination of your project characteristics and end-use environment.

| Decision Factor | Recommended Option |

|---|---|

| Cost-sensitive, large volume production | ✅ Wire Harness |

| Complex routing, limited space | ✅ Wire Harness |

| Outdoor use, waterproof requirements | ✅ Cable Assembly |

| High-frequency or EMI-sensitive signals | ✅ Cable Assembly |

| Integrated appearance, plug-and-play | ✅ Cable Assembly |

| Requires future maintenance or repair | ✅ Wire Harness |

Manufacturing Differences Between Cable Assemblies and Wire Harnesses

Although Cable Assembly and Wire Harness are both components of an electrical connection system. However, their manufacturing processes, equipment configurations, standards requirements and quality control methods differ significantly. These differences position them differently in terms of cost, lead time, process complexity and application environment.

Difference 1 : Process Flow Differences

In terms of manufacturing processes, there is a fundamental difference between cable assembly and wire harness.

The manufacturing process of Wire Harness is more inclined to standardization, mass production and modular operation. It emphasizes clear wiring, reliable terminal connection and neat structure.

Cable Assembly is a finished component level manufacturing process, which is more like the manufacturing of a “complete cable product”. Emphasis is placed on protection, structural integrity and customized interface matching.

Difference 2 : Manufacturing Complexity

- Wire Harness is relatively simple to manufacture. It can be highly standardized, suitable for parallel production, manual and semi-automatic combination, suitable for high-volume and fast-paced orders.

- Cable Assembly is a customized product. Small batch size but complex specifications, involving molds, shielding, sealing and other aspects of the process is flexible but the processing cycle is relatively long.

Difference 3 : Equipment & Tooling Requirements

| Equipment Type | Wire Harness | Cable Assembly |

|---|---|---|

| Wire Cutting & Stripping | Standard automatic wire cutting and stripping machines | Machines that support multi-core cables with sheath positioning |

| Crimping Equipment | Pneumatic or servo crimping tools for standard terminals | Precision crimping with alignment fixtures for high-reliability connectors |

| Connector Assembly Tools | Insertion benches, manual tools, tie wrap guns | Custom jigs, torque tools, anti-reverse alignment devices |

| Overmolding / Potting | Typically not required | Thermoplastic molding machines, epoxy potting equipment |

| Testing Systems | Continuity testers, pin-out verification testers | Includes Hi-Pot testers, insulation resistance, EMI shielding and IP rating testers |

Difference 4 : Quality Standards and Testing

Wire Harness testing standards are based on IPC/WHMA-A-620. focus:

- Crimp quality (pull-off force, profile analysis)

- Correct pin correspondence

- Intermittent and insulating properties

Cable Assemblies are required to meet, in addition to the above basic requirements:

- IP rating certification (e.g. IP65/IP67/IP69K)

- Shielding integrity (EMI suppression)

- Plug life, tensile strength, temperature rise performance

- Reliability testing (high temperature aging, vibration, salt spray, etc.)

Comprehensive Wiring Solutions by Linkwings

In the rapidly evolving era of smart manufacturing, electrification, and customization, Linkwings is committed to providing high-quality, flexible, and engineering-supported wiring harness and cable assembly solutions to our customers around the world. We are not just a manufacturer, but a team of engineering professionals who are familiar with design, process, standards and delivery cadence.

Whether you are a large vehicle platform, an automation equipment integrator, a new energy project team, or a small to medium sized customer looking for a reliable supply chain, Linkwings can match you with the most appropriate wiring harness manufacturing model and service support.

Conclusion: Beyond Terminology—Choose What Fits Best

In this article, we take a closer look at the difference between Cable Assembly and Wire Harness. It can be seen that although these two terms are often used interchangeably in everyday use, in professional manufacturing and engineering applications, they represent completely different product forms and technical realizations.

Wire Harness is more suitable for flexible cabling, internal use and cost-sensitive projects. Cable Assembly is more suitable for high protection and high performance requirements. There is no absolute advantage or disadvantage between the two, the key lies in whether they are highly compatible with your project environment, interface requirements and usage scenarios.

📌 Linkwings, as a professional wire harness manufacturer and cable assemblies manufacturer, has the ability to design and deliver a full range of products covering Wire Harness and Cable Assembly. No matter what kind of cable system you need, we can provide you with a full range of services from selection consulting, drawing review, prototype manufacturing, to volume delivery. We can help you easily complete the transformation from design to mass production.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In