Home » Car Battery Ground Wire

Car Battery Ground Wire —— Custom and Bulk Supply of Car Battery Ground Wires

Linkwings offers a wide range of Car Battery Ground Wire products in various specifications, including bare copper wire, tin-plated copper wire, high-current grounding wire, ring-end wire, and braided grounding tape. These products are widely used in different platforms such as gasoline-powered vehicles, new energy vehicles, trucks, RVs, and modified vehicles.

Custom Car Battery Ground Wire from Wire Harness Manufacturer

In automotive electrical systems requiring reliable grounding, customized car battery ground wires not only affect starting performance but also directly impact the overall electrical stability and safety of the vehicle. As a professional wire harness manufacturer, Linkwings specializes in providing grounding wire solutions optimized for structural integrity, current matching, and corrosion resistance. We serve a wide range of industries, including passenger vehicles, commercial vehicles, modified vehicles, and new energy vehicle manufacturers.

We are equipped with advanced crimping, stripping, welding, and testing equipment. We offer full-process customization from wire gauge selection, connector selection, to sheath material, ensuring that each ground wire can operate stably under high current transmission and complex environmental conditions. Choosing Linkwings means choosing a true expert in customized wiring harness manufacturing for automotive electrical systems.

Car Battery Ground Wire

Linkwings offers a variety of Car Battery Ground Wire products with different structures and functional configurations to meet the grounding needs of different vehicle models, current ratings, and complex operating conditions. All products are customizable and can be precisely matched and mass-produced according to customer drawings, interface requirements, current parameters, and environmental requirements.

Ring Terminal Ground Wire

- Features: Double-ended copper or tin-plated copper ring terminals, securely crimped, easy to install.

- Applications: Commonly used in passenger cars to connect the negative terminal of the battery to the chassis or engine grounding point.

- Specifications: 6AWG~1/0AWG, multiple hole sizes available.

Braided Copper Grounding Strap

- Features: Made of bare copper or tin-plated copper wire, it is flexible, highly conductive, and has good shock resistance.

- Applications: Suitable for flexible connections between engines and car bodies, chassis, etc.

- Supports bare braided or sheathed structures to enhance wear resistance and corrosion resistance.

Heavy Duty Ground Wire

- Features: Suitable for high-power starters or battery systems, thick wire diameter, low resistance.

- Applications: Heavy-duty trucks, construction machinery, negative terminals of new energy battery packs.

- Wire gauges available up to 4 AWG, 2 AWG, and 1 AWG, with oil-resistant and heat-resistant sheathing.

Anti-Corrosion Ground Wire

- Features: Tin-plated conductor, zinc-plated or sealed joints, salt spray resistant, excellent waterproof performance.

- Applications: Suitable for vehicle grounding systems in coastal, high humidity, and high corrosion areas.

- Can be combined with waterproof sheathing, heat shrink packaging, and other structural processes.

Custom Ground Cable Assemblies

- Features: Supports multi-segment combinations, mixed terminals, label coding, sheath molding, and other complex requirements.

- Applications: Complete vehicle electrical wiring modules, main harness connections, and multi-point grounding for power systems.

- Designed according to drawings, fully inspected before shipment to ensure consistency and compatibility.

| Parameter | Available Options / Description |

|---|---|

| Conductor Material | Pure copper / Tinned copper / Braided copper strap |

| Wire Gauge Range | 6 AWG – 1/0 AWG (based on current and resistance requirements) |

| Rated Current | 60A – 300A (depending on gauge and length) |

| Terminal Type | Ring terminal / L-type / Fork / Double-crimp / Custom design |

| Terminal Finish | Tin-plated / Zinc-plated / Silver / Corrosion-proof coating |

| Jacket Material | No jacket / PVC / XLPE / Heat shrink / Nylon braided sleeve |

| Jacket Color | Black / Red / Yellow / Blue / Custom color coding |

| Cable Length | 10 cm – 200 cm (fully customizable) |

| Protection Level | IP54 / IP65 / IP67 / IP68 (with waterproof sealing options) |

| Labeling & Marking | Laser marking / Heat shrink label / Printed code / Barcode tags |

| Testing Standards | Continuity / Pull force / Insulation resistance / Resistance / Visual |

Advantages of Car Battery Ground Wire

In automotive electrical systems, ground wires may be small, but they carry the critical current path between the battery negative terminal and the entire vehicle circuit. As a professional wire harness manufacturer, Linkwings offers Car Battery Ground Wire products with the following significant advantages:

- High-purity copper conductors with low resistance ensure rapid engine start-up

- Tin-plated or corrosion-resistant treatment, suitable for humid, salt spray, and other harsh environments

- Multiple terminal crimping processes to prevent loosening and ensure stable electrical connections

- Customizable to vehicle models or applications at the drawing level

- All products undergo 100% continuity and tensile strength testing before shipment

Applications of car Battery Ground Wire

Linkwings’ Car Battery Ground Wire products are widely used in various vehicle platforms and electrical systems. They demonstrate outstanding performance, particularly in terms of high current transmission, harsh environment adaptation, and structural customization.

Passenger Vehicle Grounding Wire

In traditional gasoline-powered vehicles and mild hybrid systems, the battery negative terminal must be reliably connected to the vehicle body or engine block via the Battery Ground Wire. Linkwings’ custom ground wire solution for a Japanese-Korean automotive manufacturer features 6AWG tin-plated copper conductors, heat-resistant PVC insulation, and dual compression ring terminals, ensuring rapid and stable engine starting even in low-temperature environments.

Heavy-duty trucks / construction vehicles high-current grounding wire

Heavy-duty diesel vehicles and construction machinery vehicles have high starting currents and operate in complex environments, placing extremely high demands on the current-carrying capacity and structural durability of grounding wires. We have supplied a European commercial vehicle manufacturer with bulk quantities of 2AWG high-conductivity grounding wires, equipped with galvanized steel terminals and braided sleeves to effectively enhance seismic resistance and corrosion resistance. These wires have operated stably in mining areas and high-humidity regions for over three years without any reported faults.

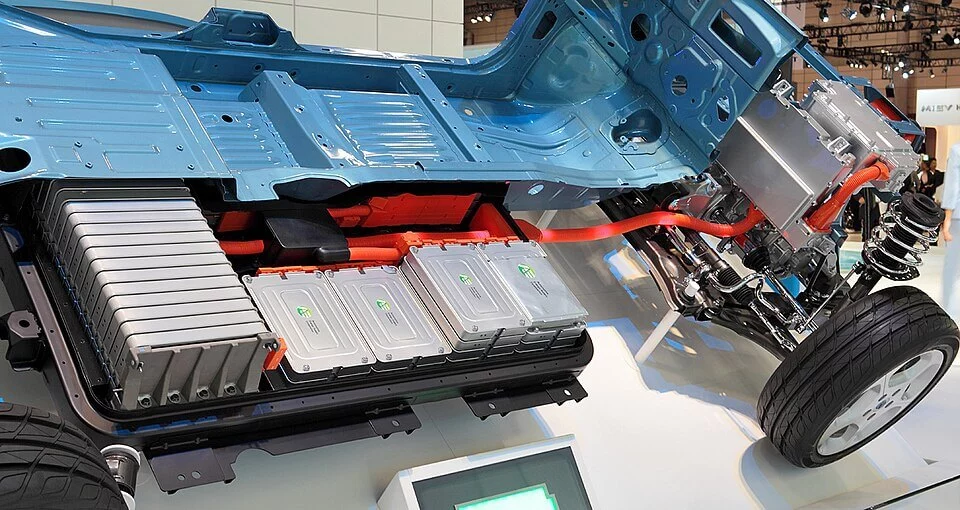

RV / New Energy Vehicle Battery Pack Negative Lead

In recreational vehicles and new energy power systems, battery packs are typically installed on the chassis or away from the main control module, requiring a stable negative circuit. Linkwings customized 1AWG battery negative wires with heat-shrink waterproof packaging for a North American recreational vehicle brand, with a length exceeding 1.5 meters. This solution addressed voltage drop and safety connection issues in long-distance wiring, earning unanimous praise from customers.

Modified Vehicle High-Power Audio/Lighting System Ground Upgrade Cable

In the modified vehicle market, many users add high-power amplifiers, LED light assemblies, and other equipment, placing higher demands on the current capacity and contact stability of ground wires. The 4AWG tinned copper upgrade ground wire we provide can effectively reduce system noise and voltage fluctuations, and has been widely used in the automotive modification markets of Southeast Asia and the Middle East.

FAQs about Car Battery Ground Wire

1. What is the function of a car battery ground wire?

The car battery ground wire is responsible for connecting the negative terminal of the car battery to the car body or engine, and is a key grounding channel in the electrical circuit of the entire vehicle. Its quality directly affects the starting performance, electrical system stability, and anti-interference ability of electrical appliances.

2. What is the difference between tin-plated copper and bare copper?

Tin-plated copper has better corrosion resistance and is suitable for humid, high salt fog, or long-term exposure environments, with a longer service life. Bare copper has slightly better electrical conductivity but is more prone to oxidation, making it suitable for cost-sensitive or dry environment applications.

3. Do you support waterproof grounding wires?

Yes. We can install heat-shrinkable waterproof tubing, sealant, or waterproof terminals at the joints to achieve IP65 to IP68 protection ratings. Suitable for outdoor use in RVs, construction vehicles, and other applications.

4. Can you provide samples? What is the minimum order quantity?

Linkwings supports sample customization and sample evaluation. The MOQ for regular products is generally 50 to 100 pieces. The specific MOQ and delivery time can be flexibly negotiated based on the complexity of the structure and customization requirements.