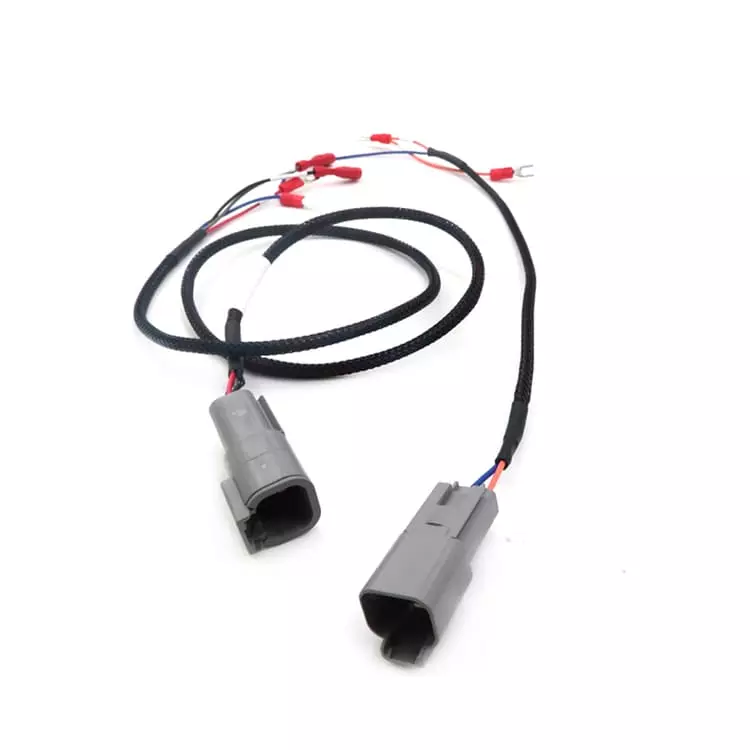

Reliable Custom Automotive Wiring Harness Manufacturer

Linkwings has more than 10 years of experience in automotive wiring harness manufacturing. We provide one-stop customized service from drawing design, selection confirmation, sample proofing to bulk delivery. Widely used in traditional fuel vehicles, new energy vehicles, electric two-wheelers, charging piles, intelligent cockpits, ADAS systems and other fields.

get automotive harnesses from Custom automotive wiring harness manufacturer

Choosing a professional custom automotive wiring harness manufacturer means that you will get an exclusive connection solution that meets the requirements of the entire vehicle system structure, electrical performance and application environment. Whether it is the main harness, CAN bus, power battery harness, or camera, radar, door control and other branch harnesses, we can customize the structural design and process according to the drawings, interfaces or functional requirements. We ensure that the wiring harnesses are efficiently adapted to the whole vehicle system and are plug-and-play.

As a wiring harness manufacturer with IATF 16949 quality system and many years of experience in OEM, Linkwings provides one-stop service from selection, prototyping, testing to mass delivery. Linkwings also supports professional requirements such as multi-brand terminal interfacing, automotive gauge wire selection, EMC shielding structure treatment, etc. Get high-quality automotive wiring harnesses now to empower your project with stable, efficient and safe electrical connections.

view linkwings Types of Automotive Wiring Harnesses

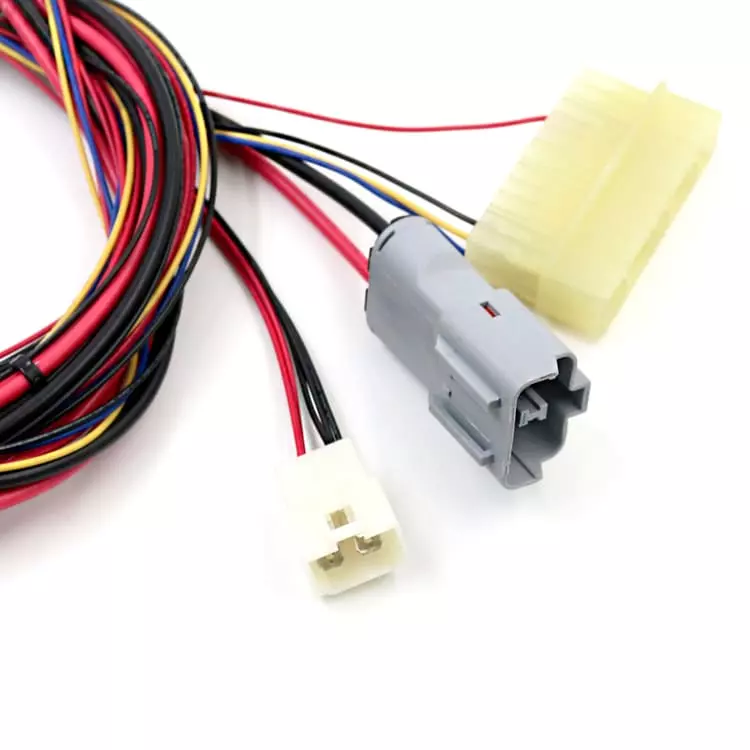

There are many types of automotive wiring harnesses, and different functional modules have strict requirements on the structure, size, material and connection methods of the wiring harnesses. Linkwings provides a wide range of customised wiring harnesses covering the key systems of the whole vehicle, which are applicable to multiple platforms such as traditional fuel vehicles, new energy vehicles, electric motorbikes, charging piles, and so on.

What We Offer

As a professional Custom Automotive Wiring Harness Manufacturer (CAWHM), Linkwings provides customers with a full range of services from structural design, material selection to terminal processing and testing and delivery. Linkwings meets the electrical connection needs of all types of vehicles and modules, such as traditional fuel vehicles, new energy vehicles, motorbikes, and charging piles.

| Service Item | Details |

|---|---|

| Custom Design Support | Support 2D/3D harness design and BOM creation based on drawings, samples, or interface definitions. System-level optimization for vehicle wiring available. |

| Full Automotive Harness Types | Manufacturing of main harnesses, CAN bus, lighting harnesses, battery module harnesses, door control, instrument clusters, etc. |

| Connector & Terminal Matching | Compatible with original brands like TE, AMP, Sumitomo, Molex, KET, Deutsch, etc. Support OEM-specified or cost-effective alternatives. |

| Automotive-grade Cable Selection | Use of AVSS, FLRY, TXL, XLPE, and other ISO/SAE/JASO compliant wires. High performance in temperature, oil, abrasion resistance. |

| Comprehensive Processing Capabilities | Crimping, soldering, corrugated tubing, heat shrink wrapping, overmolding, waterproof sealing, labeling, keyed connector assembly. |

| Certified Delivery & Documentation | In compliance with IATF 16949. Support for IMDS material reports, PPAP documentation, RoHS/REACH compliance files. |

Sample & Custom Process for automotive wiring harness

We have an efficient engineering response mechanism and flexible sampling capability. Therefore, we can quickly complete the structural confirmation, sample production and small batch verification according to customer requirements, reduce development risks and speed up project implementation.

📍 Step 1: Requirements Submission

Customer provides drawings, interface definitions, BOM sheets, sample photos or description of the use environment.

📍 Step 2: Engineering Evaluation

Our engineers evaluate the feasibility based on the structure and terminal configuration, and confirm the key parameters (wire gauge, terminal type, waterproof rating, etc.).

📍 Step 3: Structural Design and Material Confirmation

Produce wiring harness unfolding diagrams according to customer requirements, select suitable wires, jackets, terminals and connectors, and create a preliminary BOM list.

📍 Step 4: Quotation and Delivery Confirmation

Provide formal quotation, delivery arrangement and sample specification document.

📍 Step 5: Sample Production

Produce samples according to the confirmed programme, conductivity test, tensile test, waterproof test (if required).

📍 Step 6: Sample Delivery and Customer Confirmation

Customers evaluate the performance and structure of the samples, give feedback, we support free optimisation and adjustment for 1 time.

📍 Step 7: Formal order and batch switching

Enter mass production stage after sample confirmation, support label/packaging customisation and factory full inspection.

what are automotive wiring harnesses?

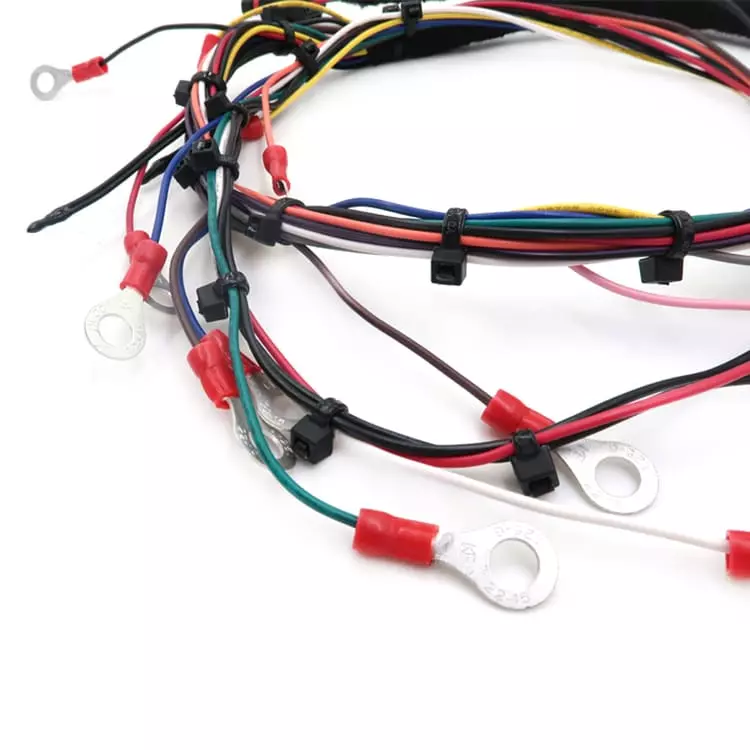

Automotive Wiring Harnesses refers to the complete set of wiring systems used to transmit electrical energy and signals in the interior of an automobile. It consists of wires, connectors, terminals, sheaths, bellows, tapes and other components, and is used to connect the various electronic and electrical modules of the car (such as engine, lights, instrumentation, air conditioning, sensors, etc.) to realize the electrical function of the whole car. Automotive wire harnesses are mainly composed of the following parts:

- Wires

- Connectors

- Terminals

- Sleeves

- Branches

why use automotive wiring harnesses?

Automotive wiring harness is an indispensable core connecting component in the electrical system of the whole vehicle. It realizes stable power supply and data transmission for engine, instrument, lighting, air conditioning, sensors, entertainment system and other modules by integrating power and signal wires in a unified structure. Its standardized design not only improves the assembly efficiency of the entire vehicle, but also significantly reduces the failure rate and maintenance costs.

With the development of electrification and intelligentization of automobiles, wiring harness has been upgraded from a simple wire harness to a complex information interaction system. Modern automotive wiring harnesses support CAN, LIN, Ethernet and other communication protocols, with good anti-interference and environmental adaptability, and are the key infrastructure for realizing the functions of intelligent cockpit, ADAS, high-voltage power system and so on.

Applications of our automotive wiring harness

Lorem ipsum dolor sat amet,consectetur adipiscing elit。 Ut elittellus,luctus nec ullamcorper mattis,pulvinar dapibus leo。

Typical Applications:

- Engine compartment main harness (ECU, sensors, injectors)

- Body wiring harness (headlights, taillights, door controls, power mirrors)

- Instrumentation wiring harness (combination meter, center control, buttons)

- Air conditioning control line, window lift control, sound system, etc.

Features:

Relatively mature structure, more branches, emphasizing high temperature, oil resistance, flame retardant and long-term reliability.

Typical Applications:

- High voltage powertrain harnesses (power battery, OBC, PDU, BMS, DCDC)

- Fast/slow charging connection harness (between charging port and controller)

- Low-voltage signal lines (CAN, LIN, MCU control lines)

- Battery pack internal monitoring harness (temperature, voltage, bus bar sensing lines)

Features:

High-voltage system needs to be voltage resistant and anti-electrocution, and the wiring harness needs to be strongly insulated, waterproof, EMI shielding, and comply with GB/T, ISO26262 and other safety standards.

Typical Applications:

- Battery and controller connection cables

- Lighting, steering, and instrumentation control wires

- Motor and driver wiring harnesses

- USB/charging interface, Bluetooth control module connection line

Features:

Small size, compact structure, high space utilization requirements, need to be anti-vibration, waterproof, high temperature resistance.

Typical Applications:

- Center control display wiring, instrument screen connecting wire

- Car camera, microphone, speaker harnesses

- Ambient lighting, USB, power module wiring harnesses

- Communication interface wires (CAN, Ethernet, LIN bus)

Characteristics:

Dense modules require lightweight wiring harnesses, small size, multi-functional combinations, low interference, and neat appearance.

Typical Applications:

- Front-view, rear-view, surround-view camera connecting cables

- Radar module connection line (millimeter wave, ultrasonic)

- Sensor interface cable for steering, braking, speed, acceleration, environment awareness, etc.

Features:

requires stable transmission signal, good shielding effect, high plug-in reliability, and supports high frequency/high speed transmission.

Typical Applications:

- Pile end charging module internal connection wires

- Communication module wiring harness (RS485, CAN)

- Touch screen, power module wiring harness

- Safety protection system and billing system wiring harness

Features:

Outdoor use scenarios are many, requiring high waterproof, lightning protection, UV protection level and long-term weather resistance.

Why choose Linkwings Automotive Wiring Harness?

Linkwings is a manufacturing company specializing in customized wiring harnesses and connectivity solutions. We have more than 10 years of experience in the industry, and our services cover a wide range of fields such as traditional fuel vehicles, new energy vehicles, electric two-wheeled vehicles, charging piles, intelligent cockpits, etc. We provide customers with high quality, high efficiency, strong adaptability, and high reliability. With “High Reliability + Fast Response + Engineering Service” as the core, we provide customers with high-quality, high-efficiency and strong adaptability of automotive wiring harness products.

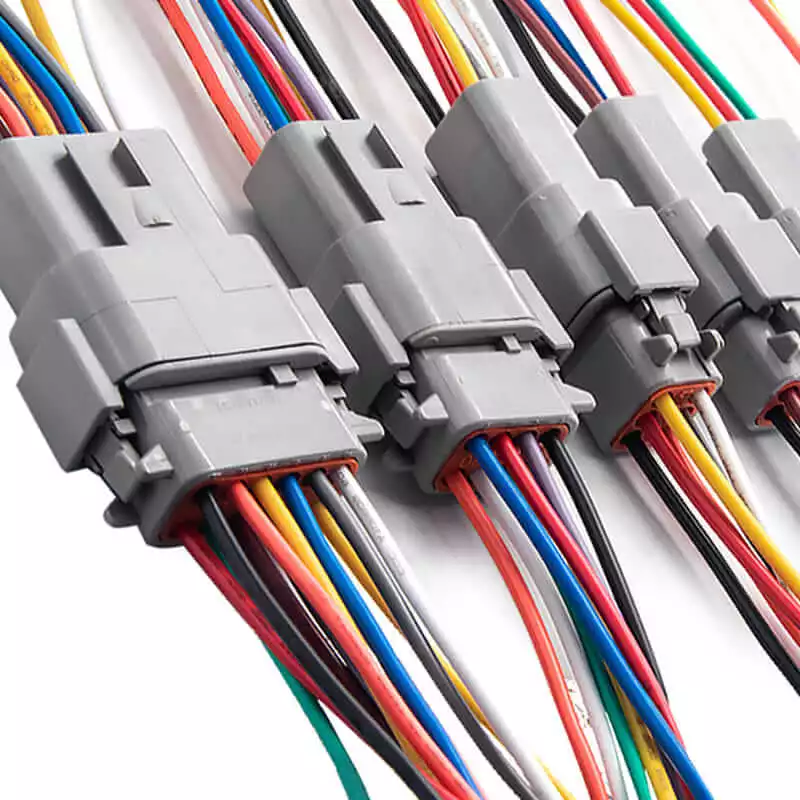

1. Experienced in the industry, supporting multiple types of vehicle platforms

Linkwings is familiar with various vehicle architectures, electrical interface standards and application requirements. We have a lot of experience in delivering trunk harnesses, battery harnesses, CAN buses, ADAS module harnesses, etc. We can provide platform customization solutions according to customer's vehicle and system requirements. We can provide platform customization solutions according to the customer's vehicle and system requirements, and quickly land on the ground.

2. Integration of engineering and production, supporting the whole process from drawing to delivery.

We are equipped with a professional engineering team that can assist customers with structural design, BOM selection, terminal substitution and sample optimization. We also have advanced automatic crimping, threading, injection molding, assembly and testing lines. We ensure that every step from sample proofing to batch delivery is efficient, standardized and traceable.

3. Strict Quality System, Compliance with Vehicle-Grade Standards

Linkwings strictly implements ISO 9001 and IATF 16949 quality management system, and all products comply with RoHS / REACH / IMDS / PPAP certification requirements. Before leaving the factory, 100% of the products are tested for electrical conduction, tension, appearance and other tests to ensure that each wire harness is stable, safe and reliable.

4. Flexible production and fast delivery capability

We support from small batch rapid prototyping to medium and large batch flexible switching. Regular samples can be delivered in 3~5 days, and we support customer-specified terminals, wires and packaging requirements. Suitable for aftermarket, OEM project, OEM development and other applications.

I don't have a drawing, can I customize it?

You can. You only need to provide the usage scenario, connector interface information, electrical function description or physical samples. Our engineering team can assist you with structural design, BOM recommendation, wire selection and other preliminary engineering support.

Do you use automotive grade materials?

Yes, we use automotive specification cables that comply with ISO/JASO/SAE etc. standards. Such as AVSS, FLRY, TXL, GXL, etc. The connectors support TE, AMP, Sumitomo, Molex, KET, Deutsch, etc. as original or high quality alternatives.

Is it possible to process terminals or connectors according to the brand specified by the customer?

We can. We can use terminals of specified brands (e.g. TE, Sumitomo, Molex) according to customer requirements. In addition, we support the selection of domestic compatible alternative models with better cost performance. We support the customer to provide materials or joint purchasing.