Home » Custom Engine Wiring Harness Solutions

Custom Engine Wiring Harness Solutions —— Built for Engineering Projects

Get Custom Engine Wiring Harnesses Solutions. Adapting to a Variety of Project Needs. Support Sampling, Small Batch, 3D Adaptation Design.

Get Custon Engine Wiring Harness Solutions from Wire Harness Manufacturer

When developing a powertrain or modification project, a standard wiring harness often fails to meet your specific requirements for ports, layout, and temperature resistance ratings. That’s when a custom engine wiring harness can take your project from chaos to order and quickly transition from prototype to mass production. We understand that every engine system is unique, so every wire, too, should be taken seriously.

As an experienced wire harness manufacturer, Linkwings understands the challenges that engineers and project leaders face in moving forward – changing requirements, tight timelines, and supply chain uncertainty. What we offer is not just a product, but a collaborative development experience: from drawing evaluation to prototype testing, engineers lead every step of the way, ensuring that every dollar you spend is spent on performance and reliability.

Why Choose Linkwings as Your Custom Engine Wiring Harness Supplier?

Linkwings is a high quality wiring harness manufacturer specializing in custom engine wiring harness solutions, founded by a group of engineers with backgrounds in electrical engineering, mechanical design and vehicle integration. We don’t just make wiring harnesses, we understand the depth of the fit between the engine, the electronic control system and the vehicle environment. Because of this, we can provide you not only products, but also a kind of professional service that “understands you”.

From the very beginning, we have served many powertrain R&D teams, ranging from racing cars, electric motorcycles, unmanned agricultural machines, to hybrid engineering prototypes. Over the years, we have accumulated a lot of practical experience in harness structure optimization, complex wire diameter matching, ECU interface adaptation, and harness stability under high temperature and high vibration environments. All these have helped us build a stable reputation in the industry.

Engineer-led communication

We understand that the people you interface with must be technically savvy, and every account manager at Linkwings is backed by a team of senior engineers.

Customizable+Floor-to-Floor

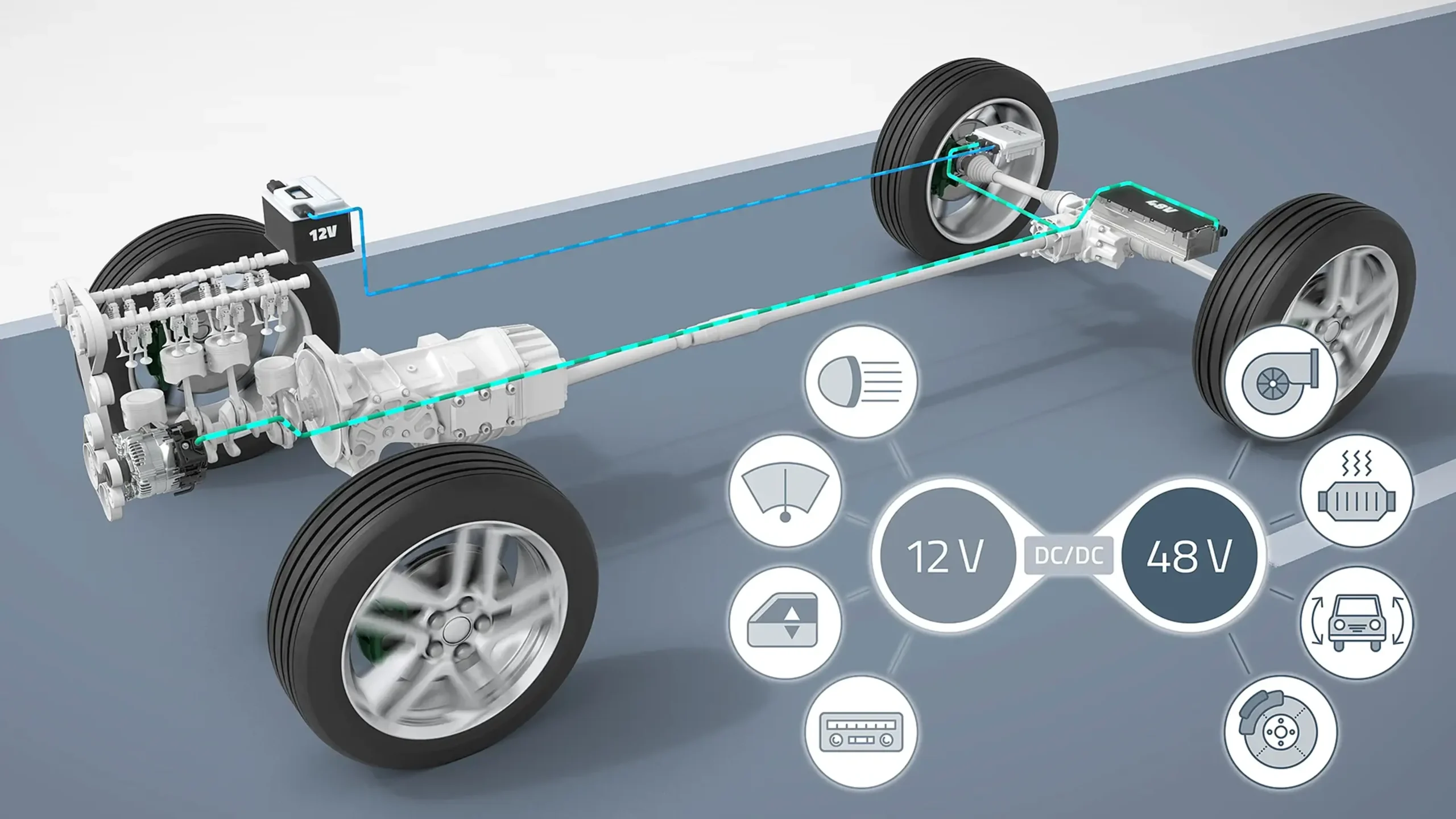

Whether it is for the complex cable layout of V-6 engine or the redundant wiring requirement under dual power system, we can provide reasonable solutions according to your project.

Full link quality control

Our factory is equipped with professional wiring harness processing and testing equipment. All products are 100% electrically tested before leaving the factory. And we can provide UL, ISO/TS16949 and other material or process certification support on demand.

Customer Satisfaction Number One

With over 85% of our clients coming from referrals between engineers, word-of-mouth is the asset we care most about. We welcome you to start working with us from small projects and use one experience to judge whether we are worth long-term cooperation.

Our Client Cases

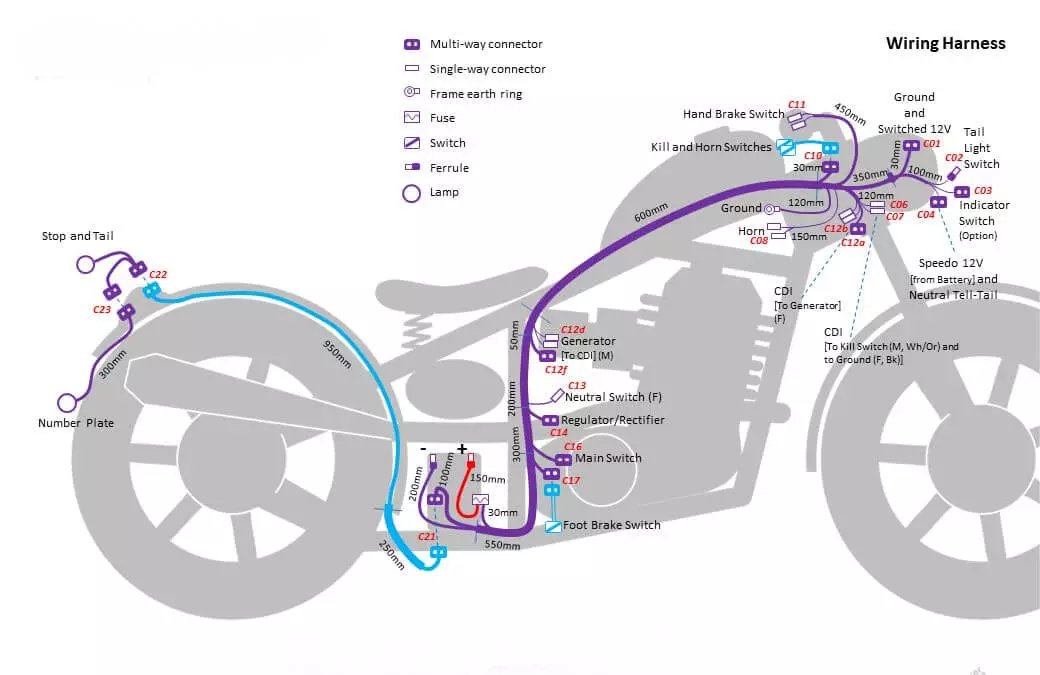

When an electric motorcycle startup brand from Southeast Asia needed to develop a lightweight electric scooter, Linkwings designed and manufactured an integrated wiring harness for the drive motor + battery + BMS + instrumentation. Highly flexible sheathing material was used to fit into the vehicle body space, and the harness was IP67 waterproofed for the rainy climate of the region. It took less than 4 weeks from prototype confirmation to small batch delivery, helping the customer to successfully complete the first round of road test.

When an agricultural automation equipment company developed a new unmanned harvester with a small diesel engine + RTK control module, Linkwings provided a customized engine harness and CAN bus integration solution. The wiring harness supports stable operation in high vibration scenarios and is reinforced against rodent bites. The customer is particularly satisfied with our understanding of the agricultural electronic control environment, and has already begun cooperation on the development of wiring harnesses for subsequent models.

For a European university research team developing a hybrid energy management system with frequent iterations and prototype wiring that required flexible plug-and-play and multiple changes, Linkwings created a modular plug-and-play wiring harness system that supported end-of-board connections, current sampling, and thermocouple integration. Detailed labeling diagrams and installation manuals were provided prior to delivery, greatly enhancing the efficiency of the experiment.

What is a custom engine wire harness?

Custom Engine Wiring Harness is a wiring harness assembly designed and manufactured for a specific engine system or vehicle layout. Unlike a standard generic wiring harness, a custom wiring harness is custom designed to meet the needs of your project.

Compared to standard parts, custom engine harnesses have several key features:

- Exact match to your interface and functional requirements

- Precisely adapted to the mounting structure

- Meets environmental and performance requirements

- Expandable and maintainable

Instead of compromising on generic wiring harnesses, customize your system once and for all. Linkwings, as a specialized wiring harness manufacturer, has the industry experience and flexible engineering capabilities to help you move from “wiring chaos” to “efficient deployment”. Linkwings has the experience and flexible engineering capabilities to help you move from wiring chaos to efficient deployment.

Who needs a custom engine wiring harness?

These following users are looking for our customized wiring harnesses almost every day:

- Small-volume vehicle developers (electric motors, agricultural machinery, construction machinery)

- Scientific research organizations / power labs (hybrid, hydrogen, alternative energy)

- Modified racing teams / powertrain upgrade programs

- Prototyping departments of OEM manufacturers

- Innovative hardware or powertrain start-up teams

FAQs about Custom Engine Wiring Harnesses

Q1: I don't have a complete drawing, can I customize the engine wiring harness?

Of course. As a leading custom wire harness manufacturer, Linkwings supports customization from many forms of input data. This includes hand-drawn sketches, original vehicle samples, 3D structural drawings, or simple interface descriptions. Our team of engineers will define interfaces, plan alignments and recommend materials based on the information you provide, ensuring that your customized engine wiring harness is both functional and safe.

Q2: Do your wiring harnesses meet industry certification standards?

We can provide UL, ISO, TS16949 certified materials or processes according to project requirements. All wiring harnesses are 100% tested for electrical performance (conduction, short-circuit, plug adaptation, etc.) before leaving the factory, and can be accompanied by insulation test and tensile test reports. Some special application scenarios (e.g. military, medical) can be directed to customize higher level specifications.

Q6: How to start the cooperation? Is it possible to assess the feasibility of the project first?

Welcome to communicate and evaluate first. You only need to provide the basic requirements (engine type, number of interfaces, function description, etc.), our engineering team can initially judge the difficulty and feasibility of the project. There is no need to prepare everything at the beginning, we can work with you to improve it step by step.