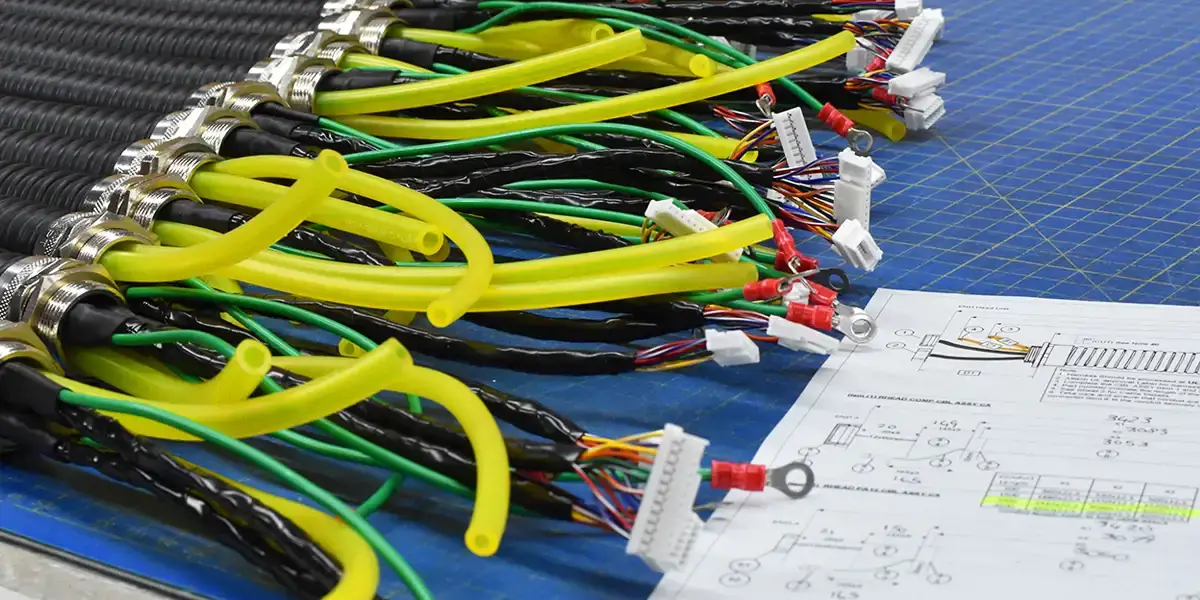

In electrical connections and wire harness manufacturing, different types of wire crimps are a critical process for ensuring stable, low-impedance, and reliable contact between wires and terminals. Different crimping methods not only affect electrical performance and mechanical strength but also determine the long-term reliability of wire harnesses in applications such as automotive, industrial, medical, and aerospace.

This article will provide a professional overview of common crimping types, their characteristics, and suitable applications. By referencing industry standards and selection guidelines, it aims to help you scientifically understand and choose the most appropriate crimping method.

What are Wire Crimps?

Wire Crimp is a mechanical process that securely connects wires to terminals. It enables stable and durable electrical connections without the use of solder. During the crimping process, the wire is compressed into the metal structure of the terminal, forming a tightly bonded unit to ensure low-impedance transmission and excellent mechanical retention.

Compared to traditional soldering or screw fastening, crimping offers higher efficiency and consistency. While soldering provides conductivity, it faces challenges such as process complexity, thermal effects, and inconsistent reliability in mass production. Screw fastening is prone to loosening due to vibration or temperature changes. Crimp technology, however, eliminates the need for additional heating and avoids the risk of mechanical loosening, making it ideal for large-scale wire harness production and automated assembly.

In terms of electrical and mechanical performance, crimping offers significant advantages:

- Low contact resistance: The tightly bonded metal contact surfaces ensure stable current transmission and minimize energy loss.

- Vibration resistance: Crimp joints exhibit high mechanical stability, making them suitable for vibration-prone environments such as automotive and aerospace applications.

- Long-term reliability: Since there is no risk of solder joint embrittlement or screw loosening, crimping maintains long-term stable performance in harsh environments.

For these reasons, Wire Crimp has become one of the most commonly used and reliable connection methods in modern wire harness manufacturing.

Different Types of Wire Crimps

In electrical connections and wire harness manufacturing, the crimping method directly affects the connection between the wire and the terminal. Different crimping types are designed for different wire structures, application environments, and electrical requirements. The following are some of the most common types of wire crimps and their characteristics.

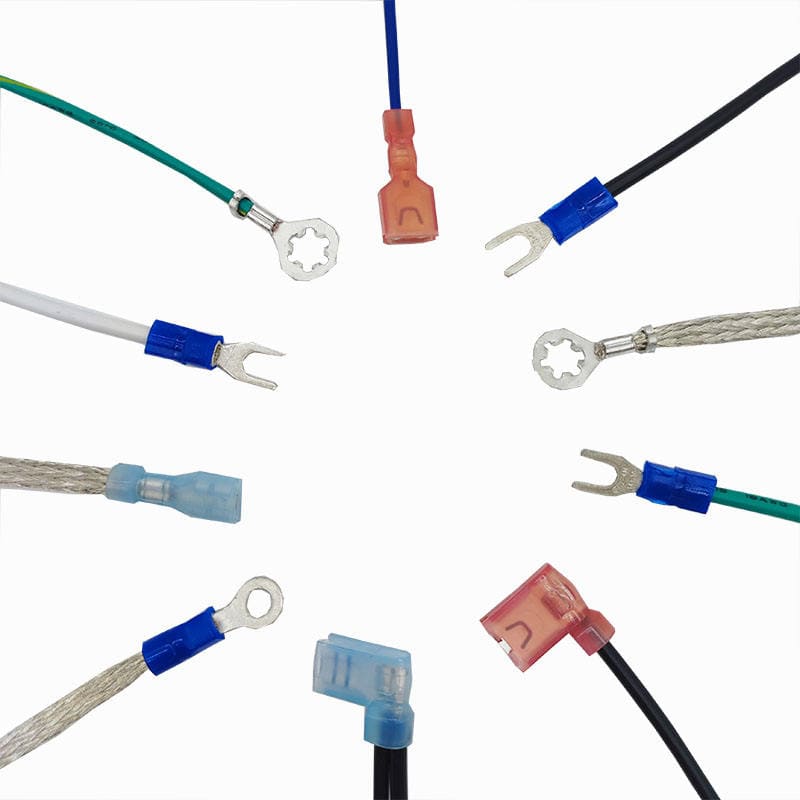

1. Insulated Crimps

Definition: Terminals with plastic or nylon insulated sleeves on the outside to protect exposed metal contacts.

Features:

- Prevents accidental short circuits and electric shocks, improving safety.

- The insulation layer also prevents moisture and dust from entering to a certain extent, improving environmental resistance.

- Common color distinctions (red, blue, yellow) correspond to different wire cross-sectional areas.

Typical applications: Home appliances, electric vehicles, low-voltage electrical systems, particularly suitable for compact spaces where contact with other metal components is likely.

2. Non-Insulated Crimps

Definition: The terminal body does not have an additional insulating sleeve; it is directly crimped and secured to the wire via metal contact.

Features:

- Simple structure with excellent electrical performance.

- Lower cost, suitable for large-scale applications.

- Higher requirements for installation and subsequent setup, ensuring environmental safety and wiring isolation.

Typical applications: industrial equipment, electrical cabinets, control panel wiring, widely used in scenarios where insulation requirements are low but reliable conductivity is essential.

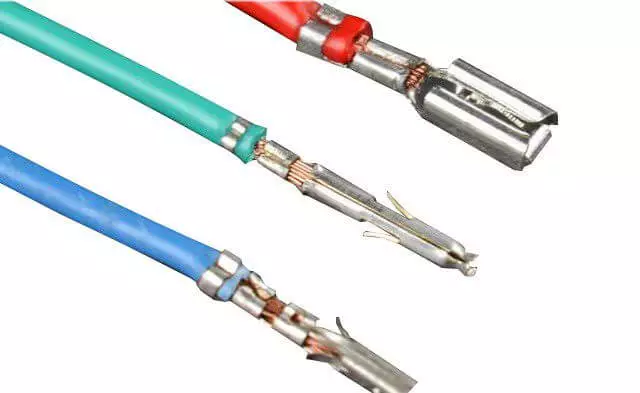

3. Closed Barrel vs. Open Barrel Crimps

Closed Barrel Crimps:

- Crimped using a closed metal tube with the wire, providing uniform crimping surfaces and high mechanical strength.

- Suitable for connecting cables with larger cross-sections.

- Commonly used in power equipment and high-current applications.

Open Barrel Crimps / F-Crimps:

- Terminals feature a “U”-shaped or “F”-shaped structure, facilitating rapid assembly with automated equipment.

- After crimping, both the conductor and insulation are securely held in place, enhancing tensile strength.

- This is the most widely used type in the automotive industry and electronic wiring harnesses.

4. Butt Connectors

Definition: Connecting two wires end-to-end and crimping them together with a metal tube to form a continuous circuit.

Features:

- Compact structure, suitable for wiring environments with limited space.

- Stable connection after crimping, but cannot be repeatedly disassembled and reassembled.

- Available in insulated and non-insulated types.

Typical applications: Cable extension, maintenance scenarios, automotive aftermarket modifications, and appliance repairs.

5. Ring, Spade, and Blade Crimps

Ring Crimp:

- The metal terminal is a closed ring shape and is secured with a bolt or nut.

- It has excellent vibration resistance and is virtually impossible to loosen during vibration.

- It is commonly used for power distribution and ground connections.

Spade Crimp:

- The terminal has an open “Y” shape, allowing it to be quickly inserted under a bolt and secured.

- Easier to install and maintain, but slightly lower vibration resistance than ring terminals.

- Widely used in electrical control cabinets and distribution panels.

Blade Crimp:

- Flat plate-shaped, used in conjunction with socket terminals.

- Facilitates modular design and quick replacement.

- Common in home appliances and automotive internal electrical connections.

6. Ferrule Crimp

Definition: Using metal ferrules to compress multiple strands of fine wires into a single unit, preventing the strands from separating.

Features:

- Improves contact reliability when connecting to terminal blocks.

- Prevents individual strands from breaking due to uneven screw crimping.

- Enhances electrical stability and durability.

Typical applications: Industrial control systems, automated equipment, robotics wiring.

7. Tube Terminals (Lugs/Tube Crimps)

Definition: Combining metal tube terminals with large-cross-section cables, typically requiring hydraulic crimping tools.

Features:

- Suitable for high-current transmission, providing a secure connection.

- High mechanical strength after crimping, capable of withstanding significant tensile force.

- Terminals are typically tin-plated to prevent oxidation.

Typical applications: power systems, renewable energy (solar, wind), heavy machinery, and the maritime industry.

How to Select Wire Crimp?

In practical applications, selecting the appropriate wire crimp directly impacts the electrical performance, mechanical stability, and overall lifespan of the wiring harness. Different crimp types are not interchangeable and must be selected based on specific electrical parameters, operating environments, and industry standards. The following factors are critical for crimp selection:

Step 1. Electrical Performance Requirements (Current/Voltage Rating)

The crimping method must be capable of handling the current and voltage required by the design. For high-current, large-cross-section wires, tubular terminal crimping (Lug/Tube Crimps) should be prioritized; in low-current control signal circuits, open barrel crimping (Open Barrel Crimps) or ferrule crimping (Ferrules) is more suitable.

Step 2. Operating environment (temperature, humidity, corrosive media)

If the application environment has high temperatures, such as engine compartments or industrial furnace surroundings, crimp terminals with high-temperature-resistant insulation materials should be selected. In humid or salt fog environments, such as ships or offshore wind power systems, terminals with tin-plated or nickel-plated coatings are recommended to enhance corrosion resistance.

Step 3. Mechanical Stress (Vibration, Bending, Tensile Force)

In automotive, aerospace, or industrial robotics applications, crimp connections must exhibit extremely high vibration resistance. In such cases, ring crimp terminals are typically the optimal choice, as their closed structure minimizes the risk of loosening under vibration. Open-end terminals (spade crimp) are suitable for connections requiring frequent maintenance or replacement.

Step 4. Standards and certifications (UL, SAE, MIL-Spec, ISO)

For export products or high-reliability industries (medical, military, aerospace), crimping methods must comply with corresponding international standards. For example, MIL-Spec Crimps have strict requirements in the military industry, while the automotive industry more commonly references SAE/ISO standards. When selecting a manufacturer, it is crucial to confirm whether their products have obtained these certifications.

Step 5. Cost and Production Efficiency

In large-scale automated production, open barrel crimps are widely used in the automotive and consumer electronics industries because they can be processed using high-speed automatic crimping machines, significantly improving efficiency and reducing costs. In small-batch, highly customized scenarios, however, ferrules or special-structure terminals with higher flexibility may be prioritized.

Why wholesale wire crimping from Linkwings?

When selecting a wire crimping wholesale supplier, users are most concerned about product quality stability, supply capacity, and whether it can meet the specific standards of their industry. As a professional manufacturer of wire harness and connection solutions, Linkwings has become a trusted partner for many customers thanks to its years of industry experience and strict quality control system.

- High-quality assurance: All wire crimps comply with international standards such as UL, SAE, ISO, and MIL-Spec.

- Comprehensive product range: We offer a variety of types, including insulated terminals, non-insulated terminals, ring-shaped, fork-shaped, sleeve-shaped, and tubular designs.

- Customization Services: We offer customized solutions for special sizes, surface treatments, corrosion resistance, and other specific requirements to meet customers’ unique application needs.

- Stable Supply Capacity: With automated production and large-scale production capacity, we support both small-batch pilot production and large-scale wholesale orders.

- Professional Technical Support: Our team of engineers provides product selection guidance, process optimization, and after-sales service to ensure a seamless customer experience.

FAQs

Q1: Which is more reliable, crimping or welding?

A: In most industrial and automotive applications, crimping is generally more reliable than welding. Crimp connections not only have lower electrical resistance but also effectively resist vibration and mechanical stress, making them ideal for large-scale wire harness production.

Q2: Can multiple different wire crimps be used in a single harness?

A: Yes. Complex harnesses often include various types of wires, such as signal wires, power wires, and ground wires. Different crimp terminals should be selected based on wire specifications and functionality to ensure overall performance and reliability.

Q3: How can one ensure that wire crimps meet industry certifications?

A: It is necessary to select manufacturers with strict quality systems and certification qualifications. Linkwings’ products meet UL, SAE, ISO, and MIL-Spec requirements and undergo full-process testing to ensure that the electrical and mechanical performance of the crimping meets standards.

Conclusion

In practical applications, understanding and selecting the appropriate types of wire crimps is critical to ensuring the electrical performance, mechanical stability, and long-term reliability of wire harnesses. From common ring terminals and fork terminals to open terminals suitable for automated assembly, and tubular terminals designed for high-current transmission, each type of crimping offers unique advantages and is suited for specific applications.

As a professional wire crimp manufacturer, Linkwings not only provides customers with a diverse range of products compliant with international standards such as UL, SAE, ISO, and MIL-Spec, but also offers customized crimping solutions tailored to specific application requirements. Whether you are in the automotive, industrial, medical, or renewable energy sectors, we can help you achieve the optimal connection solution through a systematic selection process and rigorous quality control.

Choosing Linkwings means not only selecting high-quality wire crimps but also choosing a reliable long-term partner.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In