Engine Wire Harness Manufacturer – Custom Engine Harness Solutions by Linkwings

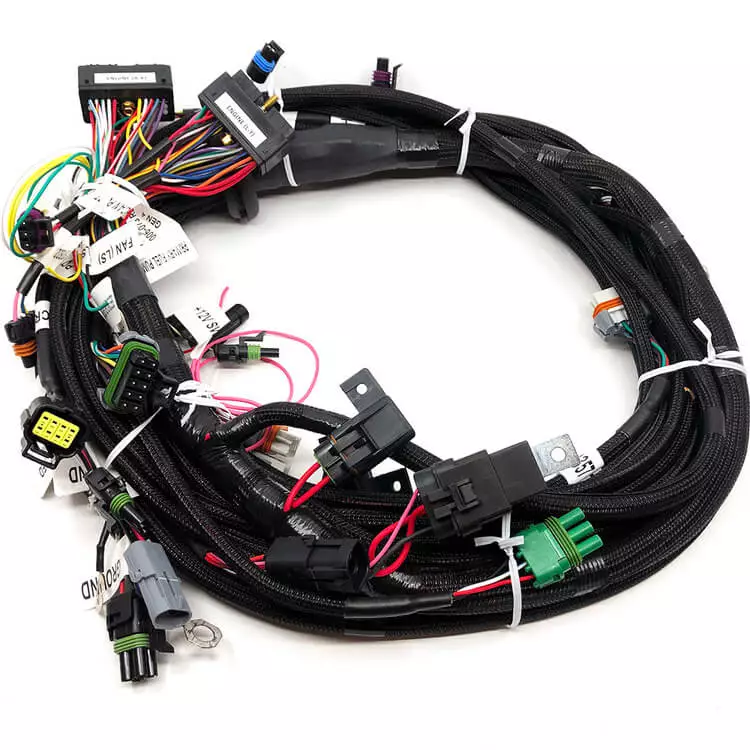

Engine Wire Harness is the core electrical system that connects the ECU, sensors, actuators and ignition system, and is the “nerve center” to ensure the reliable operation of the engine. As a professional Engine Wire Harness Manufacturer, Linkwings has mature production processes and customized development capabilities, supporting multiple types of engine project matching and rapid quotation services.

Engine Wire Harness Product Categories

Linkwings offers a full range of engine wiring harness solutions for different types of engines (gasoline, diesel, gaseous fuel), different applications (OEM, aftermarket, engineering equipment) and different system complexities. We support OEM/ODM, rapid prototyping and volume delivery.

EFI System Harness

Adaptation of sensors and actuators for Electronic Fuel Injection (EFI) systems.

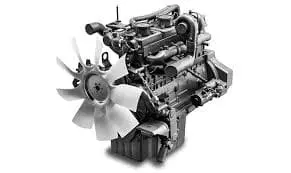

Diesel Engine Harness

Suitable for starter, solenoid valve, preheat plug and other control units in diesel engine systems.

Sub-System Sensor Harness

Provides connections primarily for unit modules in the engine subsystems

Heavy-Duty Engine Harness

Suitable for construction machinery, mining equipment, military vehicles and other harsh environments.

ECU-to-Engine Harness

Fully functional connection of the ECU (Engine Control Unit) to the engine body

CNG/LPG Engine Harness

Specialized control harnesses developed for natural gas and LPG engines

Custom Engine Harness

Customized development according to customer drawings, samples or functional requirements

Want a customized solution for your Wire harness business?

Whether you have a customization in mind or you’re not sure where to start, the wire harness experts at Linkwings have the right solution for you.

Technical Specifications & Manufacturing Capabilities

Linkwings has many years of experience in designing and manufacturing engine wiring harnesses, and has the ability to handle the whole process from raw material selection, process development to finished product testing. Our products can meet the electrical connection needs of different engine types such as gasoline, diesel, natural gas and so on. Therefore, they are widely used in automobile OEMs, powertrain system integrators, construction machinery manufacturers and other fields.

| Item | Specification Range |

|---|---|

| Conductor Material | Pure Copper / Tinned Copper |

| Wire Cross Section | 0.35mm² – 6.0mm² (Supports mix of signal & power circuits) |

| Operating Voltage | 12V / 24V / 48V (customized based on application) |

| Temperature Range | -40°C to +150°C (High-temp wires: Silicone / FEP / PTFE) |

| Jacket Materials | PVC / XLPE / TPE / PA66 / Braided Sleeve |

| Connector Types | TE, Delphi, Bosch, Sumitomo, Deutsch, JST (or equivalents) |

| Protection Rating | IP65 / IP67 / IP68 / IP69K |

| Tensile Strength | ≥150N (depending on structure and wire gauge) |

| Shielding Options | Aluminum Foil / Tinned Copper Braid / Dual Layer Shielding |

| Flame Retardant Rating | VW-1 / UL94V-0 / ISO 6722 |

| Labeling & Identification | Heat shrink labels / Barcode / UV print / Custom tags |

Typical Application Scenarios of Engine Wire Harness

Whether it is a traditional fuel engine or a new energy power system, the engine wiring harness is a key component to ensure the stable operation of the power output, energy efficiency management and electronic control system. Linkwings can provide wiring harness solutions that meet the requirements of structure, performance and working conditions according to different usage scenarios, and support OEM matching and customized development.

Passenger Car Engine System

For conventional fuel passenger cars (gasoline / diesel), connecting components such as ECU, ignition coil, fuel injector, sensors (e.g. oxygen sensor, temperature, pressure, throttle), etc., to ensure that the various functional modules of the engine work together efficiently. Higher requirements on plug precision, waterproof grade and heat resistance.

Commercial Vehicle and Truck Power System

Diesel engine system for medium and heavy trucks, logistics trucks, reefer trucks and so on. Often equipped with high current circuit, preheating control line, starter and solenoid valve control, need to have anti-vibration, oil resistance, dustproof characteristics, adapt to long time operation and complex road conditions.

Engine assembly for construction machinery

Widely used in excavators, loaders, bulldozers, road rollers and other engineering machinery equipment. This kind of engine wiring harness has complex structure, many branches, limited wiring space, and needs to have strong environmental adaptability, supporting IP67 or above protection level and high temperature anti-wear materials.

Genset / Industrial Power Equipment

It is used in diesel or gas generator sets, water pump sets, air compressors and other industrial power systems. The wiring harness is responsible for start-up control, sensing feedback, temperature control and protection, etc. It is often exposed to high temperature, high humidity or vibration working conditions, which requires strict requirements on wire durability and interface sealing.

Racing / Tuning Engine System

Serving racing or high-performance tuning car projects, the wiring harness needs to be adapted to the independent ECU system, supporting high-frequency signals, high-speed sampling and customized sensor interfaces. Emphasis is placed on harness weight control, compact branch design, EMI immunity and high precision plug selection.

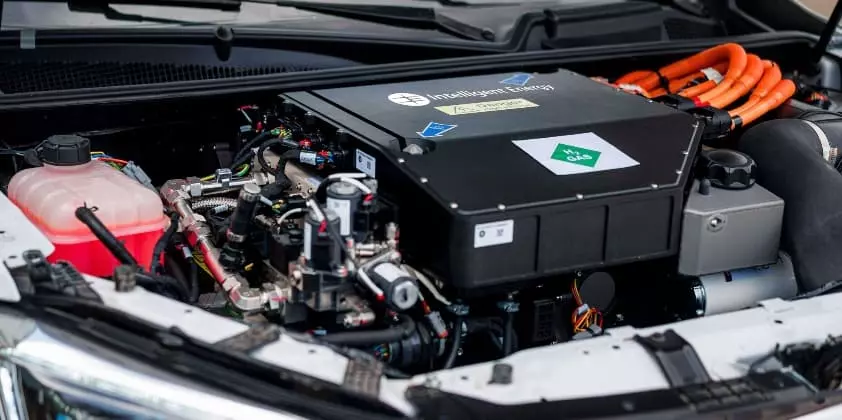

New Energy Hybrid Engine Module

Used for the connection between the engine and the electronic control module (such as engine management, start-stop control, thermal management) in the hybrid power system. It needs to be compatible with traditional engine signal lines and new energy CAN and LIN bus communication, with smarter and more integrated wiring harness design.

What is an Engine Wire Harness?

Engine Wire Harness is a special cable assembly used to connect various electronic components of the engine (such as ECU, sensors, ignition system, fuel injection system, solenoid valves, etc.) with the main control system of the vehicle. It is responsible for the transmission of signals and electricity, is the engine to achieve electronic control, performance regulation and data acquisition of the key carrier, often referred to as the engine’s “electrical central nervous system”.

Due to the complexity of the engine working environment, the engine wiring harness is usually equipped with high temperature resistance, oil resistance, waterproof, dustproof, anti-interference and other performance requirements. And the structural design is also more compact, need to be adapted to a number of branches and interfaces, to ensure that the systems work together efficiently.

Why the best engine wire harness is from China?

We understand that you have many choices when it comes to purchasing WIRE HARNESS. Here’s why savvy wire and cable professionals choose Linkwings.

10+ Years in Wiring Harness Manufacturing

Linkwings has over 10 years of experience in engine wiring harness manufacturing and is familiar with the structural requirements of gasoline, diesel and natural gas engines. Linkwings has served more than 300+ vehicle and powertrain projects, covering passenger cars, commercial vehicles, construction machinery and generator sets.

Support OEM / ODM customized development

We can flexibly customize the wire length, plug type, wire diameter combination, labeling, outer protection structure, etc. according to the drawings, samples or circuit requirements provided by customers. Accurately adapted to the ECU interface, engine wiring space and installation structure, supporting rapid prototyping and mass production.

High Reliability Manufacturing Standard

All engine wiring harnesses are protected by high temperature oil resistant wires, IP67+ waterproof plugs, braided or corrugated sheaths, with excellent heat, shock and dust resistance. Before leaving the factory, 100% of the products have passed the on-off test, tensile test and visual inspection, so the quality is stable and guaranteed.

Complete Engineering Support Services

Linkwings has an independent technical engineering team, which can provide services such as BOM optimization, connector substitution suggestions, 2D/3D drawing, and signage system planning. We help our customers to speed up project development, improve assembly efficiency, and save labor and cost.

Why Choose Linkwings as Your Engine Wire Harness Manufacturer

Choosing a professional engine wiring harness manufacturer is not only related to the quality of the product, but also determines the reliability and service life of the whole powertrain. Linkwings, as a senior enterprise specializing in wiring harness manufacturing, has a complete research and development system, mature manufacturing capabilities and rich industry experience in the field of engine wiring harnesses, which makes Linkwings your trustworthy long-term partner.

Linkwings has supplied high quality wire harnesses to more than 100 countries around the world and has earned a reputation as a one-stop shop for world-class wire harness solutions.

Whether you are an OEM, powertrain integrator or tuning engineer, Linkwings can provide you with professional, efficient and reliable engine wire harness solutions.

- Extensive experience in international trade

- Independent technical engineering team

- IATF 16949, ISO 9001 system certification

FAQs

1. What is the difference between engine wiring harness and general automotive wiring harness?

Engine wiring harnesses are mainly used inside the engine compartment and need to withstand higher temperature, vibration and oil environment. Compared with ordinary automotive wiring harnesses, engine wiring harnesses usually use high-temperature, oil-resistant and waterproof materials, with tighter plug connections, more compact structures, and more with shielding and enhanced protection.

2. Do you support engine harness customization? Can you produce according to drawings?

Yes, Linkwings can develop customized harnesses based on customer drawings, prototypes, or functional descriptions, including wire diameter, length, plugs, labels, and structural layouts, exactly to the customer’s system requirements. We can also assist you in optimizing the structure or recommend alternative terminal types.

3. Is the engine wiring harness water and heat resistant?

Yes. All of our engine wiring harnesses are made of high temperature resistant wires (such as silicone wires, XLPE), the plugs support IP67 or higher protection level, and the key connection parts are injection molded or heat-shrinkable encapsulated. Therefore, they can adapt to the high temperature, high humidity and high oil pollution environment in the engine compartment for a long time.

4. What are the main functional modules typically included in an engine wiring harness?

Engine harnesses typically include the following interfaces: ignition coil, injectors, water temperature sensor, oil pressure sensor, oxygen sensor, throttle, ECU main connector, starter, solenoids, etc. The structure may vary depending on the engine model and control system design. The structure may vary depending on the engine model and control system design.