Flat Cable vs Round Cable: Which Cable is Better for You?

Home » Flat Cable vs Round Cable: Which Cable is Better for You?

In electronic and industrial applications, flat cables vs round cables remains a common consideration for engineers and procurement personnel during selection. As the two most prevalent cable configurations, they each offer distinct advantages and disadvantages in terms of space utilization, signal performance, mechanical strength, and suitability for specific scenarios. Understanding their differences and respective strengths not only helps designers optimize cabling solutions but also ensures equipment maintains stable and efficient operation over extended periods.

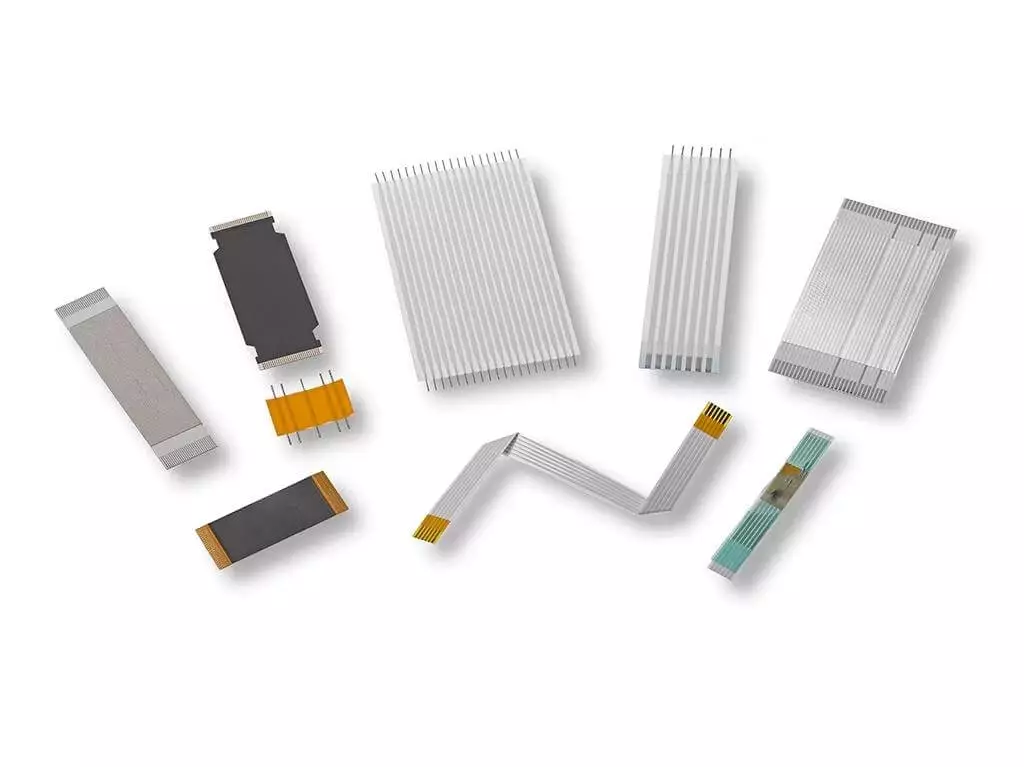

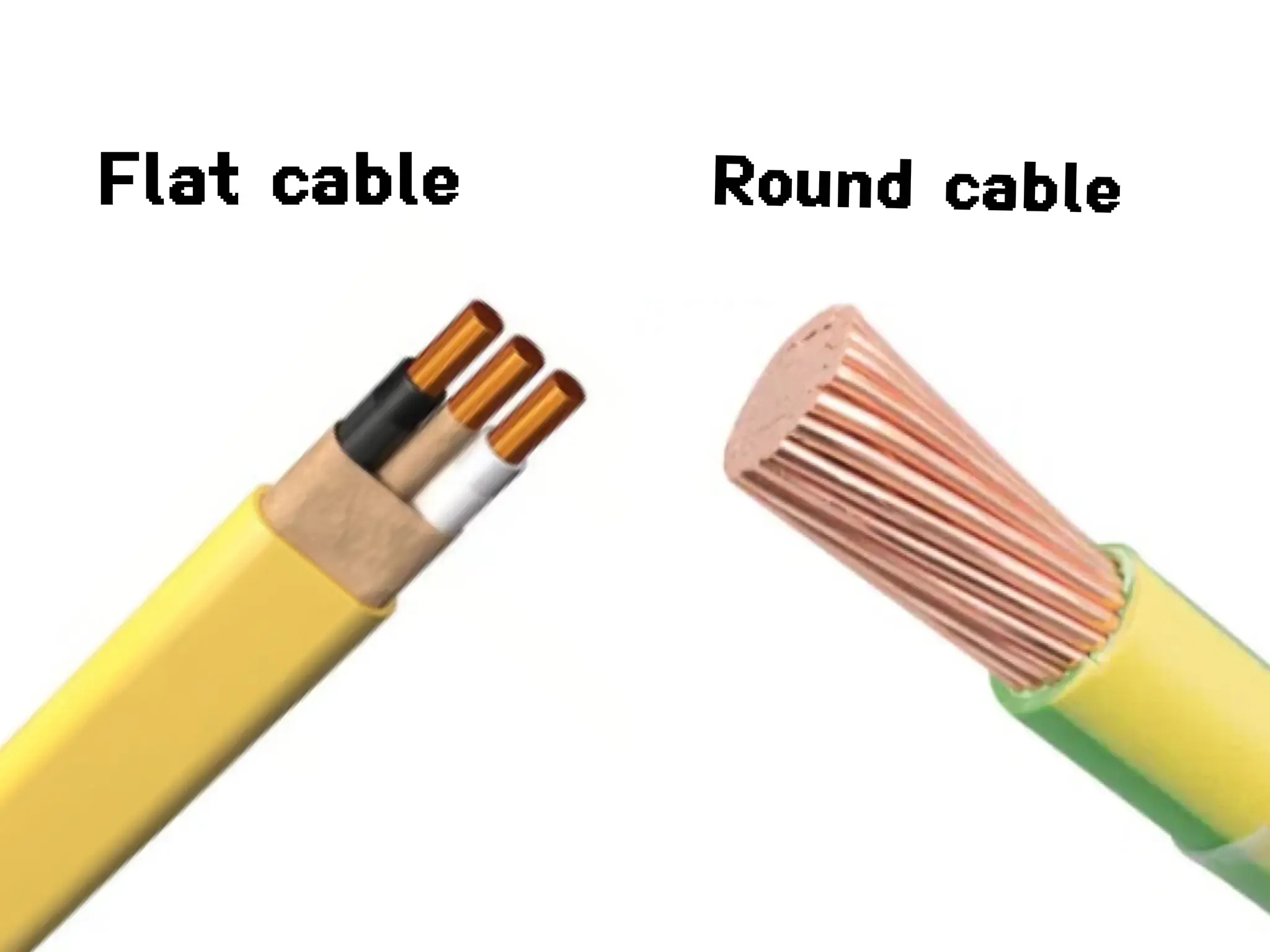

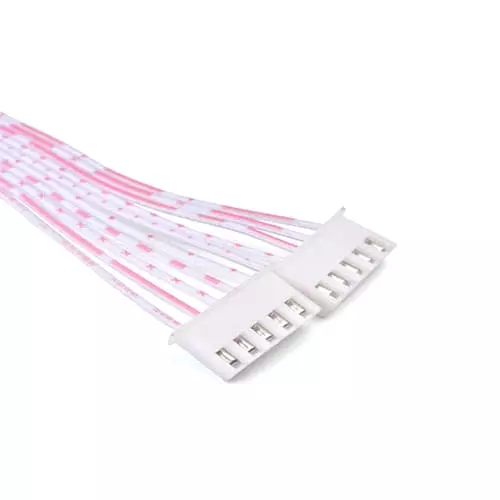

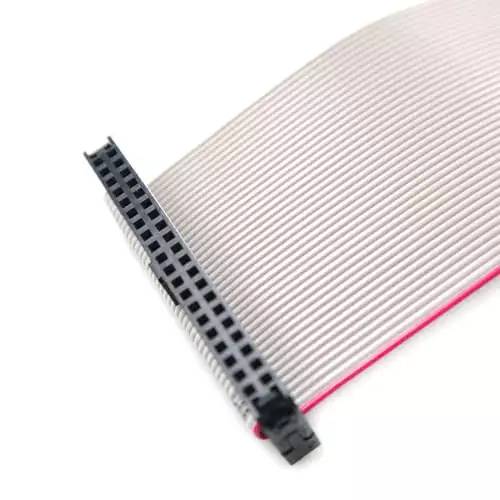

Flat cable consists of multiple conductors arranged in parallel and enclosed within a single insulating layer to form a ribbon-like cable. Its compact structure and flat profile make it more suitable for routing in confined spaces compared to traditional round cables. Due to the orderly arrangement of conductors, flat cable maintains consistent electrical performance while offering lightweight advantages. It is commonly used in electronic and industrial equipment with stringent space and routing requirements.

Key characteristics include thinness, flexibility, space efficiency, and ease of routing, meeting modern demands for miniaturization and high-density configurations. Common conductor pitch standards—0.5mm, 1.0mm, 1.25mm, and 2.54mm—ensure broad compatibility with various connectors. From consumer electronics to industrial control systems, flat cables deliver a reliable and efficient cabling solution.

What is a Round Cable?

Round Cable is a cable type formed by arranging multiple conductors in a bundled structure, then sequentially encasing them with insulation, shielding, and an outer jacket. Unlike flat ribbon cables, Round Cable features a symmetrical circular cross-section. This design not only provides superior mechanical strength but also enhances electromagnetic interference (EMI) resistance through its shielding layer, ensuring more stable performance in complex electrical environments.

The standout advantages of Round Cable lie in its durability and versatility. Its outer sheath effectively resists mechanical abrasion, tension, and environmental factors while supporting long-distance transmission. Offering flexible configurations such as twisted pairs, braided shielding, or foil shielding, Round Cable finds extensive applications in data communication (e.g., USB, LAN), power transmission, industrial automation, and outdoor cabling. It serves as the preferred solution for applications demanding high reliability and environmental adaptability.

Flat Cable vs Round Cable

| Comparison Aspect | Flat Cable | Round Cable |

|---|---|---|

| Space Efficiency | Flat design, compact, ideal for high-density routing | Bulkier, requires more routing space |

| Flexibility & Routing | Highly flexible, easy to bend, suitable for tight spaces or dynamic connections | More durable under repeated bending, but less flexible in layout |

| Electrical Performance | Parallel conductors, consistent signal paths, low crosstalk | Supports twisted pairs and shielding, stronger EMI protection |

| Heat Dissipation | Larger surface area, better heat dissipation | Relatively weaker, relies on insulation and shielding |

| Mechanical Strength | Lower tensile strength, less suitable for harsh environments | Strong tensile and abrasion resistance, ideal for industrial/outdoor use |

| Weight | Lightweight, suitable for portable devices | Heavier, not ideal for weight-sensitive designs |

| Cost | Simple structure, lower manufacturing cost | More complex, shielding and jackets increase cost |

| Typical Applications | Laptops, cameras, car infotainment, medical devices, industrial modules | USB, LAN, power cables, industrial automation, outdoor communication wiring |

Advantages and Limitations of Flat Cable

Advantages

- Space-saving: Flat cable features a ribbon structure with parallel conductors, offering greater compactness than round cables and enabling high-density wiring within confined equipment spaces.

- High flexibility: Excellent bending performance makes it suitable for applications requiring repeated opening/closing or dynamic connections, such as laptop hinges or automotive center consoles.

- Simplified Wiring: Neatly arranged conductors allow simultaneous connection of multiple wires during installation, boosting assembly efficiency.

- Strong Signal Consistency: Uniform conductor path lengths minimize impedance mismatch and signal crosstalk, enhancing transmission quality.

- Lightweight: Lighter than round cables, making it suitable for portable or mobile devices requiring weight reduction.

Limitations

- Insufficient mechanical strength: Weaker tensile and abrasion resistance, unsuitable for harsh industrial or outdoor environments.

- Limited current capacity: Most flat cables have smaller cross-sectional areas, making them unsuitable for high-power transmission.

- Reduced durability: Reliability may be inferior to round cables under prolonged vibration or high mechanical stress.

- Poor environmental adaptability: Additional protective measures are required in high-humidity, high-temperature, or strong electromagnetic interference environments.

Advantages and Limitations of Round Cable

Advantages

- High Mechanical Strength: The circular structure provides superior tensile, compressive, and torsional resistance, enabling it to withstand frequent bending and harsh operating conditions.

- Exceptional Durability: The outer jacket and multi-layer insulation structure enhance abrasion resistance and protective capabilities, making it suitable for long-term use.

- Superior Shielding Performance: Often equipped with braided or foil shielding, it effectively blocks electromagnetic interference (EMI) and ensures signal integrity.

- High Current and Power Handling: Capable of supporting conductors with larger cross-sectional areas, making it ideal for power supply and high-power applications.

- Versatile adaptability: Suitable for diverse environments including long-distance transmission, industrial automation, and outdoor communications.

Limitations

- Space-consuming: The circular structure is less compact than flat cables in confined equipment interiors, resulting in lower routing efficiency.

- Heavier weight: Compared to flat cables, round cables are bulkier and unsuitable for weight-sensitive portable devices.

- Limited routing flexibility: Round cables are less adaptable than flat cables for tight equipment layouts, restricting routing paths.

- Higher manufacturing and cost: Due to more complex construction—especially in shielded or multi-layer jacketed products—costs typically exceed standardized flat cables.

Flat cable vs round cable: How to Choose Cable for Your Applications?

1) Consumer Electronics and Portable Devices

Typical Applications: Notebook/tablet display modules, camera modules, printer scan heads, internal connections for wearable devices.

Suitable Conditions: Short distances within devices, extremely compact spaces, requiring lightweight and high-density wiring, mass assembly.

Key Parameters

- Pitch: Commonly 0.5/0.8/1.0/1.25mm; typical length ≤300mm.

- Bending: Static ≥10× thickness; Dynamic ≥20× thickness (empirical value), prioritize “U”-shape/large radius bending.

- Interface: ZIF/LIF connectors, recommended with pull-tab and adhesive stress relief.

- Material: PET/PI laminated film; requires UL94V-0 flame retardancy, RoHS/REACH compliance.

Common Failure Points and Countermeasures - Crease Cracking → Avoid sharp-angle bends; select high-flex formulations/add bend reinforcement.

- Pad/Latch Damage → Add rigid stiffeners at ends; specify insertion/extraction force.

- EMI leakage → Select FFC/FPC with ground reference/shielding; optimize trace return paths.

Linkwings Recommendations

- Standard FFC (0.5/1.0/1.25mm), optional gold fingers/tin plating, pull tabs, stiffeners.

- Ultra-thin FPC, supports 3D routing and localized thickening, suitable for camera/hinge areas.

2) Automotive Electronics and Central Control Systems

Typical Applications: Central control displays, instrument panels, infotainment systems, and internal interconnects for ADAS sensors.

Suitability Requirements: Wide temperature range (-40 to +85/105 °C), vibration and shock resistance, stringent EMI compliance, and extended lifespan.

Key Parameters

Key Parameters

- Signal: Differential signals (LVDS/MIPI/PCIe, etc.) requiring controlled impedance and low crosstalk.

- Shielding: Shielded FFC/FPC or shield layer + reference ground design; prioritize 360° contact for ground terminals.

- Mechanical: Vibration-resistant mounting point design; bend zones avoiding hardware interference; stress relief added to ports.

- Standards: Compliant with ISO 16750 (Road Vehicle Environmental Conditions) and other automotive environmental stress requirements.

Common Failure Points & Countermeasures - Loose Contact/Wear → Terminal locking structures, secondary fixation, vibration-resistant adhesive.

- EMI Overlimit → 360° shield overlap at termination points, ground spring/EMI gasket coordination.

Linkwings Recommendations

- Shielded high-speed FFC/FPC (controlled impedance) with automotive-grade material selection and termination solutions.

- Hybrid Solution: FFC/FPC for internal display/camera applications, shielded round wire for external harness sections crossing the vehicle body.

3) Industrial Automation and Equipment Control

Typical Applications: PLCs, robots, cable chain routing, servo/encoders, factory interconnects.

Suitable Conditions: Oil contamination, dust, repeated bending and dragging cycles, high interference density, long-distance routing.

Key Parameters

- Jacket: PUR/TPU (abrasion-resistant, oil-resistant, low-temperature flexibility); UV-resistant option for outdoor use.

- Mechanical: Cable chain rating; static bend radius ≥7.5×OD, dynamic ≥15×OD (empirical values).

- EMI: ≥80–90% braided shielding + foil shielding overlay, 360° shield crimping at ends.

- Environment: IP rating, chemical resistance, flame retardancy (e.g., UL 94V-0).

Common Failure Points & Countermeasures - Jacket wear/cracking → Select PUR, ensure proper routing radius and drag chain guidance.

- Interference/packet loss → Dual shielding, independent grounding, layered routing (power/signal separation).

Linkwings Recommendations

- Industrial-grade shielded round cable (twisted pair + braided/foil shielding, PUR jacket), with optional drag chain/twist resistance ratings.

- Custom harnesses (terminal crimping, bundling with identification tubes, overmolding/injection molding, integrated connectors).

4) Communication and Data Transmission

Typical Applications: USB/HDMI/DP, Ethernet, 5G small cells, high-speed interconnects within chassis.

Suitable Conditions: High bandwidth, low jitter, strict control of return loss and insertion loss, strong interference resistance.

Key Parameters

- Structure: External connections prefer shielded round cables (twisted pairs, Foil+Braid composite shielding).

- Controlled Impedance: Differential 85/90/100 Ω common; single-ended typically 50 Ω.

- Internal Short-Distance: High-speed shielded FFC/FPC optional for in-chassis/module-to-module connections, with controllable length and short loop paths.

- Termination: 360° shield termination, metal housing connectors, continuous ground return paths.

- Common Failure Points & Countermeasures

- Insufficient eye margin/EMI → Optimize cable length and routing; add reference ground and termination matching.

- Mismatched connectors → Strictly control crimp height; conduct impedance probe sampling.

Linkwings Recommendations

- High-speed shielded round cables (USB 3.x, HDMI, Ethernet Cat5e/6/6A customizable).

- High-speed controlled impedance FFC/FPC (for short-distance high-speed interconnects within equipment).

5) Power Supply and High-Current Applications

Typical Applications: Power distribution, energy storage/renewable battery modules, inverters, industrial power backplanes.

Suitability Criteria: High current, low voltage drop, thermal management, creepage and clearance meeting safety standards.

Key Parameters

- Conductor: Larger cross-sectional area (AWG cross-section/stranded/flat copper bus), focusing on temperature rise and voltage drop.

- Thermal: I²R heating → Cross-sectional area selection and heat dissipation paths (copper cladding, ventilation, thermal interface materials).

- Insulation: Temperature/chemical resistance, meeting creepage distance and clearance requirements (based on system voltage level).

- Connections: Crimp terminals/high-current blades, bolted connections, stress relief at terminals.

Design Recommendations - Perform temperature rise and voltage drop calculations. Derive cross-sectional area and number of parallel strands based on target temperature rise (e.g., ΔT 10–30 °C).

- For high-frequency/pulsed currents, account for skin effect and contact resistance.

Linkwings Recommendations

- High-current round cables/multi-core power cables (optional silicone rubber/PVC/PUR jackets).

- Flat copper busbars/flexible copper busbars (FLEX BUSBAR) and custom power harnesses (molded, anti-loosening, labeled).

FAQs

Q1: Which cable is more suitable for high-speed signal transmission?

A1: For short-distance high-speed transmission within devices (e.g., display modules, camera modules), shielded flat cables offer better performance. For long-distance transmission or complex electromagnetic environments, round cables with twisted pairs and shielding provide superior signal integrity.

Q2: Can flat cables be used for power transmission?

A2: Generally, flat cables are better suited for low-current applications and are less ideal for high-power transmission. However, in certain customized designs (such as flexible copper busbars or custom high-current flat cables), they can also be used for power distribution. For high-current scenarios, round cables or flexible copper busbars offer greater reliability.

Q3: Is Round Cable more durable?

A3: Yes. Round cable offers superior mechanical strength and abrasion resistance compared to flat cable. It performs more reliably under vibration, tension, or outdoor conditions. Consequently, it is widely adopted in industrial automation, power transmission, and telecommunications applications.

Conclusion

In engineering design and equipment manufacturing, the choice between flat cable vs round cable is not inherently superior or inferior; it depends entirely on specific application requirements.

- Flat cable is renowned for its thin profile, excellent flexibility, and space-saving properties, making it ideal for scenarios demanding compact wiring and lightweight solutions—such as consumer electronics, automotive displays, and medical instruments.

- Round Cable excels in industrial automation, power transmission, long-distance data communication, and outdoor environments due to its high mechanical strength, superior shielding performance, and greater current-carrying capacity.

Therefore, when selecting cables for actual applications, comprehensive consideration should be given to space constraints, electrical performance, environmental conditions, assembly methods, and cost factors to ensure long-term stable operation in the target application. As a cable and wire harness manufacturer with over 15 years of experience, Linkwings not only provides standardized Flat Cables and Round Cables but also offers high-performance, customized solutions tailored to specific customer requirements.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In