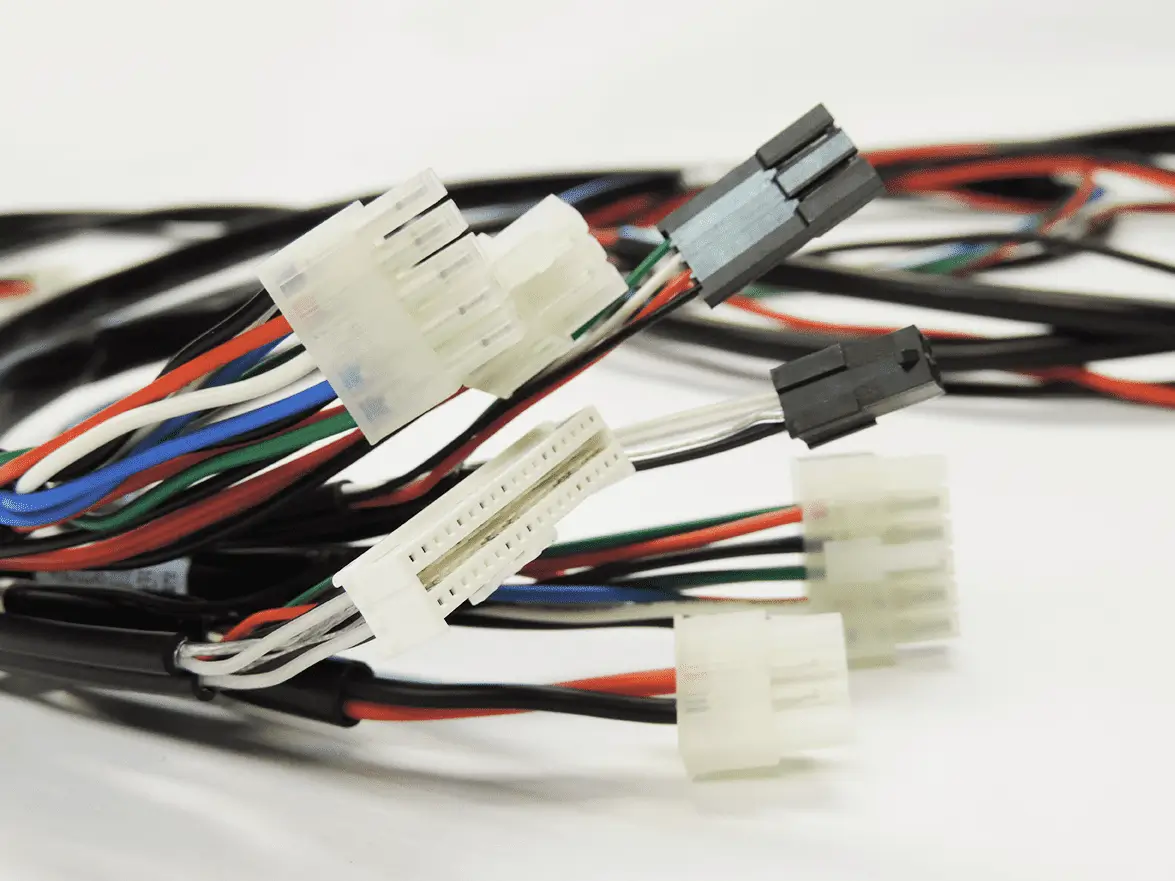

industrial wire harness manufacturer

Linkwings is a trusted industrial wire harness manufacturer specializing in providing high-performance, customizable wire harness solutions for industrial customers worldwide. We are deeply involved in the fields of industrial automation, energy, rail transportation, and medical equipment, and possess comprehensive technical capabilities covering the entire process from design and manufacturing to testing.

About Linkwings — Your Trusted Industrial Wire Harness Manufacturer Partner

Linkwings specializes in the research, development, design, and production of industrial wire harnesses and cable assemblies, serving industries such as automation equipment, energy and power, rail transportation, medical instruments, and shipbuilding. With over a decade of manufacturing experience and global customer service capabilities, we have grown to become a trusted industrial wire harness manufacturer in the industry.

Manufacturing and Design Capabilities

- In-house Factory: Equipped with modern production facilities and automated equipment.

- Professional Team: Capable of handling the entire process from design to mass production.

- Customization Capabilities: Able to provide customized wiring harness solutions according to customer requirements.

Quality and Certification Assurance

- Strictly adheres to quality management systems such as ISO9001 and IATF16949

- Products comply with international standards such as UL, CSA, and IEC

- Compliant with environmental regulations including RoHS, REACH, and low smoke, halogen-free requirements

Linkwings Industrial Cable Harness Solutions

Linkwings industrial wiring harness products are designed to provide safe, reliable, and efficient electrical connection solutions for a variety of complex and demanding industrial environments. Whether it’s power transmission, low-voltage control signals, or high-speed data, we can customize wiring harness assemblies to meet our customers’ system requirements.

High reliability design

- Stability: Uses high-purity oxygen-free copper (OFC) or tin-plated copper conductors to ensure low resistance and high conductivity.

- High Environmental Adaptability: Optional high-temperature resistant (-60°C to +200°C), oil-resistant, corrosion-resistant, and UV-resistant jacket materials, such as XLPE, PUR, silicone, and fluoroplastics (FEP/PTFE).

- High Protection Rating: Achieves IP67, IP68, or even IP69K waterproof and dustproof performance, suitable for outdoor, humid, dusty, and other harsh environments.

Multi-type application coverage

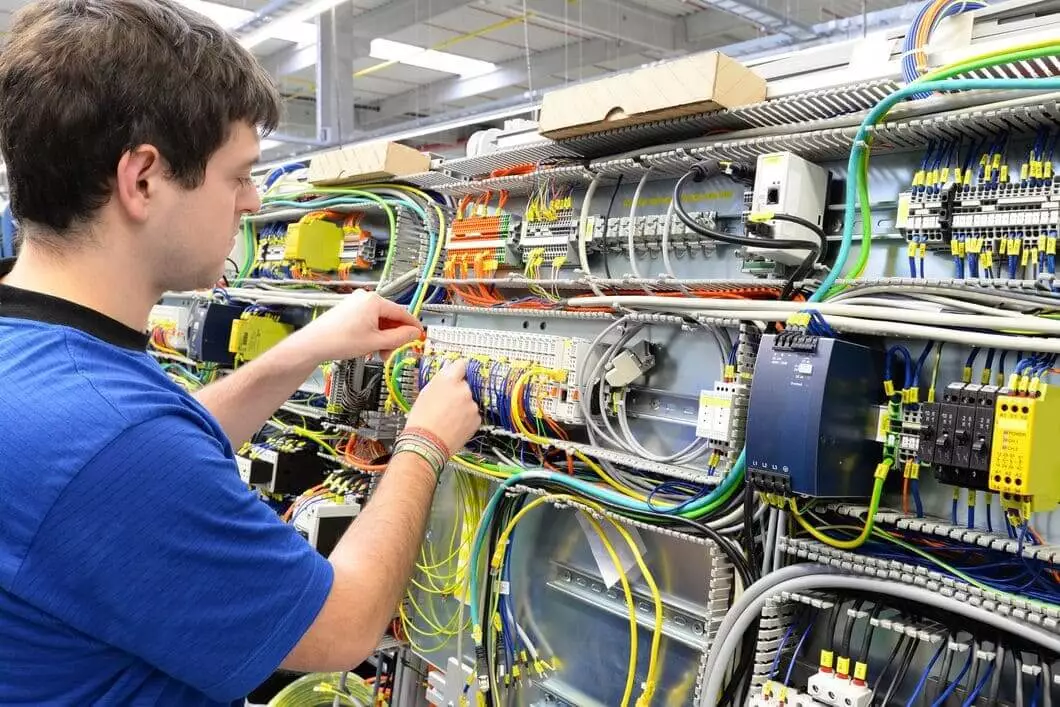

- Power transmission harnesses: Suitable for high-power equipment, industrial motors, electrical control cabinets, and other scenarios.

- Control and signal harnesses: Provide accurate and stable signal transmission for PLCs, sensors, control panels, and other devices.

- High-speed communication harnesses: Support industrial Ethernet, CAN bus, RS485, and other data transmission standards.

- Highly flexible drag chain harnesses: Maintain long-term stability in high-bending applications such as automated production lines and robotic arms.

Strong customization capabilities

- Flexible configuration: Customize wire diameter, length, color, terminal type, sheath marking, shielding structure, etc. according to customer requirements.

- Integrated hybrid functions: Supports the integration of power lines, signal lines, and data lines into a single cable harness to simplify wiring and reduce installation costs.

- Structural optimization: Ensure reasonable wiring within the equipment space and reduce wear through 3D cable harness design and wiring simulation.

Strict quality control

- Full testing, including continuity, insulation resistance, withstand voltage, tensile strength, bending, weather resistance, etc.

- Automated production processes combined with manual inspection to ensure batch consistency and reliability

- Strict adherence to international standards to ensure long-term safe and stable operation

Engineering & Quality Control

Design phase

Electrical requirements analysis → 3D wiring harness modeling → BOM confirmation

Production phase

Automated wire cutting, terminal crimping, welding, injection molding, waterproof sealing

Testing phase

Continuity testing, pressure testing, tensile testing, insulation resistance, bending resistance testing