IP67/IP68 Waterproof Connector Cable Solutions

Linkwings is a specialist waterproof connector cable manufacturer. We can provide high quality customised waterproof connector cable solutions. Our products are widely used in harsh environments such as outdoor lighting, industrial automation, underwater equipment, and new energy systems.

Custom Waterproof Connector Cable from Connector Cable Manufacturer

Linkwings is a professional connector cable manufacturer specializing in providing high quality customized waterproof connector cable solutions. Our products are widely used in outdoor lighting, industrial automation, underwater equipment, new energy systems and other harsh environments. We provide one-stop service from structural design, material selection to finished product assembly, support IP67/IP68 high protection level, and meet a wide range of voltages, currents and cores.

Whether you need standard connectors such as M8, M12, M16 or M23, or special lengths, colors, jacket materials or terminal forms, we can respond flexibly and deliver quickly. All products comply with CE, RoHS, UL and other international certification standards to ensure stable electrical performance, safety and reliability, is your ideal choice for connection solutions in complex applications.

what is a Waterproof Connector Cable?

Waterproof connector cables are cable assemblies designed to prevent water penetration. It is typically used in harsh environments or in electrical and electronic systems that require waterproof protection. It consists of a combination of cable and mating waterproof connector to ensure that electrical connections remain safe and reliable in wet, rainy, underwater or splashy conditions.

Linkwings waterproof connector cable has excellent waterproof, dustproof and mechanical resistance, fully meets the IP67/IP68 protection standard, and is suitable for a wide range of equipment connection needs.

Characteristics of waterproof connector cables

The core advantages of waterproof connector cables are mainly in their reliability, safety, environmental adaptability and wide application compatibility.

- High protection class (IP67/IP68)

- Stable plugging and unplugging, reliable connection

- Low contact resistance / high conductive efficiency

- Corrosion-resistant, oil-resistant, UV-resistant materials

- Various specifications available: 2~12 core, M12/M16/M23 and other interfaces

- Quick installation, support customization

Types of Waterproof connector cables

As the world’s leading connector cable manufacturer and supplier, Linkwings can provide many types of waterproof connector cable, besides, we also provide customized interface, color, material, voltage service.

Waterproof Connector Cable – Technical Parameter Comparison & Selection Table

Below is a detailed international common waterproof connector cable technical parameters comparison table / selection form template. You can replace the content according to your actual needs, the table has taken into account the common specifications (such as M8, M12, M16, M23) with common parameters.

| Parameter | M8 Series | M12 Series | M16 Series | M23 Series |

|---|---|---|---|---|

| Connector Type | Threaded coupling | Threaded / Snap-lock | Threaded coupling | Threaded coupling |

| Number of Pins | 3 / 4 / 5 / 6 / 8 | 3 / 4 / 5 / 8 / 12 | 2 / 4 / 5 / 7 / 9 | 6 / 8 / 12 / 19 |

| Rated Voltage | 30V / 60V | 250V / 300V | 250V / 500V | 400V / 600V |

| Rated Current | 1–3 A | 2–5 A | 5–10 A | 10–20 A |

| Ingress Protection | IP67 | IP67 / IP68 | IP67 / IP68 | IP68 |

| Operating Temp. Range | -20°C ~ +80°C | -25°C ~ +85°C | -25°C ~ +90°C | -40°C ~ +105°C |

| Housing Material | PA66 / Nickel-plated Brass | Zinc Alloy / Ni-Plated Brass | Ni-Plated Brass / Stainless Steel | Ni-Plated Brass / Stainless Steel |

| Insulation Material | TPU / PVC / PUR | TPU / PVC / PUR | TPU / PUR | PUR / Special Polymers |

| Cable OD Range | 4–6 mm | 4–8 mm | 6–10 mm | 8–12 mm |

| Termination Type | Solder / Crimp / Screw | Solder / Crimp | Crimp / Solder | Crimp / Solder |

| Cable Orientation | Straight / Right-angle | Straight / Right-angle | Straight / Right-angle | Straight / Right-angle |

| Typical Applications | Sensors / Signal lines | Automation / Power lines | Motor control / Solar PV | Heavy-duty motors / Robotics |

Additional selection notes:

- If used for low voltage signal control system → M8/M12, 3~5 core, rated current <5A is recommended.

- For power supply (e.g. LED light/pump power) → M12/M16, 5~8 cores, voltage ≥250V are recommended.

- If high load power supply or motor control is required → M23, 12~19 cores, high current support is recommended.

- For long-term outdoor/underwater applications → IP68 + PUR jacket material is preferred for better weather resistance.

If you provide me with a specific model number or product range, I can provide you with a more precise solution for waterproof connector cable. Please contact the technical team at Linkwings!

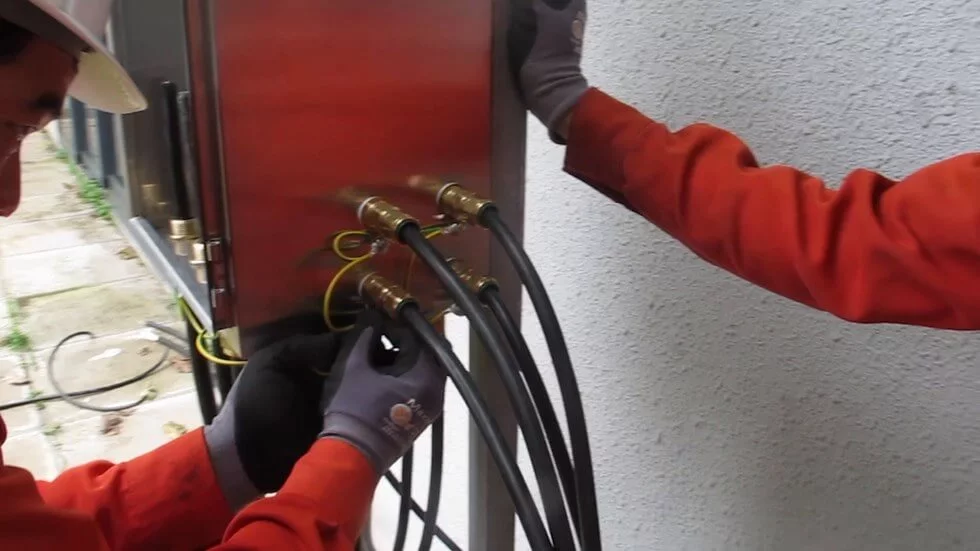

waterproof connector cable applications

Waterproof connector cables are used in a variety of industries. If you are making a selection for a specific project or industry, you can contact us for further information on matching models, connector configurations or wire types.

Waterproof connector cable is commonly used in LED street light, landscape light, tunnel light, garden light and so on. These outdoor applications require a cable with high protection level (IP67/IP68), UV resistant jacket and quick plug and play installation. Common specifications include M12/M16 connector, 3~5 cores, PVC/PUR jacket.

Sensors, encoders, PLC, solenoid valves, servo systems use waterproof connector cable. It can provide anti-interference design (shielding) and high mechanical strength, and support fast connection. Common specifications are M8/M12, 3~8 cores, TPU jacket with shield.

Sewage pumps, submersible pumps, water purification equipment, automatic irrigation systems need waterproof connector cable with IP68 level waterproof. In addition to this, the cable should also use materials with high corrosion resistance, voltage resistance and electrical insulation performance. Common specifications include M16/M23, 2~4 cores, high current support.

The applications of waterproof connector cable on PV system include solar module connection, panel lead wire, inverter interface, etc. With IP67+ protection, it can effectively prevent dust and rainwater intrusion. And different cable lengths and stringing solutions can be customized according to actual applications. Common specifications are M12 / MC4 compatible connectors, double sheathed, weather resistant.

Radar, navigation lights, underwater cameras, and deck power systems are also common applications for waterproof connector cables. cables provide a high level of waterproofing and salt spray corrosion resistance, and its construction is designed from the ground up to be vibration and shock resistant. Common specifications: M23, IP68 stainless steel housing with adhesive encapsulation.

With the development of electric vehicles, EV battery management systems, charging piles, and control modules also make extensive use of waterproof connector cable.Linkwings’ cable can provide high power transmission support (high current), high frequency plugging and unplugging life and dustproof and waterproof performance against arc breakdown. Common specifications: customized plugs, M16/M23, 5~10 cores, high temperature wire.

How do we control the quality of your waterproof connector cable?

In order to ensure the quality of waterproof connector cable, our production process is strictly controlled in five aspects: raw material, design structure, manufacturing process, testing and verification, and quality management system.

Linkwings’ waterproof cable is designed according to IEC 60529 protection class. In addition, our factory is equipped with multiple automatic soldering machines, laser wire stripping equipment, and epoxy or PU sealing of the connection ends. Each process is equipped with testing procedures (e.g. conductivity test, dimensional test, preliminary waterproof performance inspection).

custom waterproof connector cable from manufacturer

In the design and production of Waterproof Connector Cable, customization is the key to meet the needs of different industries and applications, Linkwings can provide a variety of customization options, from the appearance of the structure to the electrical performance, the following is a classification of common customization points and detailed description.

Custom Interface Type

As a professional manufacturer of waterproof connector cable, Linkwings can provide customized interface service. Common connector specifications include M5, M8, M12, M16, M23, 7/8″, RJ45, USB, DC plugs and so on. In addition to this, the interface shape, connection method and number of pins can also be customized.

Custom Cable Construction

The common specifications of the number of cores and cross-sectional area of waterproof connector cable are as follows: 2×0.5mm², 4×1.0mm², 5×2.5mm², etc., and single twisted, shielded/unshielded are available. The sheath material can be PVC, TPU / PUR and rubber sheath. Sheath colors are available in black, grey, orange, blue, etc., and can also be customized with brand-specific colors.

Custom Length and Outlet Direction

Cable lengths from 0.2 meters to over 50 meters can be customized as needed. Single/double head design is available. Outlet direction can be customized vertically, laterally, 180° steering, etc.

Custom Electrical Performance

- Rated voltage/current: common support 30V600V, 1A20A

- Withstand voltage/insulation level: customized high-voltage test level, such as 1500V, 2000V

- Signal type support: analog signal, digital signal, Ethernet, CAN, RS485, etc.

What level of protection do your waterproof connector cables support? Is it IP67 or IP68?

We offer a variety of protection ratings, including IP65, IP67 and IP68, depending on the connector construction and application scenario. the IP68 version supports short and even long term submerged operation, and is suitable for high humidity scenarios such as pumps, submersible monitoring, and so on.

What voltage and current do these cables support?

Depending on the model, the rated voltage ranges from 30V to 600V and the rated current from 1A to 20A. Typical examples are M12 connector cables with 250V/4A and M23 high power models up to 600V/20A.

Is it possible to customize the cable length, number of cores and interface type?

We support all series of customization service! We support Full range of customized services, including wire length, number of cores (2~19 cores), jacket material (PVC/TPU/PUR), interface specification (M8/M12/M16/M23), etc. We can also provide OEM/ODM services.

What certifications have your products passed?

Our waterproof connector cables can pass or meet the following certification standards:

- ce, rohs, ul, tv

- IP67/IP68 test

- Special occasions can provide Fire prevention, flame retardant, REACH, salt spray test report

What is the insertion and extraction life and mechanical strength?

Linkwings’ waterproof connector cable has a plug life of >10,000 cycles. The pins are gold/silver plated for corrosion resistance and electrical stability. The cable jacket has high tensile strength and is suitable for frequent movement or vibration.

Do you provide samples? What is the typical delivery time?

We can provide free samples of some models for testing. Delivery time for standard products is 3~7 working days, customized products are usually 7~15 days depending on the complexity.

Can the cable be used underwater? What is the water depth limit?

IP68 series products support underwater use, the specific depth and time of water resistance should be confirmed according to the connector structure and injection process. We have products can be used underwater 1~10 meters, please contact technical support for detailed parameters.

Is it compatible with other brands of connectors (e.g. Phoenix, TE, Binder)?

Some interfaces (e.g. M8, M12) follow international standards and are cross-brand compatible. Customization can be matched or adapted according to your target system selection.