Home » LVDS Wire Harness Manufacturer

LVDS Wire Harness Manufacturer | High-Speed Signal Cable Assemblies

Linkwings is a professional LVDS wire harnesses manufacturer for automotive displays, industrial cameras, and high-speed data modules. Full EMI shielding, custom length, connectors & assembly.

Get Custom LVDs Wire Harness From Manufacturer

Linkwings is a manufacturer specializing in high-speed signal transmission cable solutions, with over a decade of experience in LVDS (Low Voltage Differential Signaling) cable design and assembly. Our services cater to high-reliability sectors such as automotive electronics, industrial vision systems, medical imaging equipment, and edge computing modules. We are well-versed in mainstream high-speed signal interface protocols such as FPD-Link, V-by-One, eDP, and MIPI, and possess extensive engineering expertise and connector compatibility capabilities, enabling us to swiftly address the customized requirements of OEMs and R&D clients.

In the LVDS cable assembly field, Linkwings offers one-stop engineering support capabilities, including structural modeling, wire pair twist matching, EMI/EMC shielding design, and multi-brand connector selection (such as I-PEX, JAE, Molex, and TE). We offer ±0.5mm precision in wire length control, 100% continuity and signal integrity testing, ensuring the electrical stability and mechanical reliability of each harness in high-speed environments. We are your trusted professional partner in the field of high-speed differential connections.

LVDS Wire Harness Series

Linkwings offers a wide range of LVDS (Low Voltage Differential Signaling) cable assemblies, which are widely used in high-speed video transmission, image processing, embedded systems, and in-vehicle vision modules. We support the development of a full range of products, from single-pair LVDS to multi-pair high-frequency signal buses, and can optimize shielding, twist pitch, impedance matching, and connector structure based on customers’ system architecture and electromagnetic compatibility requirements to achieve high-reliability high-speed transmission. Below are our main LVDS cable assembly product types and their respective features.

Single-channel LVDS harness

- Suitable for point-to-point high-speed transmission in single-camera, single-screen display, sensor module, and other applications.

- Features 1 pair of differential signal lines + power line, with optional shielded line structure.

- Compact structure, suitable for space-constrained scenarios, with transmission rates up to hundreds of Mbps.

Typical interface support: FI-R (JAE), I-PEX 20453, DF13, JST 1.25, etc.

Multi-channel LVDS Harness

- Supports 2 pairs, 4 pairs, 6 pairs, or 8 pairs of differential signal lines, suitable for high-definition video or high-speed data parallel transmission;

- Shielding between pairs ensures low crosstalk and excellent signal integrity;

- Suitable for industrial vision systems, LCD control modules, large-screen displays, GPU interface expansion, and more.

Typical applications: displays at 1920×1080 @60Hz or higher, FPGA data transmission.

Automotive FPD-Link Harness

- Specifically designed for in-vehicle cameras, surround view systems, AR HUDs, lidar modules, and other applications;

- Supports FPD-Link III, GVIF, GMSL, and SerDes protocols, compliant with AEC-Q100 electrical standards;

- Features high-flexibility shielded cables, IP-rated connectors, and consistent crimping control for terminals.

Connector brands supported: I-PEX, Rosenberger, JAE, Yazaki, Aptiv, etc.

Industrial & Medical LVDS Harness

Industrial & Medical LVDS Harness

- Used for high-speed module connections in industrial high-speed image sensors, AOI, endoscopes, ultrasound, etc.;

- Optional multi-pair shielded twisted structure, supports custom flexible flat cables (FFC/FPC) and standard cable connections;

- Meets medical-grade material requirements (low toxicity, drug resistance, high-temperature sterilization).

Additional features: Signal anti-misinsertion interface design, electrostatic protection treatment, grounding zones.

Custom High-Speed Differential Harness

- Wire sequence planning, signal distribution layout, and twist optimization based on customer drawings or schematics;

- Supports specified impedance (85Ω / 100Ω), precise wire length matching, and EMC shielding optimization design;

- Provides various connection methods such as module-to-module, board-to-board, and connector-to-flying lead.

Application scenarios: Embedded AI modules, edge computing platforms, high-definition video capture systems, etc.

General Customization Parameters Supported:

| Parameter Category | Available Options / Range Description |

|---|---|

| Number of Signal Pairs | 1 pair, 2 pairs, 4 pairs, 8 pairs (can include power/control wires as needed) |

| Shielding Options | Individual pair foil shielding, overall shielding, dual shielding (braided + foil) |

| Connector Types | I-PEX, JAE, Molex, TE, Rosenberger, DF19, FI-R, AMP, and other specified brands |

| Wire Types | UL 20276, UL 2464, TPE, FEP, PVC insulation; low-smoke, halogen-free materials available |

| Processing Capabilities | Twisting, ultra-short harness assembly (±0.5 mm precision), heat shrink labels, laser marking, wire ID |

| Certifications | RoHS, REACH, UL, ISO 9001; optional third-party impedance test reports |

Applications of LVDS Wire Harnesses

Application 1: Automotive Camera & Vision Systems

In modern smart cars, LVDS harnesses are widely used to connect onboard cameras to central processing units and support high-speed image transmission protocols such as FPD-Link III, GMSL, and GVIF. Linkwings’ LVDS harnesses utilize high-flex, temperature-resistant cables and connectors from brands such as I-PEX and Rosenberger, featuring EMI shielding, anti-misinsertion structures, and stable impedance control to meet the long-term reliability requirements of automotive electronic systems.

We have provided a 360° surround-view camera wiring harness solution for a European original equipment manufacturer (OEM), enabling high-speed synchronous image transmission. The samples have passed ISO 16750 automotive vibration and temperature/humidity testing. Customer feedback indicates that during mass production, assembly efficiency has significantly improved, and the consistency of vehicle image quality outperforms solutions from other suppliers.

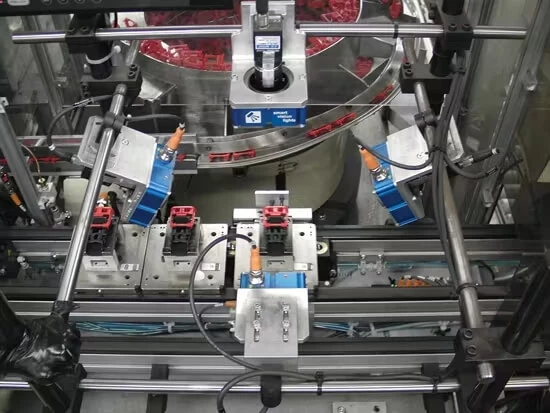

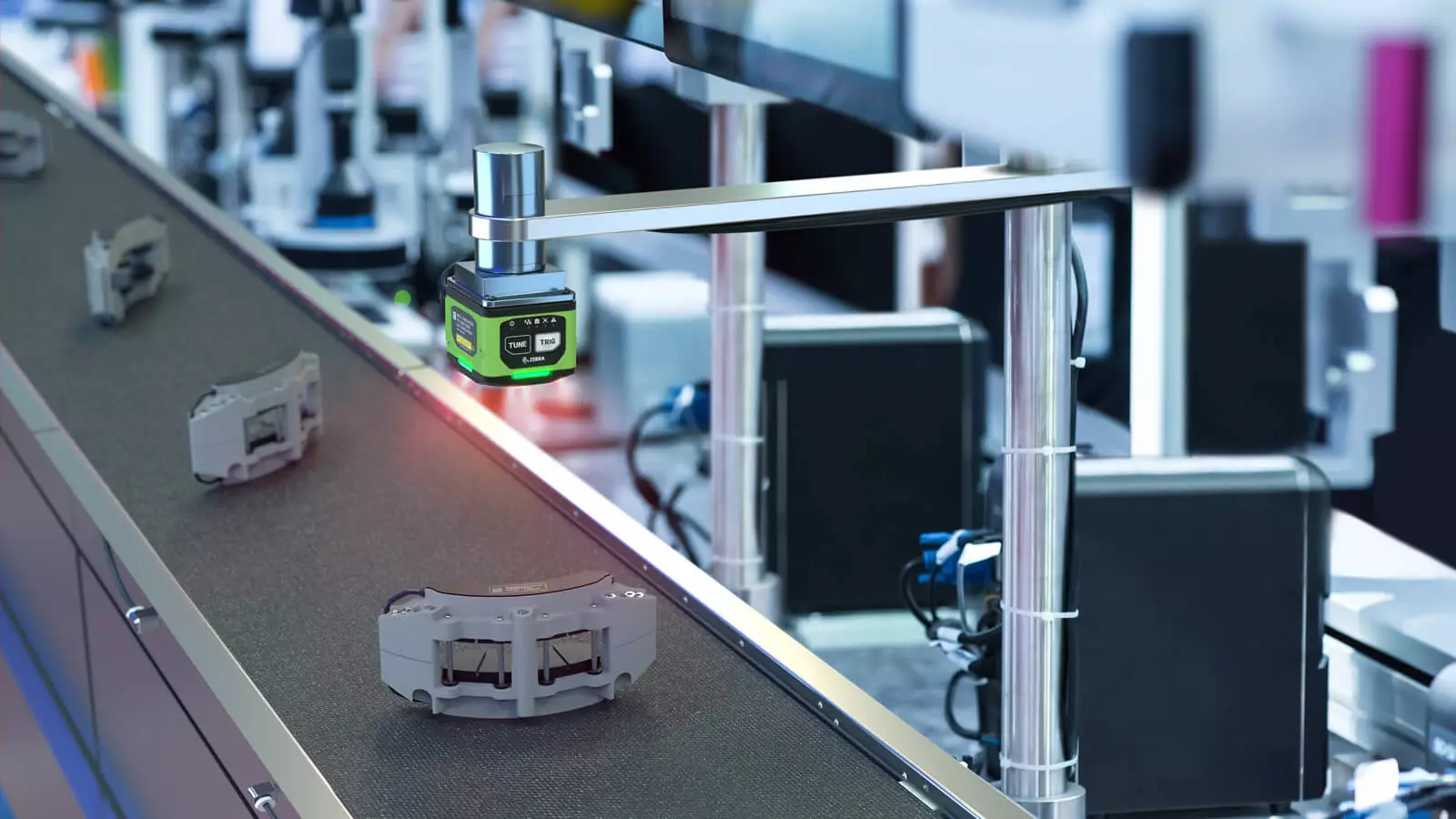

Application 2: Industrial Image Acquisition and Machine Vision Systems

In AOI inspection, robot positioning, and industrial camera image acquisition systems, LVDS cable assemblies are responsible for high-bandwidth, low-latency image data transmission. Linkwings can design shielded differential pairs and customize twist pitches according to the requirements of different industrial control boards or sensor modules, and quickly connect to interfaces such as JAE, Molex, and DF19.

We developed an 8-pair high-speed LVDS cable assembly with an overall shielded structure and connector grounding treatment for a German industrial equipment client, effectively suppressing electromagnetic interference and ensuring stable operation of the equipment under high-frequency vibrations and metal enclosures. The client reported a significant reduction in image frame loss rates and excellent cable assembly consistency during mass production use.

Application 3: Medical Imaging Systems and Portable Diagnostic Devices

Portable ultrasound devices, endoscopes, diagnostic modules, and other medical equipment commonly use LVDS interfaces to achieve high-definition image signal transmission, placing higher demands on signal integrity and cable flexibility. Linkwings provides LVDS cables compliant with medical electrical standards, available in materials such as FEP, silicone, and low-toxicity PVC. We also support small-pitch, high-density connector soldering and module packaging connections.

One of our Canadian clients used our custom-made 4-pair LVDS high-speed cable assemblies in the development of a portable diagnostic device. After undergoing continuous bending tests of 200,000 cycles without any damage, the product successfully passed the IEC 60601 medical safety certification. The client subsequently applied our cable assemblies to multiple new device platforms, establishing us as their core long-term supplier.

Application 4: Smart Display Terminals and Embedded LCD/Display Modules

In industrial touch panels, smart terminal devices, and in-vehicle displays, LVDS cable assemblies are used to connect the driver mainboard to the LCD module, enabling high-resolution image output. Linkwings offers a variety of screen-to-screen and board-to-board LVDS connection solutions, supporting both separated and ribbon cable structures, compatible with multiple interface protocols, and capable of structural customization according to display manufacturer standards.

We supplied a high-consistency 6-pair LVDS panel cable assembly to a Japan-Korea joint-venture display module manufacturer. All cable pairs have impedance matching errors controlled within ±5Ω, and are compatible with FFC, DF14, and FI-R series connectors. This solution has been mass-produced across multiple end-customer platforms, significantly reducing assembly errors and RMA return rates.

FAQs about Wire Harness

1. Does Linkwings support customization of LVDS cable assemblies with different interface types?

Yes. We support a variety of mainstream connectors, including I-PEX, JAE, Molex, TE, Rosenberger, DF19, FI-R, and more. We can customize the cable assembly structure and interface layout based on customer-provided drawings, samples, or interface models.

2. Can you guarantee the impedance consistency of LVDS cable assemblies?

Yes. We have a comprehensive wire pair twist control process and TDR (time domain reflectometry) testing procedure. This ensures that the impedance of differential pairs remains stable within the 85Ω/100Ω specification range, meeting the requirements for high-speed signal transmission and EMI.

3. What is the maximum number of differential signal pairs supported by LVDS cable assemblies?

In the standard configuration, we support 1–8 differential signal pairs (expandable to a maximum of 10 pairs). In addition, power lines, control signal lines, and other types of lines can be mixed, providing a flexible structure suitable for complex applications such as industrial vision, multi-channel image acquisition, and AI edge computing.

4. Can you provide processing services with precise wire length control?

Yes. We have ±0.5mm wire length control capability, which is suitable for systems with strict synchronization and wire pair matching requirements. All wire harnesses are tested for continuity and length verification before leaving the factory to ensure accuracy and consistency.