Home » Marine Battery Wire Custom from Manufacturer

Custom Marine Battery Wire from Wire Harness Manufacturer

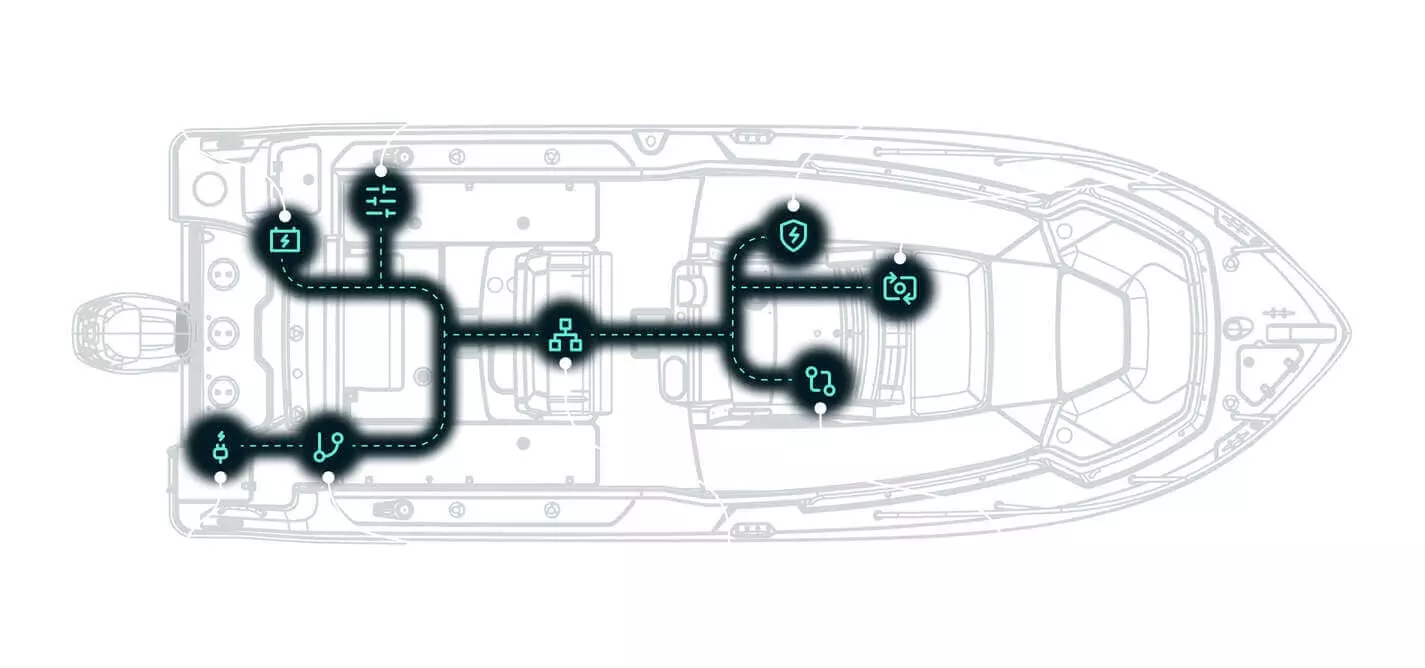

In ships, yachts, and various types of marine equipment, marine battery wire is a core component that ensures the stable operation of power systems and critical electrical equipment. As a professional manufacturer of marine wiring harnesses, Linkwings provides custom marine battery wire solutions that are highly corrosion-resistant, moisture-resistant, and salt spray-resistant.

Custom Marine Battery Wire from Wire Harness Manufacturer

In marine environments, cables must not only carry high currents but also withstand harsh conditions such as salt fog, humidity, UV radiation, and prolonged vibration. As a professional wire harness manufacturer, Linkwings understands that the reliability of marine battery cables is critical to the stable operation of the entire ship’s electrical system. The custom marine battery wires we provide feature high-purity tin-plated copper conductors and heat-resistant, UV-resistant jackets, and are certified to international standards such as ABYC, UL1426, and ISO 10133, ensuring exceptional conductivity and protective performance even under extreme conditions.

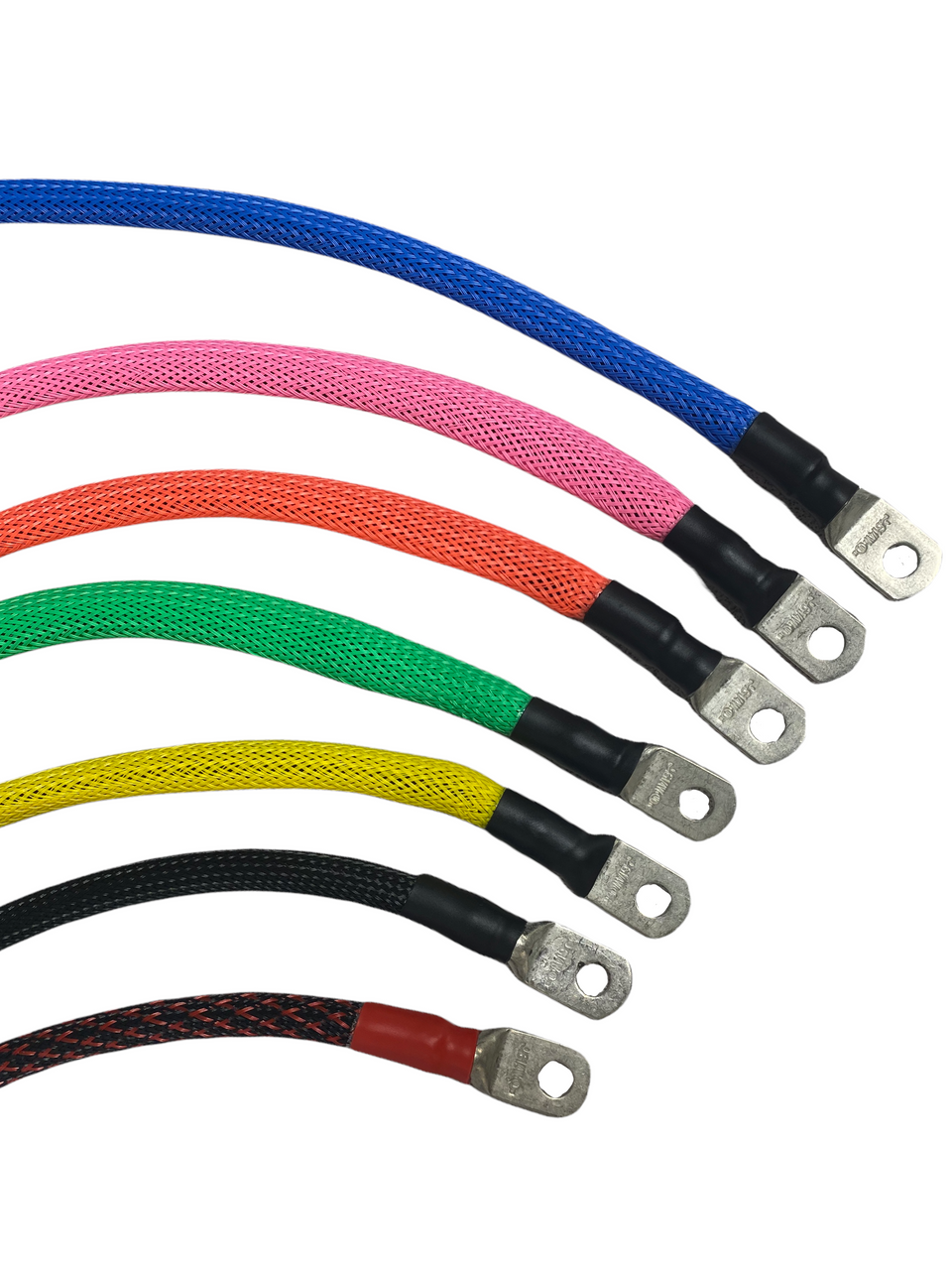

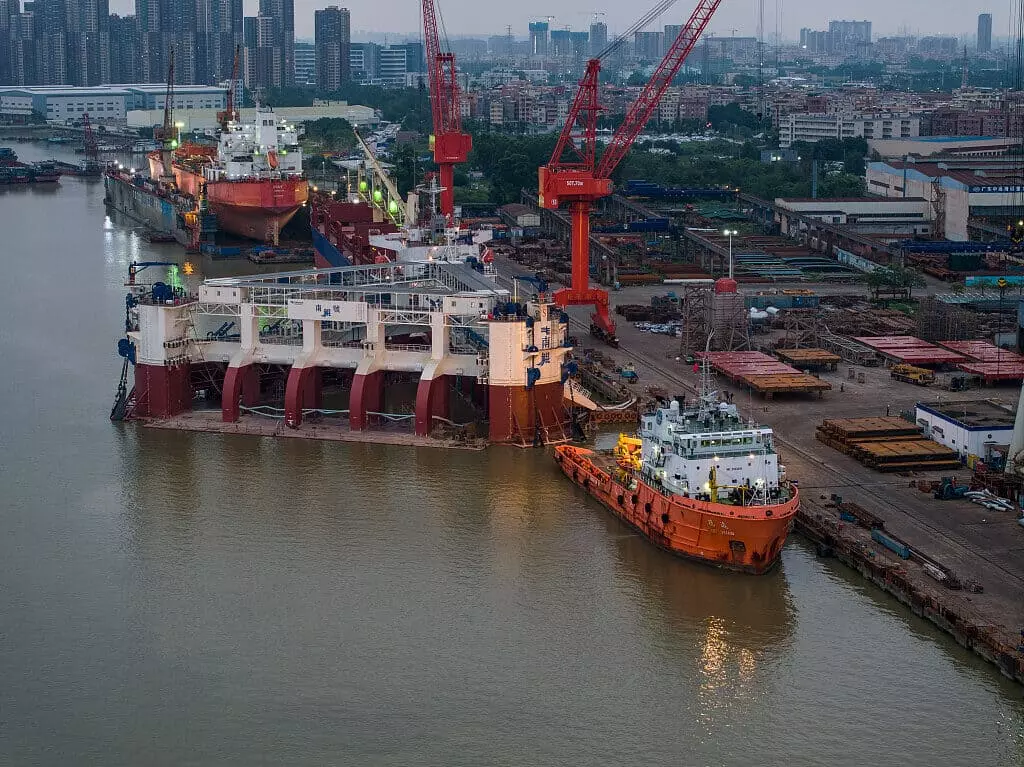

Whether for yachts, commercial vessels, offshore engineering platforms, or specialized rescue vessels, Linkwings can tailor marine battery wire solutions to meet the specific electrical system requirements of our clients. From wire gauge selection, color coding, waterproof construction, to terminal processing, our engineering team is fully involved in the design and testing process to ensure the product not only meets specifications but also optimizes installation and maintenance experiences. Choosing Linkwings means you will have a custom marine battery wire system specifically designed for marine challenges.

Marine Battery Wire Types

To meet the electrical needs of different ships and marine equipment, Linkwings offers marine battery wire in a variety of specifications and structures. Conductors, insulation sheathing, and protection ratings can all be selected based on the actual environment and installation conditions.

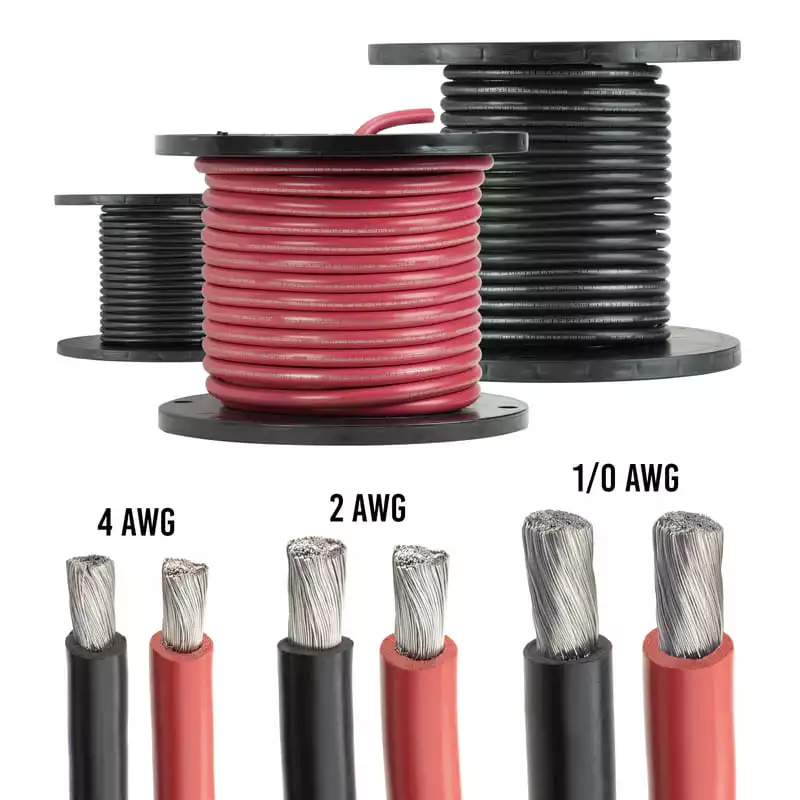

Classification by wire gauge

- 4 AWG marine battery wire: Suitable for powering lighting and navigation systems on small yachts and fishing boats, with a current carrying capacity of less than 150A.

- 2 AWG Marine Battery Cable: Suitable for powering main engine starts and emergency pumps on medium-sized vessels, with a rated current of up to 200A.

- 1/0 AWG Marine Battery Cable: Suitable for main engine starts and connecting multiple battery banks on large yachts and ocean-going fishing vessels, supporting high currents of over 250A.

Features: Large conductor cross-sectional area ensures low-resistance transmission, reducing voltage drop and heat generation.

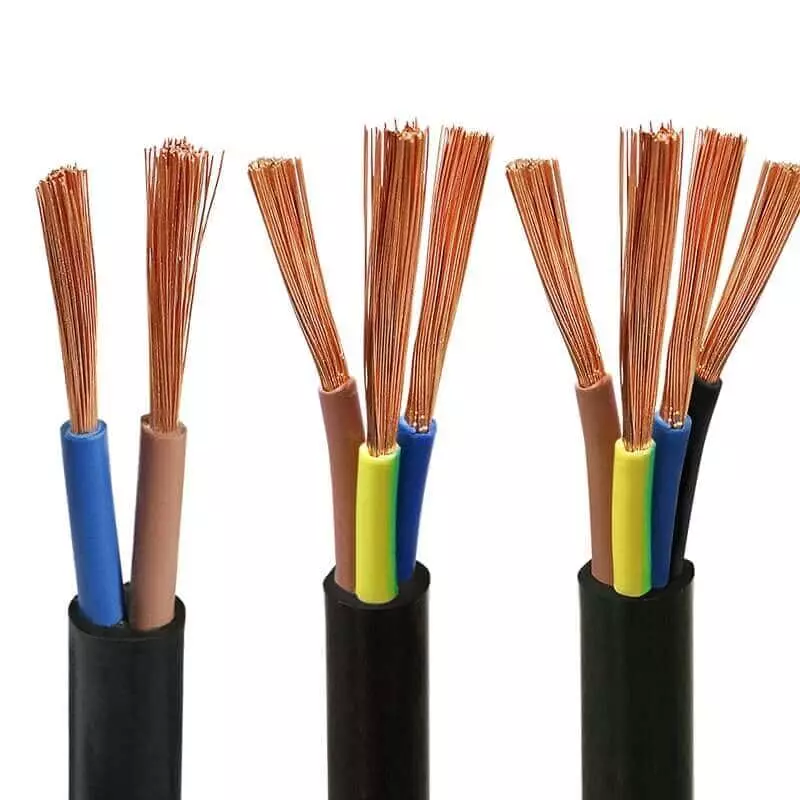

Classification by conductor material

- Tin-plated copper conductor: Strong resistance to salt spray and moisture corrosion, extending service life, making it the preferred choice for marine environments.

- Bare copper conductor: Higher conductivity, suitable for short-term or enclosed environments.

Features: Multi-strand fine stranded structure, enhancing flexibility, convenient for wiring in narrow spaces in ship compartments.

Classification by Insulation and Sheathing Materials

- PVC (Polyvinyl Chloride) Insulation: Cost-effective, wear-resistant, suitable for general marine environments.

- XLPE (Cross-linked Polyethylene) Insulation: Heat-resistant (up to 125°C), resistant to chemical corrosion, suitable for high-temperature environments such as engine rooms.

- TPE/Neoprene Sheathing: UV-resistant, oil-resistant, and saltwater-resistant, suitable for deck and outdoor exposed environments.

Features: All meet marine-grade flame-retardant and low-smoke, halogen-free requirements, enhancing safety.

Classified by protection rating

- IP65 protection: Dustproof and splash-proof, suitable for installation inside ship cabins.

- IP67 Protection: Can withstand short-term immersion in water, suitable for temporary exposure in areas below the deck or outside the cabin.

- IP68 Protection: Can withstand long-term immersion in water, suitable for special applications such as underwater equipment and buoys.

Features: The higher the protection rating, the stricter the requirements for sealing and corrosion resistance, resulting in a longer service life.

| Wire Gauge (AWG) | Conductor Area (mm²) | Rated Current (A) | Outer Diameter (mm) | Conductor Structure (Strands/Diameter) | Insulation Thickness (mm) | Operating Temperature (℃) | Available Colors |

|---|---|---|---|---|---|---|---|

| 4 AWG | 21.15 | 150 | 10.5 | 133 / 0.40 | 1.5 | -40 ~ 105 | Red / Black / Yellow / Blue |

| 2 AWG | 33.62 | 200 | 12.5 | 259 / 0.40 | 1.8 | -40 ~ 105 | Red / Black / Yellow / Blue |

| 1/0 AWG | 53.48 | 300 | 14.5 | 266 / 0.50 | 2.0 | -50 ~ 125 | Red / Black / Yellow / Blue |

| 2/0 AWG | 67.43 | 350 | 16.0 | 322 / 0.50 | 2.0 | -50 ~ 125 | Red / Black / Yellow / Blue |

Application of Marine Battery Wire

Marine battery wire is widely used in ships, yachts, offshore engineering platforms, and other marine electrical systems, where it must meet extremely high standards for corrosion resistance, stability, and safety. As a professional marine battery wire manufacturer, Linkwings provides customized solutions that comply with international marine electrical standards for different application environments.

1. Marine and Yacht Power Systems

Application Requirements: High instantaneous current during engine startup requires low-resistance, high-current transmission capability, along with high-temperature resistance, oil resistance, and vibration resistance.

Linkwings Solution: Utilizes high-purity tin-plated copper conductors and high-temperature-resistant XLPE insulation to ensure low voltage drop and long-term reliability, and is certified to ABYC E-11 and ISO 10133 standards.

2. Marine Navigation and Communication Systems

Requirements: Power supply must be stable to avoid voltage fluctuations affecting critical communication equipment such as radar, GPS, and VHF.

Linkwings Solution: Provides anti-interference shielding structures and multi-color identification cables to reduce electromagnetic interference (EMI) and improve data transmission and power supply stability.

3. Marine Engineering and Platform Equipment

Requirements: Exposed to salt spray, humid heat, and UV radiation year-round, with some cables subject to periodic immersion.

Linkwings Solution: IP68 waterproof rating structure with neoprene rubber sheathing and double-layer sealed terminals to ensure long-term corrosion resistance and high mechanical strength.

4. Multi-battery packs and energy storage systems

Requirements: High flexibility cables are required for easy wiring in narrow compartments, with high current carrying capacity.

Linkwings solution: Ultra-fine stranded tinned copper conductors are used in combination with flexible insulation materials to support small bending radius wiring and reduce installation difficulty.

FAQs about of Marine Battery Wire

Q1: What is the difference between marine battery wire and ordinary battery wire?

A1: Marine battery wire is specifically designed for marine environments and typically uses high-purity tin-plated copper conductors. It offers excellent resistance to salt fog, humidity, heat, and corrosion. The insulation material is often high-temperature resistant and UV-resistant XLPE or neoprene rubber, and complies with marine electrical safety standards such as ABYC, UL1426, and ISO 10133. Ordinary battery wire is primarily used in land-based environments and has relatively lower protective performance.

Q2: Can marine battery wires be used while submerged in water for extended periods?

A2: Yes, but you must select a model that meets the IP68 protection rating and ensure that the terminals and connectors are waterproof. Linkwings’ marine battery wires can operate in saltwater environments for extended periods and have passed salt spray and waterproof testing, making them suitable for use on decks, outside compartments, or underwater equipment.

Q3: Does marine battery wire need to be replaced regularly?

A3: Under normal usage conditions, high-quality marine battery wire can last up to 8-10 years. However, if you notice that the insulation layer has aged, hardened, cracked, or the conductor has corroded, you should replace it immediately. Linkwings cables have undergone weather resistance testing, which significantly extends their service life.