Home » Solar Wire Harness Manufacturer

Custom Solar Wire Harness Manufacturer - Linkwings Professional Custom Solar Wire Harness Solutions

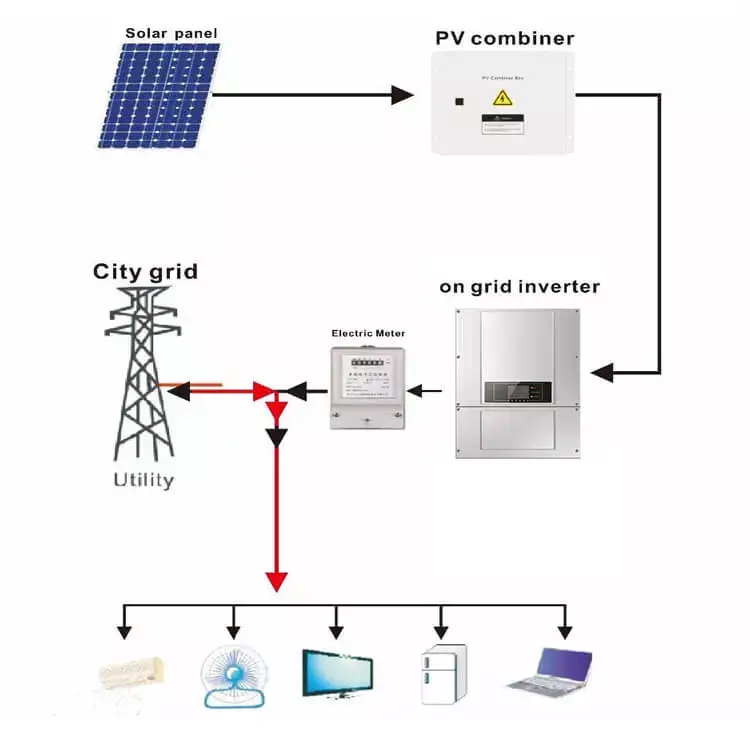

As an experienced solar wire harness manufacturer, Linkwings specializes in providing high-quality, customizable wire harness solutions for solar energy systems. We design and manufacture solar wire harnesses for photovoltaic modules, inverters, convergence boxes, and energy storage systems to meet the stringent requirements of current carrying, weathering, and connector compatibility for a variety of projects. Whether you are an EPC contractor, an equipment manufacturer, or a system integrator in need of customized wire harnesses, Linkwings can provide you with reliable, efficient engineering support and fast delivery capabilities!

Solar Wire Harness Series

As a professional solar wire harness manufacturer, Linkwings offers a wide range of solar wire harness products. The range of wire harnesses covers everything from the connection of the PV modules to the energy storage system. Each product can be customized according to the actual working conditions. This includes wire gauge, color, jacket material, terminal type, and protection rating to ensure a perfect fit for your system.

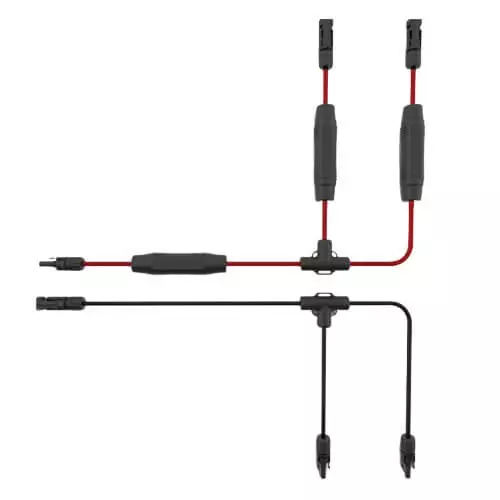

String Harnesses

Suitable for electrical connections between PV modules, typically used to connect multiple modules in series and then parallel to a combiner box.

Features:

- Comes standard with MC4 or Amphenol waterproof connectors.

- UV- and temperature-resistant XLPE or TPE sheathing

- Supports two-conductor or single-conductor configurations

- Customized wire length (accuracy ±5mm) to reduce field wiring time.

- Applicable voltage: Maximum 1500V DC

- Translated with DeepL.com (free version)

Combiner Box Harnesses

Used for wiring sections that converge from multiple component strings to a combiner box.

Features:

- Fuse holders, grounding wires, quick disconnects can be integrated

- Customized end crimping: pre-assembled copper noses, ring terminals

- Multi-core construction for easy integration of control or monitoring signals

- Sheathing supports UV/flame retardant ratings (e.g. UL 94V-0)

Inverter Harnesses

Connects a combiner box or battery bank to an inverter for high current/high voltage transmission, often requiring EMI suppression and industrial grade connection reliability.

Features:

- Large wire diameter support: 4 AWG ~ 12 AWG

- Optional industrial connectors (e.g. Anderson, Staubli, TE, etc.)

- Optional shielding to meet EMI / RFI protection requirements

- Ground wire integration (PE wire) available

Battery/ESS Harnesses

Applied to solar + energy storage integrated system, connecting battery management system (BMS), power conversion system (PCS) and battery module.

Features:

- Supports high current (up to 200A) copper core harnesses

- Supports integrated temperature/voltage monitoring signal lines

- Flexible cabling with multiple terminals and lithium interfaces

- Supports high sealing ratings (IP67/IP68) for battery compartments

Integrated Solar System Harnesses

Complete wiring harness assemblies customized for OEMs and system integrators to reduce field installation complexity and improve system consistency and safety.

Features:

- Customized complete wiring harness kits based on CAD wiring diagrams or 3D models

- Pre-assembled labels, heat shrink tubing, guide clips

- Uniform color coding, predefined interface orientation

- Modular or one-piece wiring options available

Custom Solar Wire harness from Solar Wire Harness Manufacturer

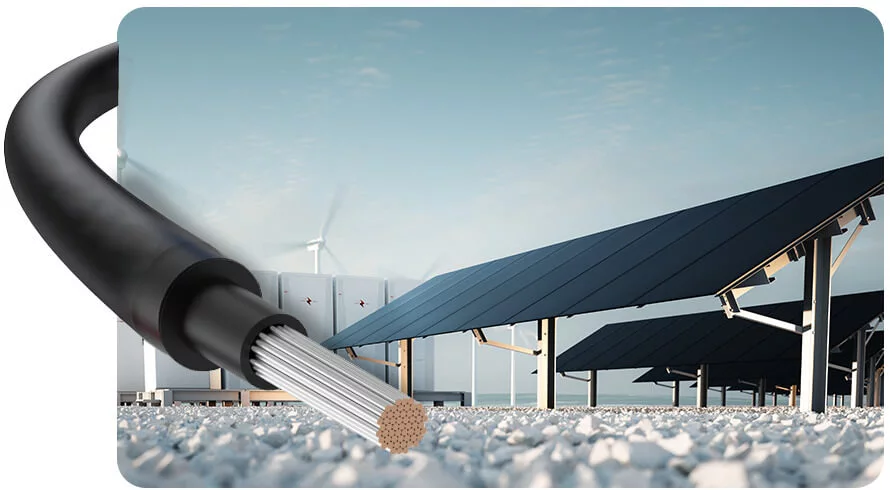

- Wire Gauge (AWG) Range: Support from 4 AWG to 18 AWG, suitable for different current ratings.

- Conductor and insulation material: high conductivity copper core. Sheathing materials: XLPE, PVC, TPE, UV-resistant special materials.

- Connector and terminal types: MC4, Amphenol H4, Anderson, TE, Molex and others. Can be pre-installed ring terminals, fork terminals, copper nose, battery interface connector.

- Protection level and environmental adaptability: Support harnesses up to IP65 / IP67 / IP68. Tensile strength reinforcement, anti-rodent bite braid, UV stabilized layer can be added.

- Color coding and label printing: Cables can be identified by different colors (e.g. red/black/blue/yellow) according to customer requirements. Provide heat-shrinkable labels, spray code printing, numbered ties and other identification methods.

Why Choose Linkwings as Your Solar Wire harness Supplier?

When choosing a solar wire harness manufacturer, we even you are most concerned about product quality, customization ability, delivery efficiency and technical support. As a manufacturer specializing in wire harness solutions for the new energy field, Linkwings has become the preferred partner of many PV system integrators and energy storage equipment manufacturers with its profound technical accumulation and high standard manufacturing system.

Specialized Customization Capabilities

We have an experienced electrical engineering and wiring harness design team. Able to customize to different system architectures, site environments and electrical parameters. We cover all application scenarios from residential rooftop PV to large commercial, energy storage and off-grid systems.

Own Factory

Linkwings has a modern production base. Equipped with fully automated cutting, crimping and testing equipment, Linkwings ensures that every step from prototyping to mass production is strictly controlled. We also strictly implement ISO 9001 quality management system, and 100% of the wiring harnesses have passed the electrical continuity and insulation test before leaving the factory.

International Certifications and Quality Assurance

We provide products that meet the standards of the global market, with UL, TÜV, CE, RoHS, REACH, ISO and other certifications. The traceability of materials is complete, and we can issue certificates of conformity of the original factory and third-party test reports. We also meet the regulatory requirements for export to North America, Europe, Southeast Asia and other mainstream markets.

Rapid Response Engineering Support

Whether you are in the design phase of your project or are in the process of installing on-site, our engineering team can provide timely and professional technical assistance. This includes wiring diagram optimization recommendations, connector selection compatibility reviews and installation and wiring guidance documentation support.

Projects & Applications

Over the past few years, Linkwings, as a professional solar wire harness manufacturer, has provided highly reliable customized wire harness solutions for a number of domestic and overseas photovoltaic and energy storage projects. Below are three typical examples, covering key application scenarios such as residential PV systems, commercial energy storage systems and PV agriculture integration, demonstrating our comprehensive strengths in different environments and technical conditions.

Case 1: Italian residential rooftop PV system (5kW, delivered Q3 2023)

Project Background:

The customer, a green energy company based in southern Italy, plans to deploy distributed 5kW PV systems in several residential areas. The project required wiring harnesses with good UV resistance and fast plugging capabilities.

Linkwings Solution:

- Provide tandem wiring harnesses pre-assembled with MC4 connectors to precisely match the length of the module rows.

- Use of double XLPE insulation for the Mediterranean light environment

- All wiring harnesses are clearly numbered to simplify the installation process for the customer.

- Complete drawings + factory electrical test reports to ensure plug-and-play delivery.

Results:

The customer rated the project highly in their evaluation, reducing installation time by an average of about 20%, and is now expanding to other distributed rooftop projects.

Case 2: Commercial PV + Energy Storage Hybrid System in Malaysia (50kW + 100kWh ESS, Q1 2024)

Background:

This system is located on the roof of a factory in Malaysia, integrating photovoltaic power generation and energy storage, and is required to cope with a high humidity and heat environment and high current loads.

Linkwings Solution:

- Provide a dedicated wiring harness for the energy storage system that integrates the BMS signal and power harnesses.

- Oil- and rodent-resistant TPE jacketing with IP68-rated connectors

- Customized labeling and preformed terminals for each cable to simplify wiring

- Full batch of harnesses tested for high voltage and insulation resistance to heat and humidity

Results:

The system operated without failures for 6 months, and the customer placed an additional order and invited Linkwings to participate in the next phase of the larger-scale PV storage integration project.

Case 3: “Farm-to-Solar” PV Project in Western China (100MW, Q4 2023)

Project Background:

This project is located in the desert area of Western China, adopting the mode of “Agricultural Photovoltaic Complementary”, deploying a large number of ground-mounted module racks, facing challenges of high temperature, high wind, sand and other complex natural environments.

Linkwings solution:

- Provide UV-resistant, abrasion-resistant, high-mechanical-strength tandem and converging harnesses.

- All cables are encapsulated in high-strength nylon bellows with tensile ties

- Customized large diameter (6mm²) harnesses for long cable runs

- All wiring harnesses passed salt spray and thermal shock tests.

Result:

successfully delivered more than 20,000 sets of wiring harnesses, cooperated with the EPC party to efficiently complete the site wiring tasks, and the project was connected to the grid as scheduled.

FAQs about Linkwings Solar Wire Harness

1. How to choose the right size (wire diameter) for solar wiring harness?

A:

Selecting a wire size depends on the amount of current, cable length, and system operating voltage. The Linkwings engineering team calculates the voltage drop and current carrying capacity based on your actual application, and recommends the optimal wire size configuration for the customer (e.g., 412 AWG for the main inverter wires, 1416 AWG for the signal wires). We can also provide sizing recommendation charts and quick calculation tools to help customers make accurate selections to avoid overheating or voltage loss.

2. What certifications do your harnesses meet?

A:

Linkwings offers solar wiring harnesses that support a variety of international certifications, including but not limited to:

- UL 4703 (North American PV cables)

- TÜV Rheinland (European PV module cables)

- RoHS / REACH environmental compliance

- IP67/IP68 protection ratings (depending on connector and package construction)

We can also assist with third party submissions for specific market requirements.

3. Can I do reverse development based on my drawings or original products?

A:

is perfectly fine. All you need to do is provide a physical sample, schematic or wiring diagram, and the Linkwings engineering team can perform reverse modeling, terminal identification and parameter reduction, and provide optimization recommendations. Examples include improved connector compatibility, optimized harness layout, and enhanced weathering performance.

4. How is the solar harness maintained after installation? Does it have a useful life?

A:

Linkwings’ solar wiring harnesses are designed to last up to 25 years under normal use, consistent with the life of most PV modules. It is recommended that harness connection points, terminal crimps, and jacket integrity be regularly inspected to avoid damage from external forces, corrosion, or UV aging. A maintenance advice manual is also available for technicians.