Types of Cable Harness:What are the Differnect Types of Cable Harnesses?

Home » Types of Cable Harness:What are the Differnect Types of Cable Harnesses?

Although the term “cable harness” may appear to be uniform, it is actually an extremely broad umbrella term. There are significant differences between different types of harnesses in terms of design structure, usage environment, voltage level, connection method, dimensional accuracy, etc. If you do not know the type of harness, it is easy to choose the wrong structure just based on appearance or wire gauge.

If you are not clear about the type of wiring harness and choose only based on the appearance or wire specifications, it is easy to choose the wrong structure, misuse scenarios, and even cause electrical failures or system incompatibility problems. Therefore, in the early stage of project development, selection and procurement or product design, understanding the classification of different types of Cable Harness and applicable scenarios is not only a key step in technical decision-making, but also the basis for ensuring system performance and safe operation.

What is a Cable Harness?

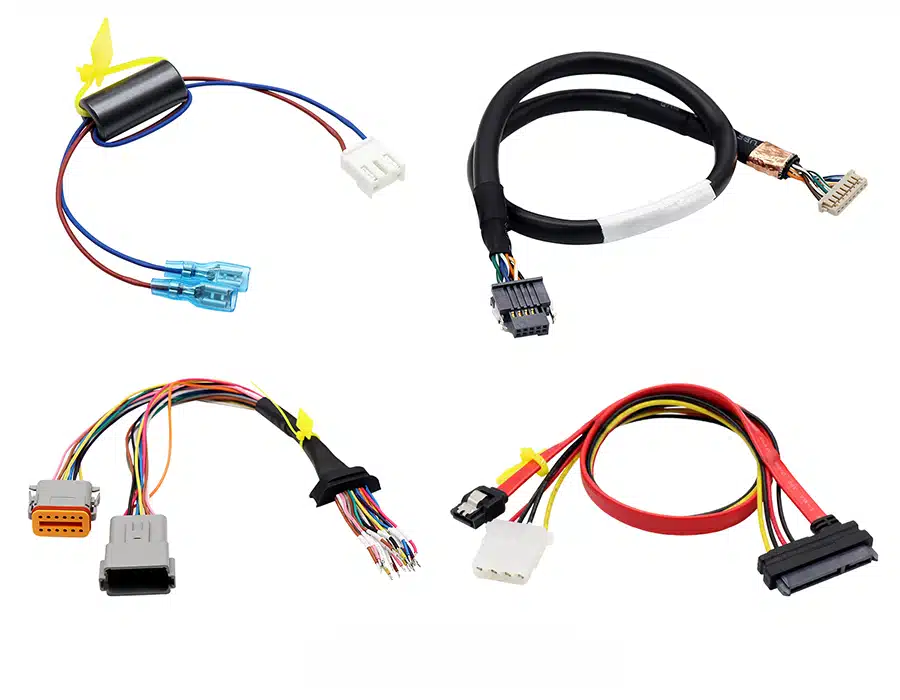

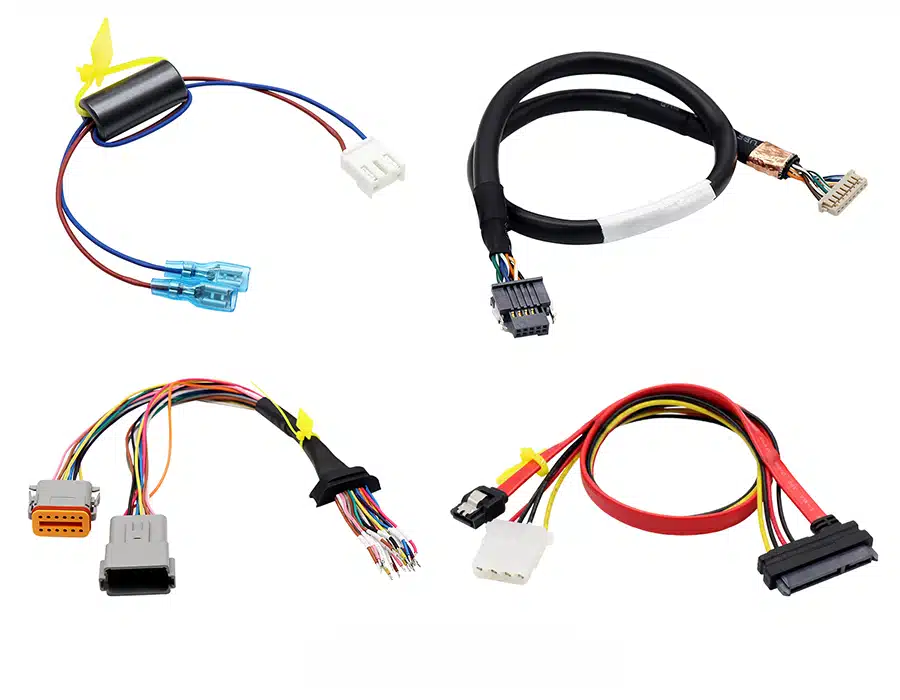

In modern electrical systems, Cable Harness is a component used to organize, bundle and protect wires or cables. This type of harness is often used to integrate multiple wires into a modular wiring structure according to a specific circuit logic. It not only makes the wiring of cables in complex systems clearer and more organized, but also significantly improves connection efficiency, safety and maintainability.

A complete Cable Harness usually includes: wires, cables, connectors, terminals, protective sheathing (such as bellows, heat-shrinkable tubing), ties, fixing clamps, labels and so on. Depending on the application environment, it may have functional characteristics such as tensile strength, waterproofing, shielding, electromagnetic compatibility (EMC), high-temperature resistance, and more.

How Cable Harnesses Are Categorized?

Cable Harness is widely used in all kinds of electrical and electronic systems, different operating environments, system structure and electrical requirements make significant differences in the design of the harness. Therefore, it is important to have a clear understanding of the basis for classifying cable harnesses before actual selection or customization is made to ensure that the product selected meets the combined needs of functionality, performance, and longevity.

Below are some of the most common ways Cable Harnesses are categorized, each with different application criteria and design priorities.

- By Application: Categorized according to the industry served by the harness or the different functions of the terminal equipment.

- By Physical Structure: According to the composition of the wire harness form classification.

- By Electrical Performance: Classified according to the conductivity and signal stability of the harness.

- By Protection Level: Different working environments have special requirements for the protection of wire harnesses.

- By Connector Type

Common Types of Cable harnesses

Cable Harnesses are widely used in industrial, electrical, transportation, new energy and other types of systems. According to the usage and structural characteristics, the following are the most common types of Cable Harness. Each type has its own specific functional scenario and design focus.

Application Scenario: Engine compartment, light system, body control, in-vehicle communication module (such as CAN/LIN bus)

Structure characteristics:

- With a large number of branch structure

- Use of high-temperature resistant insulated wires (e.g. XLPE)

- Covered with bellows, tape or fabric tape

- Waterproof plugs (e.g. AMP Superseal, Deutsch)

Core requirements:

- Vibration, oil, heat and water resistant

- Compliance with IATF 16949, ISO 6722, SAE J1128, etc.

2. Industrial Equipment Harness

Application scenarios: PLC control cabinets, mechanical equipment, robots, CNC machine tools

Structural features:

- Multi-core structure, often with shielding layer

- Equipped with M8, M12, D-sub and other industrial standard connectors.

- Cable with flexible sheath, support multiple bending

Core requirements:

- Anti-EMI interference, compact structure, clear labeling

- Emphasis on installation efficiency and later maintainability

3. Medical Device Harness

Application Scenarios: Medical monitors, ultrasound equipment, electrode interfaces, diagnostic systems

Structural features:

- The use of thin wires, small terminals, highly flexible insulation materials (such as TPU)

- Tight wire layout and clear color differentiation

- Interfaces are mostly customized miniature plugs, such as Hirose, LEMO.

Core requirements:

- High signal integrity, low contact resistance, biocompatibility

- UL, FDA, ISO 13485 compliance is required.

4. Telecom & Data Cable Harness

Application Scenario: Server room, base station, antenna equipment, industrial network

Architectural features:

- Integrated Cat5e / Cat6 network cables, coaxial cables, hybrid fiber optic cables.

- Multi-band shielding, aluminum foil + braid + ground triple shielding structure

- Common interfaces include RJ45, BNC, SMA, fiber optic header, etc.

Core requirements:

- Strong anti-jamming ability, stable data transmission, high voltage performance

- Emphasis on EMI shielding and pair impedance consistency

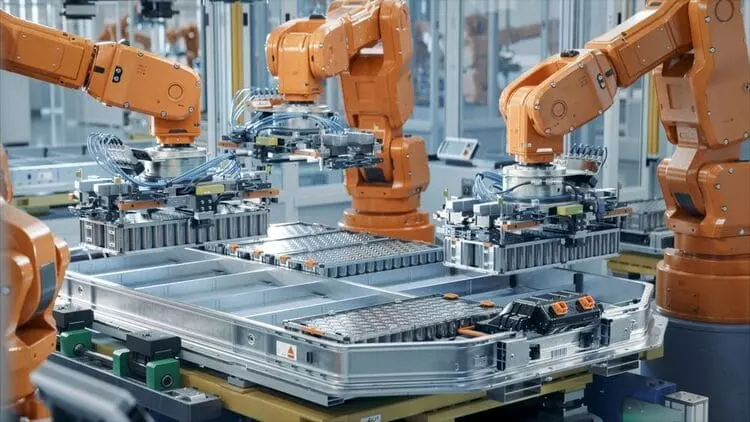

5. High Voltage Cable Harness

Application Scenario: Electric Vehicles, Battery Packs, Photovoltaic Inverters, High Power Power Supply Systems

Structural features:

- Use of orange high-voltage cables (such as EVUS, HVIL charged detection line)

- High-voltage locking connector with explosion-proof design

- Double insulation layer to enhance anti-leakage protection

Core requirements:

- High temperature, pressure, fire and aging resistant

- Comply with ISO 19642, LV215-1, GB/T 34013 and other standards.

Application Scenario: Vehicle environment, outdoor equipment, agricultural machinery, water pumps, camera systems

Structural features:

- Plugs / sockets with rubber seals or potting encapsulation.

- Waterproof heat-shrinkable tubing and corrugated tubing wrapped around the entire wire harness

- Protection level up to IP65/IP67/IP68, etc.

Core requirements:

- Waterproof, dustproof, corrosion-resistant

- Long-term operation in harsh environments such as rain, sand, salt spray, etc.

Application scenarios: special equipment, modified vehicles, small batch customized system

Structural characteristics:

- Design structure and terminal layout according to customer drawings or samples

- Wiring length, color, direction, labeling completely customizable

- Multi-functional composite structure can be integrated with power lines, signal lines, fiber optic cables, liquid cooling tubes, etc.

Core requirements:

- High flexibility, fast response, short lead time

- Meet non-standard interfaces, space constraints, structure-specific requirements

Use Case Comparison Table By Cable Harness Types

| Cable Harness Type | Typical Applications | Key Features Description |

|---|---|---|

| Automotive Harness | Engine bay, dashboard, CAN bus, lighting systems | Multi-branch structure, heat- and oil-resistant, waterproof connectors |

| Industrial Control Harness | Control panels, PLCs, robotic arms, CNC machines | EMI-shielded, compact layout, standard connectors, service-friendly |

| Medical Device Harness | ECG leads, electrode cables, monitors, endoscopy systems | High-flex wire, miniature connectors, signal integrity, biocompatible materials |

| Telecom/Data Harness | Data centers, base stations, servers, telecom devices | Strong shielding, high transmission speed, RJ45/BNC/fiber connectors |

| High Voltage Harness | EVs, battery packs, energy storage, PV inverters | Orange sheath, high-voltage insulation, anti-explosion connectors |

| Waterproof Harness | Outdoor lights, motors, pumps, farming equipment, cameras | IP67/IP68 rated, sealed plugs, designed for harsh environments |

| Custom Cable Harness | Vehicle modifications, lab systems, small-batch solutions | Fully customizable design, quick response, no MOQ |

How to Choose the Right Cable Harness Type?

There are many types of cable harnesses. Different industries, equipment and use of the environment on the structure of the harness, electrical performance and durability put forward different requirements. Whether the selection is reasonable or not, it directly affects the safety, stability and maintenance costs of the whole system. Therefore, when choosing the right type of wire harness, the following key dimensions should be emphasized.

Factor 1 : Define the environment and working conditions

First you need to determine what kind of environment the harness will be working in.

- Will it be indoors or outdoors? Will it be exposed to harsh conditions such as rain, dust, UV rays, etc. for a long time?

- Are there physical effects such as vibration, shock, heat, oil, corrosion, etc.?

- Is there a need for a specific level of protection (e.g. IP67/IP68) or fire retardant standards?

👉 Example:

If your wiring harness is applied in the engine compartment of an automobile. Linkwings recommends that you use an automotive wiring harness with heat-, oil-, shock-, and water-resistant capabilities.

If you are installing in a base station antenna or outdoor surveillance camera system, it is recommended to use a waterproof wiring harness with waterproof connectors and UV protection.

Factor 2: Analyze electrical requirements: voltage, current, signal type

Determine the wire gauge and construction of the harness based on the electrical parameters of the system.

Are they low voltage control wires, high voltage power wires, or data/signal wires?

- Is there a need to transmit high frequency signals or protection against interference?

- Do the conductors need to be shielded? Is double insulation required?

- Does it contain multiple circuits (power + signal + ground, etc.)?

👉 Example:

- For new energy vehicle power cables, select a high-voltage harness that has an orange jacket, explosion-proof connectors and insulation protection.

- For control harnesses for PLCs and sensors, industrial control harnesses with EMI shielding are recommended.

Factor 3: Judge the connector and interface match

Different devices have different connector standards, which should be noted when selecting:

- Are standard terminals (e.g. JST, Molex, AMP) used?

- Do you need to customize the plug/receptacle mold? Is there a directional or locking structure?

- Is there a need to maintain full compatibility with the customer’s existing interfaces?

- Are wear-resistant connectors to be used for interfaces with high insertion and removal frequencies?

Factor 4: Space, mounting pattern and wiring requirements

Confirm that the wiring is complex, with or without branches, multi-story spaces, or curved paths:

- Is flexible wiring, stretch-resistant, easy-to-install construction required?

- Are modular interfaces required for easy replacement and maintenance?

- Are there installation conditions such as wire length limitations, routing paths, bending radii, etc.?

Factor 5: Need for customization

If the existing standard wiring harness cannot meet the project requirements, consider choosing a manufacturer with OEM / ODM capability:

- Do you need non-standard wire length, color, structure?

- Do you need to integrate multiple functional wires?

- Do you need to add brand labels, product codes, heat shrink tubing identification?

Linkwings —— A pecialized wiring harnesses manufacturer

Linkwings specializes in providing high-quality, customizable cable harness solutions for the automotive, industrial, new energy, communications, medical and other industries. We have a complete production process, including wire cutting, crimping, assembly, testing and packaging, and support the whole process from drawing evaluation to volume delivery.

Whether it’s a standard wire harness or a complex customized project, we can respond quickly to customer needs and provide reliable engineering support and manufacturing services. We support small lot ordering, OEM/ODM, export sampling and international certification, and are your reliable wiring harness partner.

📩 Contact Linkwings today for a customized solution and fast quote!

FAQs about Cable Harnesses

Cable Harness and Wire Harness can be used interchangeably in some cases. Strictly speaking, however, there is a difference between cable harness and wire harness: Wire Harness typically refers to a harness of individually insulated wires, which is simpler in construction and suitable for low-voltage, low-complexity application scenarios. Cable Harness emphasizes structural integrity, often using multi-core composite cables with higher levels of shielding, protection and functional integration.

In short: Wire Harness is more commonly used for simple circuit control systems, such as inside home appliances; while Cable Harness is mostly used for industrial, communications or high-end equipment that requires higher data integrity, waterproofing and anti-jamming. The choice should be based on the complexity of the project, the electrical requirements and the environment in which it will be used.

2. How do I determine what type of harness I need for my project?

Judging the type of cable harness should be based on the usage environment, electrical parameters and structural requirements. For example, waterproof harnesses should be considered for outdoor installation; high voltage harnesses are required for battery systems in new energy vehicles; small medical harnesses with high flexibility and precision plugs are preferred for medical equipment; industrial harnesses are more suitable for control cabinet wiring.

If you are not sure of the selection, it is recommended to provide basic information (voltage and current, operating environment, length, connector type, use of equipment), so that the harness engineer or supplier to assist in recommending a matching program. This will effectively reduce the risk of choosing the wrong one and improve service life and reliability.

3. Can Cable Harness be customized? What information do I need to provide?

Can. As a professional wire harness manufacturer, Linkwings supports OEM / ODM customization service. Customers only need to provide: ① wiring diagram or hand-drawn sketch, ② terminal/plug type (if not available, we can suggest substitution), ③ cable specification or electrical requirements, ④ required length and quantity, ⑤ special requirements (e.g. waterproof, flame-retardant, shielding, etc.).

It doesn’t matter if you don’t have standard drawings, the supplier can assist you in organizing the drawings, making the BOM list, and providing samples for confirmation and mass production.

Choosing the right cable harness matters

Cable Harness is a seemingly “low-profile” part of the electrical system. But its selection is reasonable, directly related to the safety, stability and maintainability of the entire system. Through this article you can learn, different types of harnesses in the structure, performance and application have their own focus, selection can not be blind, more can not be applied.

Therefore, in the early stages of product development or equipment integration, it is recommended that the use of the environment, electrical parameters, installation space and other comprehensive factors for judgment. If necessary, we should consult with experienced harness engineers or manufacturers to ensure that the program is both practical and safe.

📌 Linkwings can provide you with customized development and production services for many types of wiring harnesses, please feel free to contact us for samples or quotation suggestions.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In