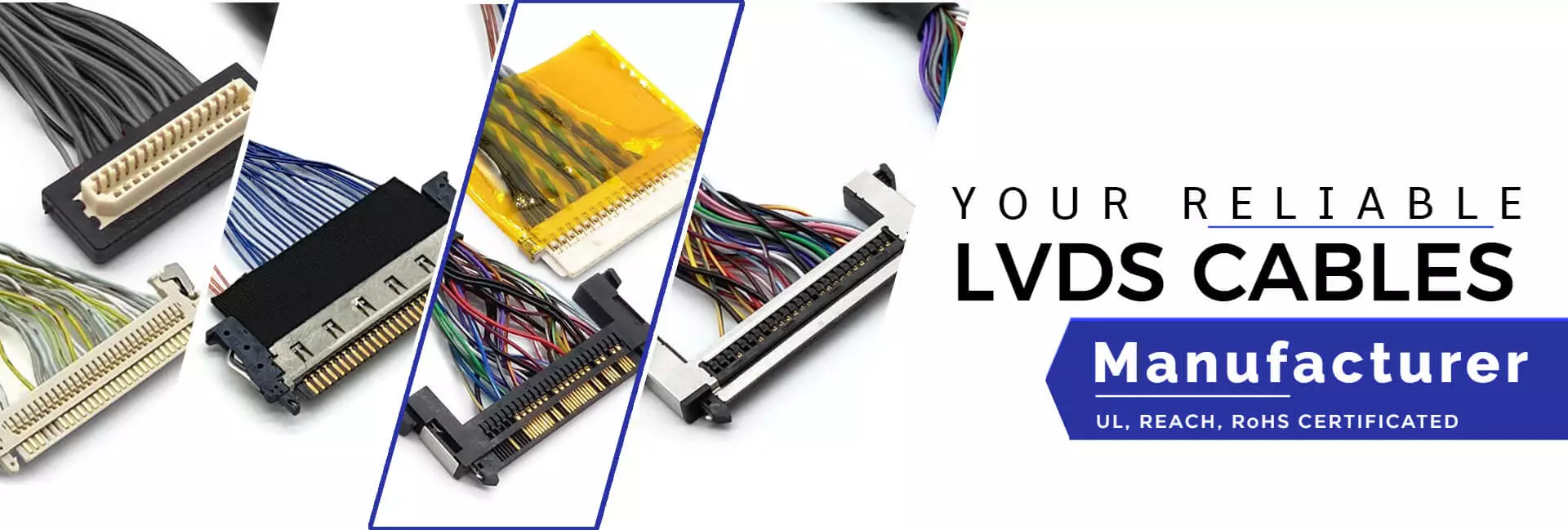

In high-speed signal transmission and display technologies, types of LVDS cables are a frequent topic of interest for engineers and procurement personnel. As carriers of low-voltage differential signals, LVDS (Low Voltage Differential Signaling) cables are widely used in laptops, automotive display systems, industrial controllers, and medical imaging equipment. Different types of LVDS cables exhibit significant variations in structure, shielding methods, channel counts, and connector options. These differences not only impact signal integrity and interference resistance but also directly influence device reliability and overall cost. Understanding and correctly selecting the appropriate LVDS cable type is crucial for ensuring system performance and optimizing design solutions.

LVDS is a high-speed, low-power signal transmission technology. Its core principle involves transmitting voltage signals of equal amplitude but opposite phase through two conductors. The receiver only monitors the voltage difference between them, independent of single-ended levels. This differential transmission method not only significantly reduces external noise interference but also enables data transfer at hundreds of Mbps or even Gbps speeds with low voltage swings (typically around ±350 mV).

Compared to traditional TTL or CMOS single-ended signals, LVDS is better suited for high-resolution displays, automotive systems, and high-speed data links.

Why LVDS Cables Must Employ Twisted Pairs, Shielding, and Impedance Control?

The design of LVDS cables must be centered around signal integrity.

Twisted-pair construction serves as the first line of defense. It ensures that a pair of differential conductors experiences nearly identical electromagnetic interference during transmission, thereby canceling out common-mode noise at the receiver.

The shielding layer acts as the second barrier. Utilizing aluminum foil, braided, or multi-layer shielding combinations effectively reduces external electromagnetic interference and crosstalk between pairs. This is particularly crucial in applications with complex electromagnetic environments, such as automotive and industrial settings.

Impedance control is the third critical factor. LVDS typically requires a differential impedance of 100 Ω. Impedance instability leads to signal reflections and eye diagram collapse, ultimately increasing the bit error rate.

Therefore, LVDS cables must be strictly controlled in terms of geometry, materials, and manufacturing processes to ensure stable high-speed signal transmission.

Types of LVDS Cables

LVDS cables cannot simply be regarded as “the same type of cable.” In reality, based on differences in structure, application, connector form, and channel count, LVDS cables can be categorized into multiple types, each optimized for specific usage scenarios.

1. Classification by Structural Form

- Twisted Pair LVDS Cable: The most common structural form. By tightly twisting a pair of differential conductors, it effectively reduces electromagnetic interference (EMI) while maintaining signal integrity. This cable type is suitable for scenarios with limited routing space but requiring high-speed transmission, such as laptops and monitors.

- Shielded LVDS Cable: To further enhance interference resistance, aluminum foil shielding can be added around each twisted pair, with an outer braided shield. Based on shielding design, it is categorized into single-pair shielding, multi-pair independent shielding, and overall shielding. Shielded LVDS cables are commonly used in complex electromagnetic environments such as automotive, industrial control, and medical equipment.

- Coaxial LVDS Cable: Compared to twisted pairs, coaxial LVDS cables offer superior signal integrity and lower crosstalk. However, they are less flexible and more costly than twisted-pair cables. These cables are typically used in high-speed links or professional equipment demanding exceptional signal quality.

2. Classification by Application Field

- LVDS Cable for Consumer Electronics: Typically used for internal connections within laptop and tablet displays. Features include small wire diameter, high flexibility, and the ability to accommodate confined spaces and hinge bending.

- Automotive LVDS Cables: Used in center console displays, instrument clusters, and in-vehicle cameras. Designs must meet automotive-grade standards, featuring resistance to extreme temperatures, oil resistance, flame retardancy, and high vibration tolerance, along with enhanced shielding to pass EMC testing.

- Industrial LVDS Cables: Widely employed in human-machine interfaces (HMI), industrial displays, and machine vision equipment. Requires abrasion resistance, oil resistance, and long-term operational stability. Outer jackets commonly use PUR or TPE.

- Medical LVDS Cable: Primarily used in high-resolution imaging equipment such as ultrasound, CT, and MRI. Demands low latency, low noise, and exceptional signal integrity. Must withstand chemicals and disinfectants while complying with medical device safety standards.

3. Classification by Connector Type

- I-PEX LVDS Cable: Commonly found in laptops and monitors, characterized by fine pitch, high density, and precise impedance control, making it suitable for high-resolution display applications.

- Hirose LVDS Cable: Employed in high-end electronics and industrial equipment, offering high reliability and compact design, suitable for space-constrained scenarios.

- JST LVDS Cable: Widely used in consumer electronics and certain industrial equipment, characterized by stability, strong versatility, and relatively high cost-effectiveness.

Different connector types directly determine the compatibility between LVDS cables and device interfaces. Therefore, port matching must be ensured during selection.

4. Classification by Channel Count

- Single-Channel LVDS Cable: Suitable for low-resolution or low-bandwidth applications, such as small-sized displays.

- Dual-Channel LVDS Cable: Supports higher resolutions and refresh rates through double the number of differential pairs, commonly used in laptops and automotive displays.

- Multi-Channel Custom LVDS Cable: Designed for ultra-large displays, industrial control systems, and medical imaging equipment. Additional differential pairs can be customized to meet high-resolution and high-speed requirements.

Comparison of Different Types of LVDS Cables

| Type of LVDS Cable | Structure & Shielding | Impedance Control | Flexibility | Typical Applications | Pros | Cons |

|---|---|---|---|---|---|---|

| Twisted Pair LVDS Cable | Differential pairs twisted together; may have overall shielding | Typically 100 Ω differential | High flexibility, small OD | Laptops, monitors, internal LCD links | Good EMI suppression, cost-effective, compact | Limited shielding if unshielded; less robust in noisy environments |

| Shielded LVDS Cable | Each pair with foil shield + overall braided shield | 100 Ω with tighter control | Moderate flexibility, slightly larger OD | Automotive displays, industrial HMI, medical devices | Excellent EMI/EMC performance, reliable in harsh environments | Higher cost, larger diameter, reduced flexibility |

| Coaxial LVDS Cable | Each signal line in coaxial structure with individual shielding | Very stable 100 Ω or customized | Lower flexibility, larger OD | High-speed test systems, aerospace, precision medical imaging | Best signal integrity, minimal crosstalk | Expensive, bulky, less suited for compact devices |

| Single-Channel LVDS Cable | One differential channel (few pairs) | 100 Ω | High flexibility | Small LCD modules, low-resolution displays | Simple, low cost | Limited bandwidth, cannot support high resolutions |

| Dual-Channel LVDS Cable | Two differential channels | 100 Ω | Moderate | Laptops, automotive central display, mid-size screens | Supports higher resolution and refresh rate | More pairs increase size and cost |

| Multi-Channel Custom LVDS Cable | Multiple channels, often shielded | 100 Ω with strict matching | Varies with design | Large industrial displays, automotive clusters, CT/MRI imaging | Tailored to high bandwidth, flexible design options | Expensive, requires precise design and testing |

| I-PEX / Hirose / JST LVDS Cable | Twisted/shielded pairs terminated with specific connectors | 100 Ω | Depends on assembly | Consumer electronics, industrial devices | Reliable connector ecosystem, precise mating | Connector compatibility critical; cost varies |

How to Choose the Right LVDS Cable Type?

In practical projects, selecting the appropriate LVDS cable type requires comprehensive consideration of application requirements, electrical performance, and environmental conditions.

First, determine the number of channels based on resolution and bandwidth needs. For instance, single-channel configurations suit low-resolution displays, while dual-channel or multi-channel setups are ideal for high-definition and large-screen applications.

Second, focus on electrical characteristics to ensure differential impedance remains at 100 Ω and possesses robust shielding performance, thereby guaranteeing signal integrity.

Third, select appropriate insulation and jacket materials based on the application environment: consumer electronics prioritize flexibility and slim profiles, while automotive and industrial applications require resistance to extreme temperatures, oils, and interference.

Finally, connector types must perfectly match device ports, such as I-PEX, Hirose, or JST. Balancing these factors achieves the optimal equilibrium between performance, reliability, and cost.

FAQs

1. Are all LVDS cables interchangeable?

No. LVDS cables are typically customized for specific devices. Differences in pin definitions, connector types, shielding structures, and impedance can cause variations. Using incompatible cables may result in signal loss or even hardware damage.

2. Can LVDS cables support 4K displays?

Standard LVDS cables typically support resolutions up to Full HD or WUXGA. To transmit 4K or higher resolutions, dual-channel or multi-channel LVDS cables are required. However, in many new designs, LVDS is increasingly being replaced by eDP or MIPI DSI for ultra-high-definition displays.

3. What is the difference between shielded and unshielded LVDS cables?

Shielded LVDS cables feature aluminum foil or braided shielding, effectively reducing electromagnetic interference (EMI). They are suitable for applications with high electromagnetic noise, such as automotive and industrial environments. Unshielded cables are lighter, more flexible, and lower in cost, but offer poorer interference resistance.

Conclusion: Understanding the Value of LVDS Cable Types

The selection of different LVDS cable types directly impacts system display quality, signal reliability, and overall cost. Therefore, when making selections, engineers and procurement personnel must conduct a comprehensive assessment based on application scenarios, bandwidth requirements, environmental conditions, and connector compatibility—rather than relying solely on individual parameters or price. An appropriate LVDS cable type strikes a balance between performance and cost while ensuring stable, reliable operation over extended periods.

For users requiring professional guidance or customized solutions, Linkwings leverages extensive industry expertise and a robust quality system to provide the most suitable LVDS cable type selection and tailored solutions.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In