What Are the Different Flexible Flat Cable Types?

Home » What Are the Different Flexible Flat Cable Types?

In modern electronics and industrial applications, Flexible Flat Cable Types have increasingly become a focal point for engineers and designers. Compared to traditional round cables, flexible flat cables offer advantages such as lightweight, thin profile, flexibility, and space-saving properties, enabling high-density wiring within confined device interiors. These cables are widely used in consumer electronics, automotive electronics, medical devices, and industrial automation. Different types exhibit distinct characteristics in performance and application scenarios, making proper understanding and selection crucial.

This article systematically introduces several common Flexible Flat Cable Types, including FFC, FPC, high-speed flexible flat cables, and customized solutions. We will not only analyze their structural and performance differences but also provide selection recommendations based on practical applications, helping R&D and procurement personnel quickly match suitable solutions. As a manufacturer with years of experience in the connector and cable industry, Linkwings is committed to providing customers with professional, reliable, and custom flexible flat cable products and technical support.

A Flexible Flat Cable (FFC) is a cable structure composed of multiple parallel conductors encased within an insulating layer. Due to its neatly arranged, flat ribbon-like conductor configuration, it is thinner and more compact than round cables, enabling high-density wiring within limited spaces. This makes it highly suitable for the miniaturization and integration designs of modern electronic devices.

Core Features:

- Flexibility: The cable can withstand repeated bending without compromising performance, making it suitable for moving parts or confined spaces.

- Space-saving: Its flat design enables tighter routing within PCBs or between modules.

- Repeatable bending: Ideal for applications requiring frequent opening/closing or dynamic connections (e.g., laptop hinges).

- Easy installation: Standardized pitch facilitates quick mating with connectors, enhancing assembly efficiency.

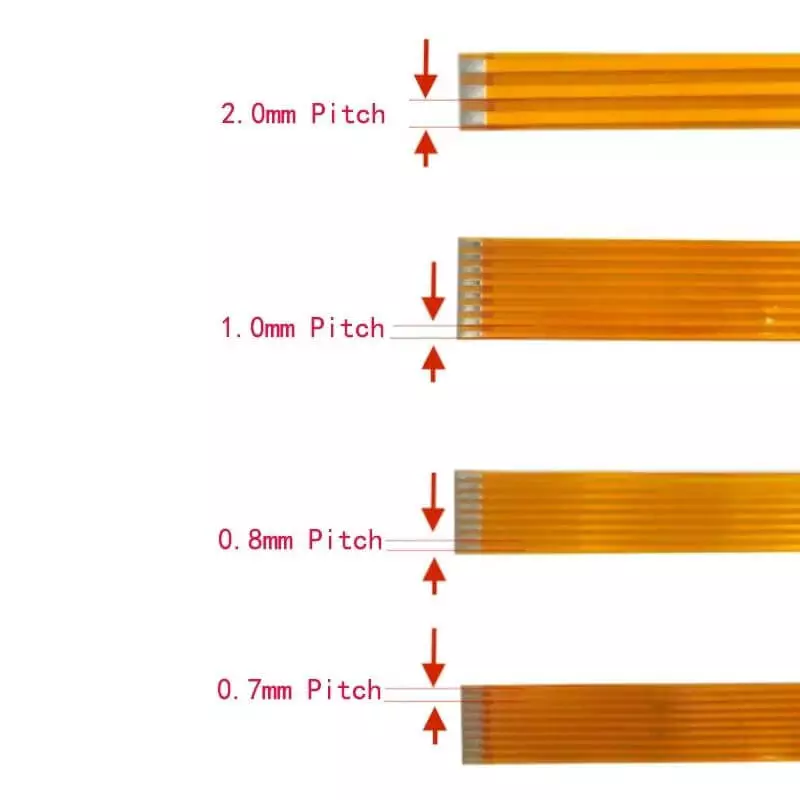

Common Pitch (Spacing) Standards:

Flexible Flat Cable conductor spacing adheres to multiple international standard specifications, with common dimensions including:

- 0.5mm

- 1.0mm

- 1.25mm

- 2.54mm

These standards enable compatibility with a wide range of connectors, covering diverse application needs from miniature consumer electronics to industrial equipment.

Main Types of Flexible Flat Cable

.webp)

1. FFC (Flexible Flat Cable) Standard Flexible Flat Cable

Definition:

FFC is the most common type of flexible flat cable, consisting of multiple copper conductors arranged in parallel and encased within a PET (polyester) or PI (polyimide) cover film. It features a thin, lightweight appearance and simple structure, qualifying as a highly standardized product.

Features:

– Thin profile and lightweight for easy installation;

– Cost-effective, suitable for mass production;

– Common pitches include 0.5mm, 1.0mm, 1.25mm, 2.54mm, etc.

Applications:

Widely used in thin and lightweight consumer electronics such as:

– Connecting laptop displays to motherboards;

– Printer scan heads;

– Internal connections in digital cameras;

– Automotive center console display modules.

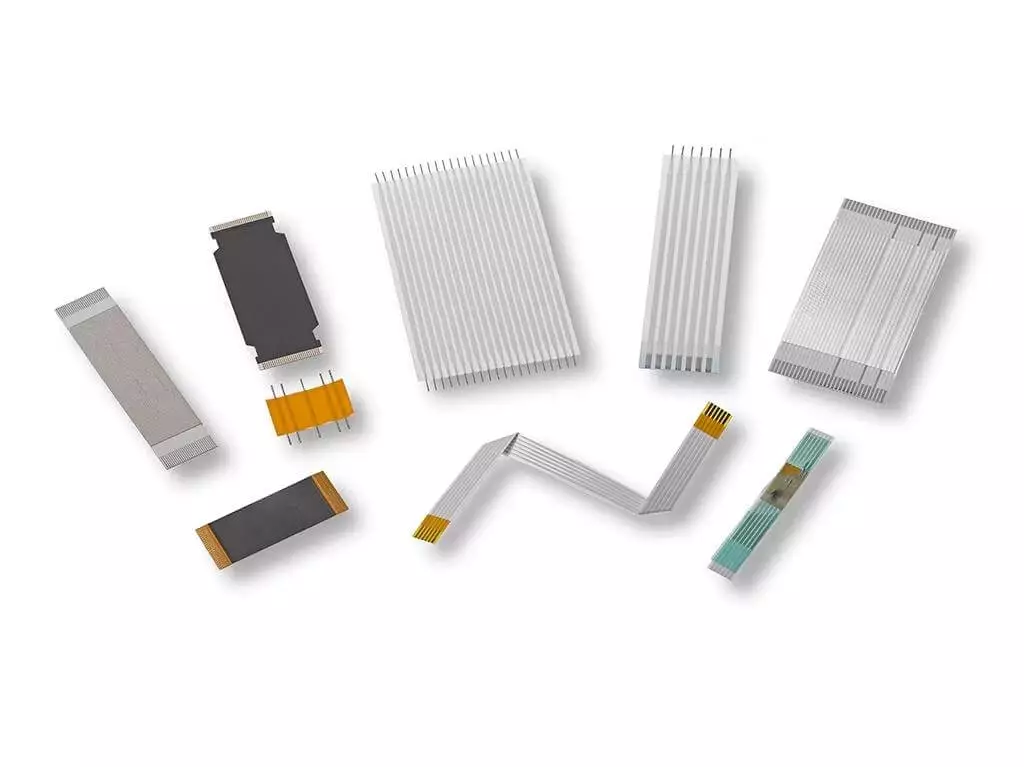

2. FPC (Flexible Printed Circuit)

Definition:

FPC utilizes flexible substrates (such as PI or PET) with copper traces formed on their surface via chemical etching or lamination processes. It functions both as a cable and as a circuit board.

.webp)

Features:

- Enables three-dimensional routing, suitable for complex spatial layouts;

- Can integrate more complex circuit functions beyond simple signal transmission;

- Highly resistant to high temperatures and bending, offering excellent reliability.

Applications:

Widely used in scenarios requiring miniaturization and high reliability, such as connecting smartphone motherboards to displays, medical monitoring devices, automotive radar modules, and wearable devices.

3. High-Speed Flexible Flat Cable (High-Speed FFC/FPC)

Definition:

This cable is specifically designed for high-speed signal transmission. Its structure features impedance optimization and incorporates a shielding layer to minimize electromagnetic interference. It is commonly used for connecting high-speed digital signals.

Features:

- Low crosstalk and low latency ensure high-speed signal integrity;

- Suitable for differential signal transmission (e.g., LVDS, HDMI, USB 3.0);

- Applicable in high-speed data and video transmission environments.

Applications:

Primarily used in high-bandwidth scenarios such as HDMI video interfaces, USB 3.0 data interfaces, 5G communication modules, and data center servers.

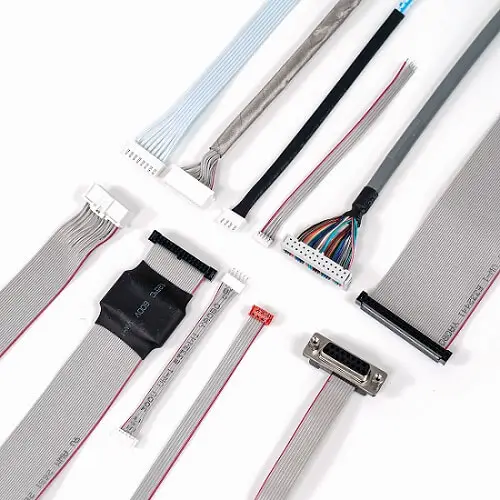

4. Custom Flexible Flat Cable

Definition:

Flexible flat cables tailored to specific project requirements, with adjustable parameters including conductor count, pitch, plating process, and length according to design specifications.

Features:

- Dedicated designs for non-standard interfaces;

- Adaptable to harsh environments (high temperature, bend resistance, vibration resistance, EMI shielding);

- Supports small-batch prototyping and large-scale production.

Applications:

Typically used in high-current wiring for new energy vehicle battery modules, industrial automation control equipment, and compact connections for specialized medical instruments—scenarios demanding exceptional reliability and customization.

Comparison of Different Flexible Flat Cable Types

| Type | Features | Typical Applications | Advantages | Limitations |

|---|---|---|---|---|

| FFC Flexible Flat Cable | Parallel conductors + PET/PI film, thin and cost-effective | Laptop displays, printers, cameras, car infotainment | Lightweight, low cost, widely standardized | Limited current capacity, not for high power |

| FPC Flexible Printed Circuit | Copper traces etched on flexible substrate, supports 3D routing | Smartphones, medical devices, automotive radar, wearables | Can integrate complex circuits, heat-resistant, high reliability | Higher cost, complex manufacturing |

| High-Speed Flexible Flat Cable | Impedance controlled + shielding, supports high-speed signals | HDMI, USB 3.0, 5G modules, data centers | Low crosstalk, low latency, strong signal integrity | Higher cost, strict process requirements |

| Customized Flexible Flat Cable | Customizable conductor count, pitch, plating, length | EV battery packs, industrial automation, special medical instruments | Meets non-standard requirements, adaptable to harsh environments (high temp, vibration) | Cost and lead time depend on customization |

How to Select the Right Flexible Flat Cable?

When faced with multiple types of flexible flat cables, selection should be based on specific project requirements, taking into account the following five key factors:

1. Space Requirements

- For devices emphasizing slim profiles or high-density wiring (e.g., laptops, cameras, automotive infotainment screens), prioritize FFC or FPC solutions.

- For applications requiring high-current transmission (e.g., new energy vehicle battery modules or industrial power supplies), consider customized Flexible Flat Cables or solutions with larger conductor cross-sectional areas.

2. Electrical Performance

- Signal Rate: For high-speed signal transmission (HDMI, USB 3.0, 5G modules), high-speed FFC is recommended due to its controllable impedance and low crosstalk design.

- Current Carrying Capacity: Applications with high current demands (e.g., power systems) should select cables with thicker copper foil or custom cables optimized for power transmission.

3. Environmental Factors

- Temperature: For high-temperature environments, select FPC with PI (polyimide) substrate for superior heat resistance;

- Humidity/Protection: In humid or harsh industrial settings, choose constructions with protective coatings or shielding layers;

- Vibration/Durability: In automotive, industrial automation, and similar applications, prioritize cables with high bend resistance and vibration tolerance.

4. Assembly Process

- For SMT automated placement support, choose surface mount compatible FFC/FPC;

- For high-volume assembly demands, select ribbon cables or customized solutions to enhance assembly efficiency.

5. Cost Factors

- Mass production: Cost-sensitive consumer electronics may opt for standardized FFCs;

- High reliability requirements: For medical devices or automotive electronics, FPCs or high-speed FFC/FPCs are recommended. Though more expensive, they ensure long-term stability.

FAQs

Q1: Can Flexible Flat Cable support high-speed signal transmission?

A1: Yes. High-speed FFC/FPC incorporates impedance control and shielding layers in its design, effectively reducing crosstalk and delay. Therefore, it is commonly used in high-speed applications such as HDMI, USB 3.0, 5G communication modules, and data centers.

Q2: What are the common pitches for Flexible Flat Cables?

A2: Common pitches include 0.5mm, 1.0mm, 1.25mm, and 2.54mm, selected based on interface and application requirements. Smaller pitches suit compact devices, while larger pitches better handle current loads or facilitate manual assembly.

Q3: Does Linkwings offer custom Flexible Flat Cables?

A3: Yes. Linkwings provides standardized FFC/FPC solutions and also supports customization of conductor count, pitch, plating, length, and special materials to meet applications in demanding environments such as high temperatures, vibration resistance, or high current requirements.

Conclusion

As electronic products evolve toward thinner, faster, and more reliable designs, Flexible Flat Cables (FFCs) are seeing increasingly widespread adoption across consumer electronics, automotive electronics, medical devices, and industrial control systems. Whether standard FFCs, FPCs, high-speed FFCs, or customized solutions, each type offers distinct advantages to meet diverse requirements—from low-current signal transmission to high-speed data communication and high-current power delivery.

During the selection process, engineers and procurement personnel should prioritize considerations such as space constraints, electrical performance, environmental conditions, assembly processes, and cost factors to ensure long-term stable operation in real-world applications. As a manufacturer with over 15 years of experience, Linkwings not only offers standardized Flexible Flat Cable products but also provides customized solutions tailored to customer requirements, helping you quickly identify the most suitable product.

👉 If you’re seeking a reliable supplier of Flexible Flat Cable Types, contact Linkwings’ engineering team for expert selection guidance and technical support.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In