What are wire harnesses and what does a wire harness do? Many engineers or business owners, when they first encounter the term Wire Harness, may think:

- “Isn’t it just a couple of wires with a plug?”

- “Can’t we just buy a couple spools of our own wire and splice it in?”

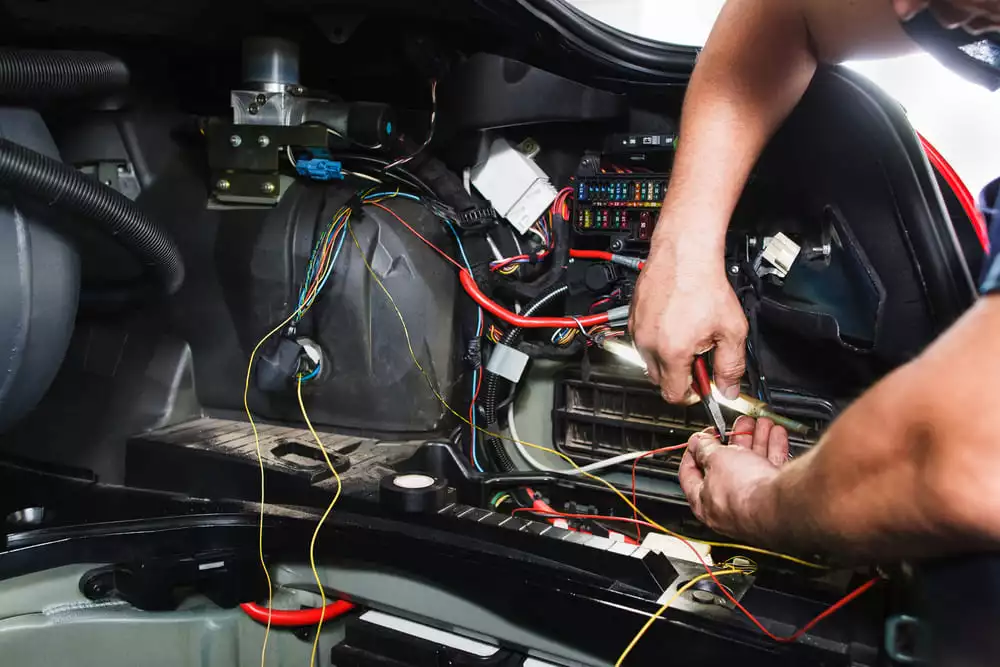

I used to think so – until I got involved in my first full vehicle project. We had to rewire half the car and rewire it because of signal interference, voltage drop and motor failure due to improper wiring of the wiring harness. From that moment on I really understood that the wiring harness is more than just ‘wires’, it is the most central and underestimated part of the entire electrical system.

As a wiring harness manufacturer that has been involved in several new energy vehicles, robotic systems, and control cabinet wiring projects, I’m writing this article to help more people properly understand the role, structure, and principles of wiring harnesses. Whether you’re a business owner, product manager, or R&D engineer, if you’re developing a device that requires electrical control – automotive, industrial equipment, smart terminals, logistics robots – this article will help you sort out a key question:

“What exactly is the role of the wiring harness in the system? How does it work? Why is it so important?”

This is not a boring standard explanation, but based on my actual project experience, summarized “use, understand, avoid the pit” of the wiring harness knowledge. If you want to truly understand the function, selection logic and engineering considerations of wiring harnesses from a system perspective, feel free to read on.

What are wire harnesses?

In my daily project communication, I often hear customers ask me, “What’s the difference between a wiring harness and a regular wire? Is it a core component or not?“

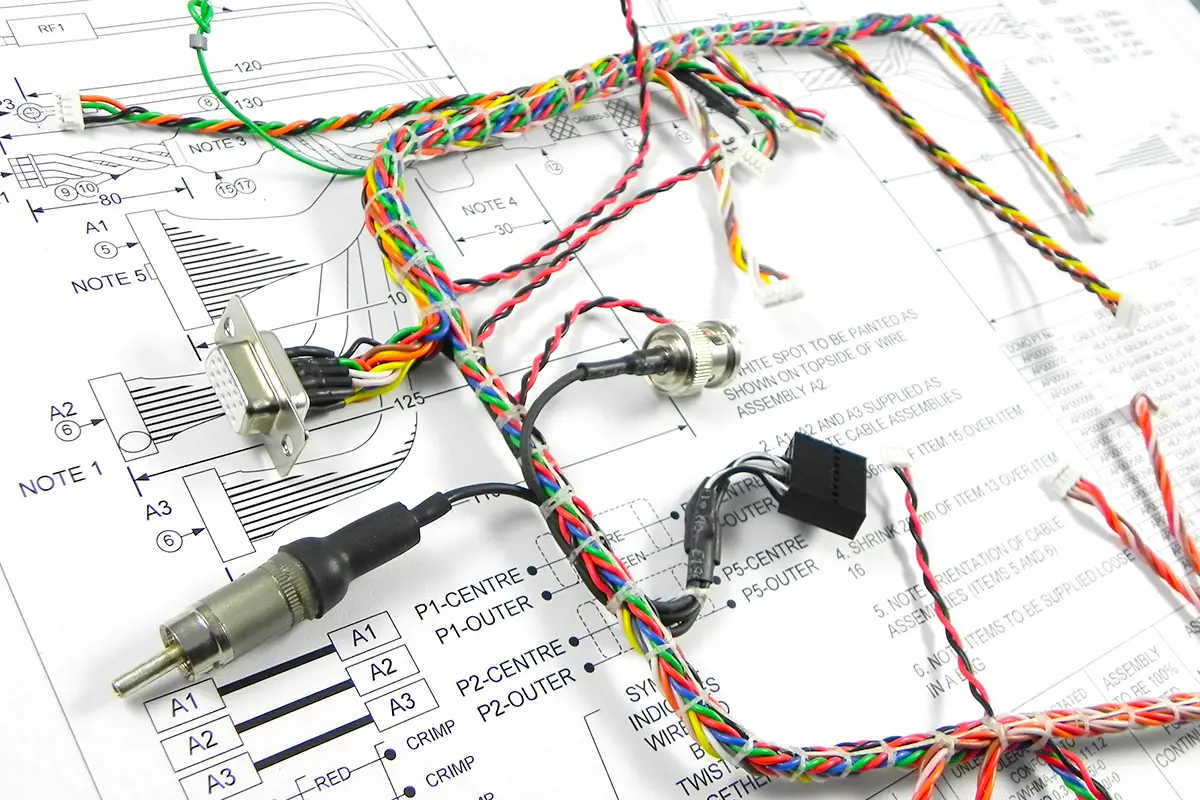

From the engineering point of view, Wire Harness is not simply “multiple wires”, but a kind of wires, cables, connectors, sheaths, fixings and other orderly organization, encapsulation and the formation of installable units of systematic wiring components. Its role goes far beyond the “conductive current” so simple.

Generally speaking, the wiring harness is like the “nervous system of the equipment”. It connects the controller (e.g. ECU, PLC) to the actuators, sensors and other functional modules so that they can communicate correctly and work together.

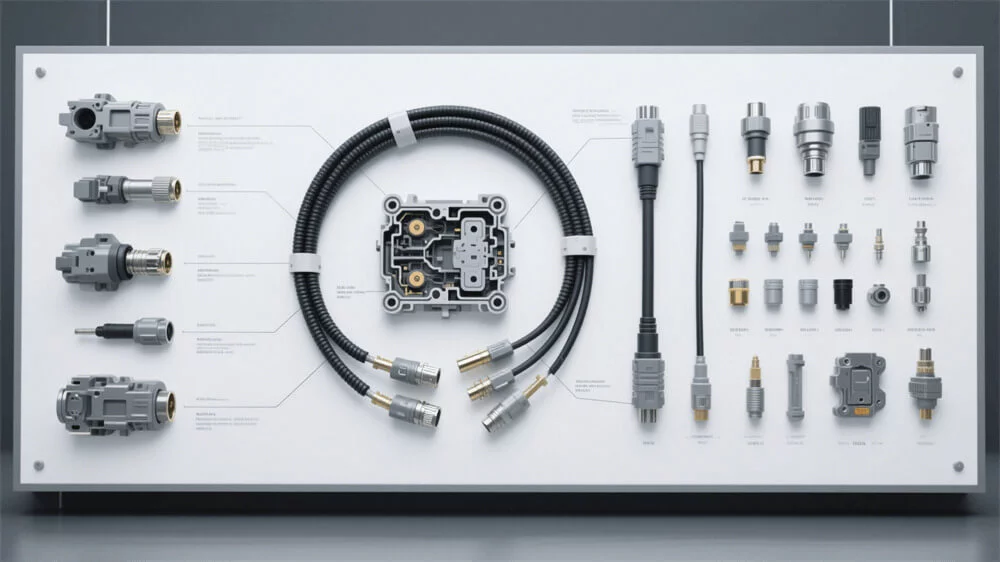

Wiring Harness Components

A complete wiring harness usually consists of the following core components:

- Wires

- Terminals

- Connectors

- Sleeving

- Clips/Ties

- Labels

In some demanding projects, we also use shielding, branch sheathing, and hot melt adhesive sealing heads to enhance the interference and waterproof rating of the wiring harness.

Wiring Harness vs Wire vs Cable, what's the difference?

| Type | Definition & Features | Common Applications |

|---|---|---|

| Wire | Single or few conductors; basic function | Jumpers, internal module wiring |

| Cable | Multi-core conductor with possible shielding | Long-distance transmission, power systems |

| Wire Harness | Structured wiring system with branches and connectors | Automotive systems, control panels, robotics |

For example, a power cable that connects from the battery to the controller is a Cable, but an assembly that connects all the modules of an entire vehicle with multi-branch plugs and routing structures is called a Wire Harness.

Wiring Harness Value

From my project experience: wire harness does not mean wire, it is “structured wiring solution”.

In an intelligent logistics robot project I did, initially the customer used ordinary wires to connect each motor, sensor and control board point to point, which resulted in messy wiring, difficult maintenance, and much interference. After we helped him design a modular wiring harness system:

- Wiring was shortened from several hours to 30 minutes

- The overall weight was reduced by about 20%.

- Signal interference problems were virtually eliminated

- Subsequent maintenance only need to unplug the module, no need to re-cut the wires.

That’s the value of a wiring harness: not only does it keep the equipment running, it also makes it safer, neater and more reliable.

what does a wire harness do?

When we see a set of complex wiring harnesses in automobiles, robots, industrial equipment or control systems, the most common question is: “What does a wire harness do?”

A wiring harness is not just a “collection of wires”, but a highly organized, functionally integrated core component of an electrical system. Its role can be divided into the following levels:

1. Signal transmission: the highway of information flow

Modern equipment has a large number of sensors and control units, and the first role of the wiring harness is to connect the signals between these electronic modules to ensure that the system is functioning properly.

In automobiles, the wiring harness connects the gas pedal, brake sensor, rain sensor, reversing radar, etc., and then through the ECU real-time control to execute the action.

In industrial control, PLC connects each IO module through the wiring harness to realize precise logic judgment and action instruction.

In the intelligent robotic arm project, communication delay is often encountered. Generally, the signal lines are not shielded and cross-layered with the power harness, resulting in frequent interference. After optimizing the wire harness structure, the signal transmission delay was reduced from 180ms to 30ms.

2. Power transmission: the vascular network for system energy

In addition to signaling, another fundamental function of a wiring harness is the transmission of electrical current. From power supplies to controllers, from batteries to drive motors, and from distribution boxes to lighting/fan systems, every current path must be accomplished with a reliable wiring harness.

High current areas will use high voltage harnesses with multiple insulated, protective designs. For low and medium voltage areas, a standard automotive low voltage harness (12V/24V) will suffice.

Of course, the choice of wire diameter is not arbitrary. It is a matter of judgment based on current load, wire length, and allowable voltage drop. This is why the wiring harness is not “the thicker the wire, the better”, but to scientific calculation and layout.

3. Integrated management: “structured solutions” for electrical wiring

A complex device without a harness, the wiring will be as messy as a spider’s web. Not only is it difficult to maintain, but it is also prone to wiring errors, poor contact, and interference problems. The existence of wiring harnesses makes the whole electrical system clear, organized and controllable.

- Supports modularized assembly: a main wiring harness is divided into multiple branch harnesses, which are connected to the doors, lamps, cockpit and other parts of the car, enabling quick docking.

- Reduces failure rate: Structured wiring helps reduce soldering points, improve crimping consistency, and enhance vibration resistance.

- Improve vehicle consistency and assembly efficiency: Instead of connecting wires one by one, OEMs can complete a cockpit assembly in 2~3 minutes with a pre-installed wiring harness kit.

If an automaker needs to design a complete wiring harness from scratch, special attention needs to be paid to the wiring harness layout at the beginning of the design. By adopting a “main + branch” modular wiring harness solution with standard interfaces, assembly efficiency can be increased by about 60% and maintenance time can be reduced by more than half.

4. Environmental protection: dealing with high temperatures, vibration, water vapor and other harsh conditions

Wiring harnesses don’t just operate in “lab conditions”, they must be adapted to a variety of complex operating conditions. For this reason, wiring harness systems are often designed with multiple layers of protection:

- Use of high temperature resistant wires (e.g. TXL, GXL, SXL)

- Shielding to minimize electromagnetic interference (EMI)

- Add bellows, heat shrink tubing, tape wrapping, etc., to prevent the harness from abrasion and short-circuiting.

- Waterproof, dustproof, and anti-loosening structure for connectors (especially in automobile chassis, engine compartment, and other areas)

5. Improvement of installation efficiency and maintenance convenience

Wire Harness is a “factory pre-assembled” modular wiring solution. This solution not only saves assembly time, but also greatly improves maintainability at a later stage.

In a complete vehicle assembly, engineers simply “embed” the wiring harness in its entirety and connect it with quick plugs to complete the wiring. In the event of a malfunction, the wires can be quickly traced according to the label or number. There is no need to cut wires or re-solder.

How Does a Wire Harness Work?

Many non-professionals think of a wiring harness as “a few wires wrapped together”, but from an engineering point of view, this understanding is too superficial. Wiring harness is not just a connecting wire for “energizing”, but a “structured signal and energy transmission system” with clear logic, physical protection and electrical functions.

In my wiring harness projects over the past ten years, whether it is for new energy vehicles design BMS high-voltage wiring harness, or for industrial control cabinets to develop low-voltage modular wiring harness, a clear understanding has always been throughout:

Wiring harness is the electrical system operation of the “skeleton + blood vessels + nerve”, without it, the system operation will be chaotic or even paralyzed.

Essential Functions of Wiring Harness

1. Precise connection

- Each wire has a defined function. For example: 12V power supply line, CAN bus, brake signal line, sensor feedback line, etc. Each wire must be connected to the specified interface (Pin-to-Pin).

- Each wire must be connected to the specified connector (Pin-to-Pin). Incorrect wiring can lead to equipment failure or short circuits.

- Detailed wiring diagrams and Pin Assignment tables are developed during the wiring harness design phase. Ensure that all connection logic is implemented correctly

2. Stabilized transmission

- Power lines transmit current, supply loads need to calculate the voltage drop, resistance to heat, redundancy safety factor.

- Signal lines transmit data, which is especially critical for anti-interference, grounding, and cable shielding.

- High-speed data lines (e.g., CAN/LIN, Ethernet) require consideration of pair impedance matching, strand symmetry, and Signal Integrity.

Wire Harness “Workflow”

A set of wiring harness, not work independently, but as part of the system, between different subsystems to complete the information and energy “flow of collaboration.

Example: The wiring harness of an automobile wiper system works as follows

- The driver presses the wiper switch

- The driver presses the wiper switch → The signals are transmitted to the body control unit (BCM) via the wiring harness.

- The control unit instructs the wiper motor to operate via another set of wiring harnesses.

- At the same time, a feedback signal is transmitted to the instrument, which displays the wiper status.

- If there is an intelligent sensor, the sensor data is transmitted to the BCM through the wiring harness to make a speed control judgment.

This process is assumed by the wiring harness:

- Input signal acquisition (switch control)

- Control signal transmission (control module)

- Power output channel (motor drive)

- Status feedback channel (information return)

- EMI suppression (avoiding interference with rain radar, lights)

Wire Harness Application Examples

Many people mention “wiring harness”, the first reaction is the autotmotive wire harness for automotivew industry. But in fact, all systems that require “power+signal” transmission are almost inseparable from wiring harnesses.

And wiring harness in different industries in the use of the way, design standards and technical challenges, the difference is also very big.

Application 1: Automotive industry

Application Location:

- Main Harness: connecting ECU, fuse box, instrumentation, CAN bus, etc.

- Engine Wire Harness: connects to engine sensors, ignition coils, throttle valve

- Door Wire Harness: connects to electric windows, center lock, speakers, door lights, etc.

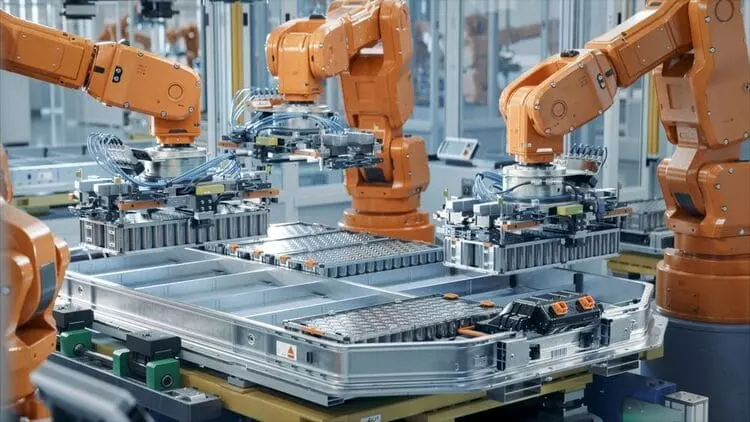

- Battery High Voltage Harness (HV Harness): Used in pure electric vehicles, connecting BMS, electric drive, electronic control.

Technical points:

- High temperature, oil, vibration conditions → materials need to be heat-resistant, corrosion-resistant, vibration-resistant

- Multi-signal interference → need to use shielded wire/twisted pair design to ensure stable communication

- Complex body structure → need three-dimensional wiring diagram support, compact space layout

As an automotive wiring harness manufacturer, we have rich experience in automotive wiring harness design. When designing wiring harnesses for new energy models, we optimized from a distributed control architecture (a dozen sub-harnesses) to a modular structure (main harness + five branches). This design not only reduces the installation labor time by 30%, but also reduces the customer complaint rate by more than 70%.

Application 1: Intelligent robots and automation equipment

Application position:

- Servo Motor Connection Harness: power cable + encoder feedback cable

- Drag chain harness : for robotic arms or moving parts

- Connecting wires between control units and sensors: photoelectric sensors, LIDAR, torque sensors, etc.

Technical Points:

- Bending / drag chain life requirements of high → the need to use highly flexible wire, wear-resistant jacket

- Sensitive to EMI interference → separate wiring for control lines and power lines

- High demand for rapid insertion and removal → the use of industrial-grade quick plug (such as M8/M12)

There was once a warehouse robot project, the customer used ordinary PVC cable to replace the special drag chain cable in the initial stage, and the result was that the cable broke in less than a month. After we replaced it with Linkwings’ recommended ultra-soft PU-coated harness, it successfully passed 300,000 U-bend tests and the product has been running stably for more than 18 months.

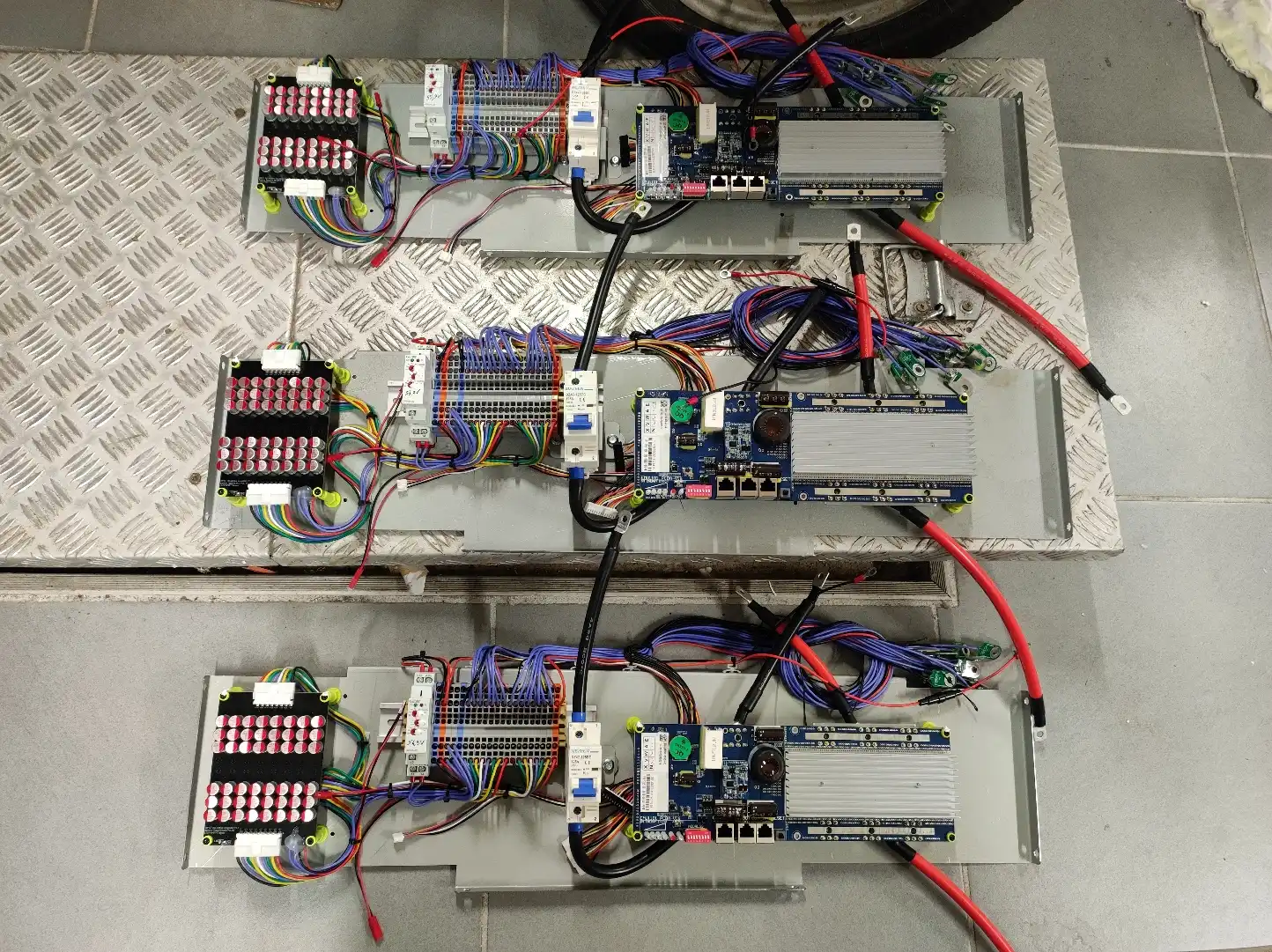

Application 3: Industrial control cabinets and automated production line equipment

Application Location:

- PLC control wiring harness: from the main control module to connect the various IO modules, relays, terminal blocks

- Power supply wiring harness: power supply output in the distribution cabinet and protection system connection

- Signal feedback line: Collecting data from temperature, flow, displacement, stress and other sensors.

Technical points:

- Clear alignment → need to use marking, labeling management, different color distinction

- Various communication requirements → including RS485, Modbus, CAN, Ethernet, etc., wiring needs to be partitioned

- High security level → power lines need to be selected according to the national standard wire diameter, short circuit prevention, high fire requirements

In the development of a complete set of control cabinet wiring harness system, you need to reorganize the original messy wiring into a structured wiring harness + fast plugging program. In this way, the assembly efficiency can be increased by about 50%, and the time for repairing/replacing modules is reduced from 3 hours to less than 20 minutes.

Why is wire harness design important?

Many projects in the early stages of development, it is easy to ignore the wiring harness design. Some engineers even take it as “the final stage of random drawing” of the auxiliary work.

But as a long-term engaged in vehicle electrical architecture, automation equipment wiring engineers, I must emphasize:

Wiring harness design is a project can be stable, safe and efficient operation of one of the key factors.

It is not only the physical connection, but also the blood vessels, nerves and skeleton of the system operation. If the wiring harness design problems, light equipment signal misbehavior, heavy burn components, and even cause a fire. Here are five core reasons why wire harness design is very important:

- The wiring harness transmits current and signals and carries the operational risk of the entire system.

- Electromagnetic compatibility (EMC) design is critical to system stability

- Structural rationality determines assembly efficiency and maintainability

- 90% of the wiring harness cost waste, originating from the design stage of the duplication of routing, selection of unreasonable, low degree of standardization.

- Harness design determines whether the project is scalable/upgradable or not

FAQs

1. What is the difference between a wire harness and wire or cable?

A wire harness is an organized group of wires, usually containing connectors, jackets, labels, etc., used for systematic wiring.

Wire is a single conductor, cable is a collection of multiple conductors, and a harness is a “finished wiring system” with a structural and functional layout.

2. Can a wiring harness carry both power and signals?

Yes, many harnesses contain both power and signal wires. However, it is important to keep power and signal separate when wiring to prevent interference, and to use a shield or separate jacket if necessary.

3. Why are wiring harnesses prone to problems?

Common causes include: wrong wire gauge selection, poor contact, wiring close to sources of interference, poor fixing, and frayed or crushed wire harnesses. Professional design and installation can greatly reduce these risks.

Conclusion

Through this article, I believe you have a clear understanding of “What does a wire harness do”. A wire harness is a systematic and structured electrical transmission solution. It bears the core responsibility of signal transmission, power supply, module connection and system synergy. In modern automobiles, industrial equipment, robots, intelligent hardware and other fields, wiring harness is like a neural network and vascular system – seemingly hidden, but actually critical.

An excellent wiring harness design can make the whole system run more safely, efficiently and controllably. And a bad wiring harness can put the whole project into repeated debugging or even safety risks.

Whether you are an engineer, a business owner, or the head of product development, as long as your project involves electrical connections, wiring harness design should be included in the overall planning as early as possible.

If you are looking for a professional, flexible wiring harness manufacturer with technical support in place, welcome to learn about us – Linkwings.

We are dedicated to providing customized, highly reliable, and small-volume prototyping-supported custom wiring harness solutions for all types of projects, and help you quickly land every electrical system from 0 to 1.

Why Choose Linkwings as your wire harness supplier?

As a professional wiring harness manufacturer from China, Linkwings focuses on providing customized, highly reliable and flexible prototyping wiring harness solutions for automotive, electric vehicle, industrial equipment, robotics and other fields.

Whether you are a startup project, OEM factory, or developing a smart device, we can provide you with:

- Fast response technical support

- Small quantity ordering and flexible sampling

- Strict quality control system (in accordance with IATF 16949)

- Chinese and English communication without barriers, support for exporting worldwide

📩 Have project ideas or sampling needs? Welcome to contact us, let the professional wiring harness team help you land efficiently.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In