What is automotive wiring harness? I believe this is a question that every person or engineer who needs to work with automotive wiring harnesses needs to know.

This blog introduces you to the automotive wiring harness by focusing on “what is automotive wiring harness”. It includes the definition of automotive wiring harness, its components, types, design standards and maintenance issues.

what is automotive wiring harness?

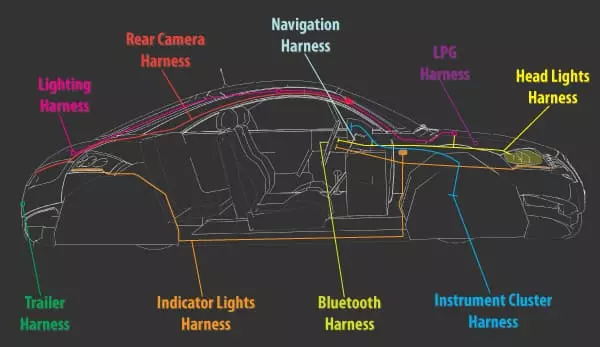

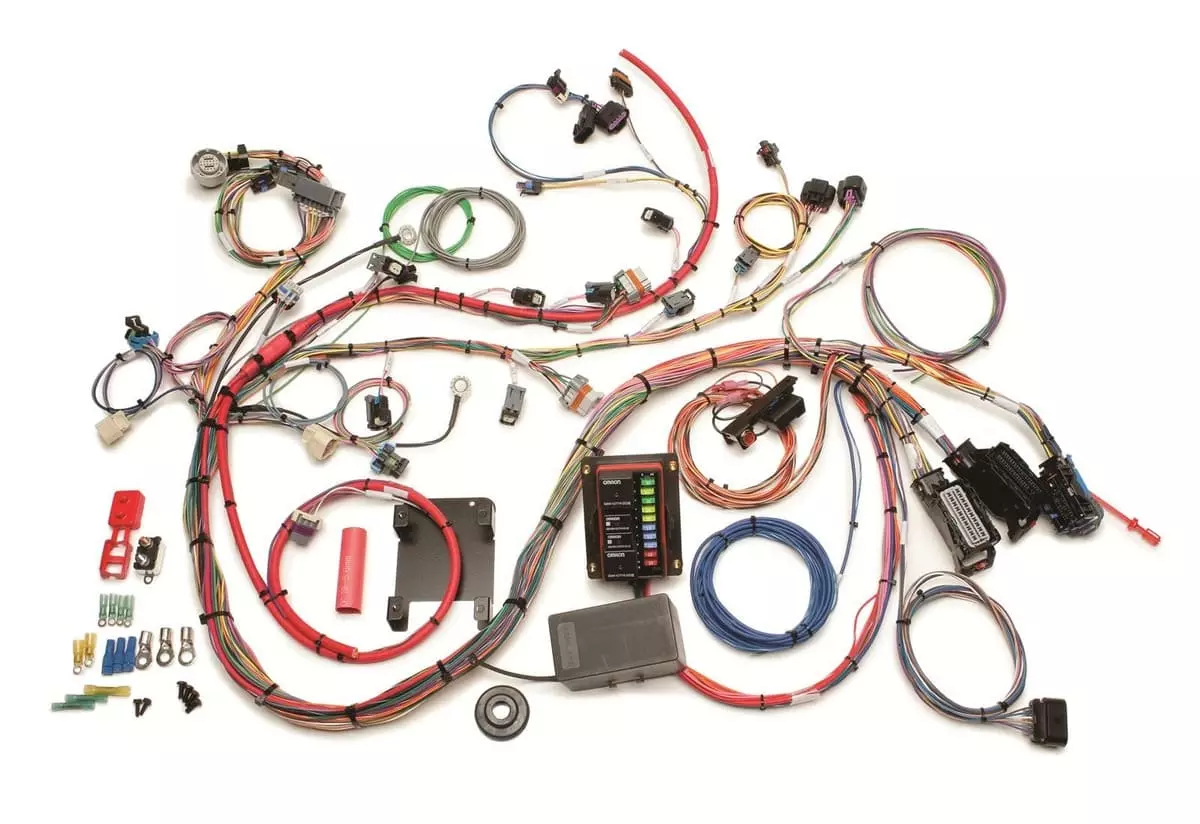

Automotive Wiring Harness is one of the types of wire harness. This type of wire harness is mainly used in automobiles.Automotive wiring harness is an electrical connection system that combines multiple wires, connectors, terminals, sheaths, etc. inside the vehicle in an orderly manner.

It is responsible for the transmission of power and signals between various electronic control units (such as engine, instrumentation, lighting, air conditioning, audio, sensors, etc.) in the vehicle. Therefore, it is often regarded as the “neural network” and “information highway” in the vehicle electrical architecture.

A complete set of automotive wiring harnesses usually includes subsystems such as trunking harnesses, door control harnesses, power cables, sensor wires, CAN bus harnesses, etc., which are modularized according to the space and function distribution of the vehicle. Through standardized ports and plug-in structures, the wiring harness not only greatly improves assembly efficiency and safety, but also provides a stable connection basis for intelligent control, energy-saving operation and post-maintenance of the entire vehicle.

what is the function of a car wiring harness?

The core role of automotive wiring harness is to realize the power supply and signal transmission between various electronic systems in the whole vehicle. It is like the vehicle’s “nervous system”, connecting and coordinating the operation of the engine, lights, instruments, air conditioning, audio, sensors, charging modules and other electrical components.

In the whole vehicle system, the key role of the wiring harness is mainly reflected in the following aspects:

- Power Distribution: Transmits electrical energy from the battery or generator to each electrical device to ensure the normal operation of the system.

- Signal transmission: Transmits data collected by sensors to the control unit (e.g. ECU), and then sends commands to the actuator to realize intelligent control.

- System interconnection: Integrate multiple sub-systems such as engine control system, body control system, infotainment system, etc. to realize unified and cooperative work.

- Safety and Reliability Guarantee: Through standardized wiring, anti-interference structure and anti-dumbing design, it reduces the points of failure and improves the stability and safety of the whole vehicle.

In short, without the wiring harness, the electrical function of the whole car will not work, it is a modern automobile from the “mechanical drive” to the “electronic control” of the basic carrier!

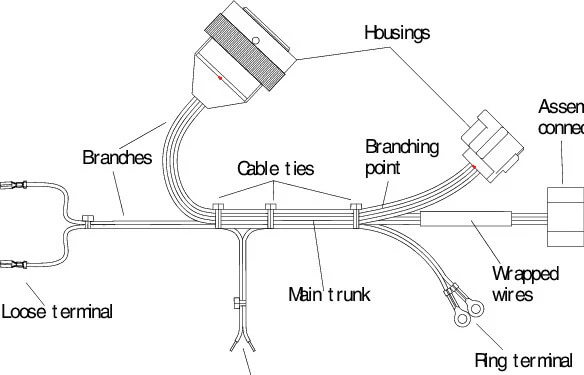

what are the components of a automotive wiring harness?

Automotive Wiring Harnesses ≈ Conductors + Terminals + Connectors + Sleeves + Tapes + Holders + Labels + Modules.

These components work together to form a set of high-performance, easy-to-assemble, maintainable in-vehicle electrical connection system. At the same time, it meets the requirements of high temperature resistance, waterproof, anti-interference, anti-vibration and other automotive grade reliability.

A complete automotive wiring harness product consists of the following components:

- Wires / Cables: Used for transmission of power and signals, is the core carrier of the wire harness.

- Terminals: Installed at both ends of the wire, used to crimp with the connector internal metal parts to achieve reliable conduction.

- Connectors: Plastic housings used to interface a wire harness with electronic components, controllers, or other wiring harnesses.

- Sleeves & Corrugated Tubes: Used to protect wire harnesses from abrasion, vibration, oil, heat and other environmental effects.

- Tape & Wrapping Material: Used for wire harness branch fixing, insulation wrapping, waterproof sealing and noise suppression.

- Clips, Grommets, Brackets: Used to secure wiring harnesses to the frame or body parts to prevent loosening, pulling or fraying.

- Labels & Markings: For visual identification of wiring harness PIN numbers, connection points, applications, versions, etc..

- Junction Blocks / Splice: For centralized connection of multiple circuits or extensions to other subsystems to simplify the wiring structure.

what is the difference between a wire and a automotive wire harness?

Although both single conductors and car wiring harnesses are essentially used for electrical transmission, there are significant differences in their structure, function, manufacturing methods, and purpose of use.

It can be simply understood that the conductor is equal to the wire itself, which can only be connected to a single circuit. A harness, on the other hand, is equivalent to multiple wires + a structural system, which is a complete electrical connection solution. A single wire is one of the components of a wiring harness, while an automotive wiring harness is a set of multiple wires that are functionally integrated, wrapped, and standardized to form a system-level product.

Here is a brief comparison between Single Wire and Automotive Wiring Harness.

| Item | Single Wire | Automotive Wiring Harness |

|---|---|---|

| Definition | A single conductor with insulation | A bundled system of multiple wires with terminals, connectors, and protection |

| Structure | Simple, only one wire | Complex, includes wires, connectors, terminals, tubes, labels, etc. |

| Functionality | Transmits power or signal on a single path | Integrates multiple functions, enabling power + data transmission |

| Maintainability | Easy to install or replace individually | Modular and pluggable, allows efficient system-level maintenance |

| Manufacturing | Cut and strip; often manual | Involves cutting, crimping, sleeving, bundling, testing |

| Application | Small-scale or single-point connections | Used for entire vehicle electrical systems, mass production compatible |

| Connection Method | Often soldered or manually wired | Uses terminals + connectors, plug-and-play design |

| Typical Example | One wire powering a bulb or sensor | A full set of cables connecting ECU, lighting, dashboard, sensors, etc. |

types of automotive wiring harnesse

1. Engine Wiring Harness

The engine wiring harness is mainly used to connect the engine control unit (ECU) with fuel injectors, ignition system, temperature sensors, air flow meters and other core components. Its main role is to ensure engine performance, fuel efficiency and emission control. During operation, the engine wiring harness needs to withstand high temperature and high vibration environment, so it has the performance of heat-resistant and flame retardant, strong anti-interference and stable conduction.

In gasoline, diesel and hybrid power systems, the engine wiring harness has a complex structure and many branches, which is one of the most difficult types of wiring harnesses for the whole vehicle. Its stability is directly related to the power output of the vehicle and operational safety, so it must use high reliability terminals, high temperature wire and shielding design.

Typical use of parts:

- Ignition coil

- Air flow meter

- Throttle position sensor

- Crankshaft/camshaft position sensor

- Injector Plugs

Examples of usage scenarios:

- Gasoline engine control system

- Solenoid valve control for turbocharging system

- Cold start temperature compensation module connection

2. Body Wiring Harness

The wiring harness connects the external function modules of the whole vehicle, such as headlights, taillights, turn signals, windshield wipers, door locks, center control, mirrors, etc., which is the “peripheral network” in the electrical control system of the whole vehicle. It is a “peripheral network” in the electrical control system of the whole vehicle. It is wired along the main beam of the body, the floor and the roof, with a wide range of branches and a flexible structure.

Therefore, these wiring harnesses need to have good weather resistance, corrosion resistance and waterproof ability. Its modular design helps to improve the efficiency of the whole vehicle assembly and ensures error-free assembly process by means of anti-defective plugs and labeling.

Typical use of parts:

- Headlights / Tail Lights / Fog Lights

- Heated and electrically adjustable mirrors

- Power door locks / door switches

- Electric Glass Lifter

- Trunk opener

Example of usage scenarios:

- Door control module wiring for four-door model

- LED headlight power and signal control

- Reversing radar and reversing lights share the same wiring harness

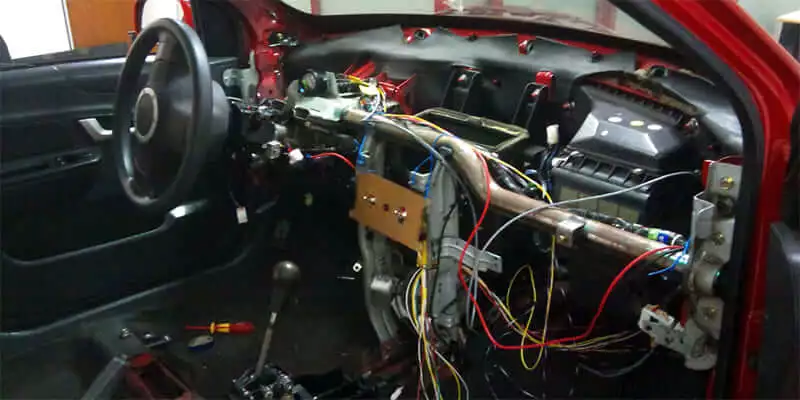

3. Dashboard Wiring Harness

The instrument panel wiring harness is located inside the cockpit, connecting the combination instrument, air conditioning controller, center display, key switches, audio system and other equipment. It is an important pathway to realize the functional operation and information display in the vehicle. It usually has a compact structure and dense wiring, which is easy to integrate and install.

Due to the limited space in the cockpit, the wiring harness flexibility, dimensional accuracy and EMC anti-interference requirements are high. Instrumentation harnesses are also often integrated with CAN and LIN buses, assuming the responsibility of module communication, which is the basic bridge for intelligent cockpit electronic systems.

Typical use of parts:

- Combination Instrument

- Multi-function steering wheel switch

- Air conditioning temperature control panel

- USB / Audio Interface

- In-vehicle center control panel

Example of usage scenarios:

- CAN signal connection between center screen and T-Box

- Connection of the instrument data bus to the OBD interface

- Wiring harness for automatic air conditioning control system

4. Door Wiring Harness

The door wiring harness is dedicated to connecting electronic devices inside the door, including power window lifters, center locks, welcome lights, door speakers, mirror heating and folding controls, etc. It connects to the main harness through flexible bellows. It is connected to the main wiring harness through flexible bellows, and needs to withstand the tugging and bending of the door body when it is repeatedly opened and closed.

The design of the door wiring harness needs to take into account the flexibility, waterproof and abrasion resistance, and some high end models also have anti-pinch control signals and side airbag sensor cables. The plug design needs to have the positioning of anti-dumbness and high insertion and extraction life, in order to protect the long-term stable operation of the door system.

Typical use of parts:

- Power window lift motors

- Door lock actuators

- Door speakers

- Door Lamps / Welcome Lamps

- Airbag sensor cable (side airbag)

Example of usage scenarios:

- Driver’s door control panel to control all windows

- Multi-function speaker wiring

- Synchronized control of welcome lights on higher trim levels

5. Battery / High Voltage Harness

In new energy vehicles and hybrid vehicles, the high-voltage wiring harness is used to connect the power battery, BMS, motor controller, OBC (on-board charger) and DCDC converter, and to transmit high-voltage power from 400V to 800V. It is the most central and critical part of the vehicle’s high-voltage electrical system.

This type of wiring harness needs to use high insulation, high voltage, heat-resistant, flame-retardant special materials, with arc-proof, shock-proof design, and support for high-voltage interlock (HVIL) function. Its reliability is directly related to the safety performance of the whole vehicle, and it needs to pass the strict pressure resistance, temperature rise and electromagnetic compatibility test.

Typical use of parts:

- Power Battery Module

- DCDC Converter

- On-Board Chargers (OBC)

- High Voltage Distribution Unit (PDU)

- BMS Voltage and temperature monitoring line set

Example of usage scenarios:

- 400V~800V High Voltage Battery Main Cable

- Harness pathway from charge gun to battery pack

- High Voltage Interlock HVIL Interface Connection

6. CAN / LIN / Ethernet Harness

Communication harnesses are used to connect data channels between electronic control modules of the whole vehicle, including CAN bus, LIN bus and Automotive Ethernet, which can realize high-speed transmission of real-time control signals, diagnostic information, vehicle status, etc. These harnesses usually adopt twisted shielded structure with good anti-interference and signal integrity, which requires termination accuracy and consistency of wire length.

These harnesses are usually constructed with twisted shielded wires, which provide good interference immunity and signal integrity. They require high termination accuracy and line length consistency, and are widely used for high-speed communication between controllers such as autopilot, T-Box, instrument panel, and power system.

Typical use of parts:

- CAN main/branch cable

- LIN node connection cable

- Communication adapter connector

Example usage scenario:

- Automatic Driver Assistance System (ADAS) module communication

- Bus wiring between infotainment system and audio module

- Instrument and engine data synchronization interface

7. Sensor Wiring Harness

The sensor harness connects all kinds of vehicle sensors, such as camera, ultrasonic radar, rain/light/temperature sensors, tire pressure monitor (TPMS), RPM/acceleration sensors and so on. This type of automotive wiring harness is mainly responsible for collecting environmental or vehicle status signals and feeding them back to the main controller.

These wiring harnesses are usually fine gauge, small connector, high precision wiring, small installation space, high anti-vibration and EMI shielding requirements. Their stability has a direct impact on the response speed and reliability of automatic driver assistance systems (ADAS) and body control systems.

Typical use of parts:

- Temperature sensors

- Camera Module

- Speed/revolution sensors

- Barometric pressure/humidity sensor

Example usage scenario:

- Rain sensor connected to wiper control module

- Reversing camera video signal transmission

- Tire pressure monitoring system (TPMS) wiring

what are the desigh requirements for automotive wiring harnesses?

An excellent automotive wiring harness design must be balanced in the six dimensions of safety, function, structure, manufacturing, environment, and regulations in order to truly realize the engineering goals of high reliability, easy manufacturing, and easy maintenance.

Therefore, the design of automotive wiring harness is not just a simple matter of “connecting wires”, but also involves the comprehensive consideration of vehicle architecture, electrical safety, assembly process, environmental adaptability and standards compliance. A reasonable wiring harness design can effectively reduce the electrical failure rate of the whole vehicle, improve assembly efficiency, and ensure stable operation under long-term use.

When designing automotive wiring harnesses, the following factors need to be considered:

- Function and circuit logic

- Wiring path and space layout

- Material selection

- Environmental suitability

- Standards and regulatory compliance

- Terminal and connector mating

- Manufacturing and assembly manufacturability

- Identification and Traceability

Element 1. Function and circuit logic

Before designing a set of automotive wiring harnesses, the first task is to clearly define the function of each wire. For example, does it carry power? Ground? Signal? Or is it a bus communication line? Different functions determine the wire diameter, voltage level, grounding method, and whether shielding is required.

- Power lines need to meet the current carrying capacity, to avoid overheating or excessive voltage drop.

- Signal lines are concerned with transmission stability, electromagnetic interference (EMI) and termination.

- Communication lines (e.g. CAN, LIN, Ethernet) have strict requirements for pair length, impedance, and matching.

💡 The designer needs to comb through the signal paths, module locations, interface numbers, and PIN definitions according to the circuit diagram to ensure that all electrical channels are closed without error.

Element 2. wiring path and space layout

It is important to note that the wiring path of the car harness should be as short, clear, safe and easy to install as possible. In complex models, the wiring harness needs to traverse multiple areas such as the engine compartment, instrument panel, doors, floor, etc. These spaces are variable, restricted, and susceptible to heat sources, moving parts, vibration sources, and so on.

Design should be considered:

- Minimum bending radius, wire length, allowances (for easy plugging and unplugging)

- Avoid high temperature (e.g. exhaust pipe), high vibration (engine mount) areas

- Make full use of the car body structure for fixed point planning, to avoid wiring harness overhangs

- Reasonable wiring when there are too many branches, to prevent cross-tangling affecting assembly efficiency.

3D simulation (e.g. CATIA) is usually required to verify the feasibility of wiring in advance.

Element 3. material selection

Material selection determines the durability, safety and cost control of the harness. Designers need to select the appropriate wire, insulation, covering and connector materials according to the usage environment:

- Wire insulation: PVC (conventional), XLPE (high temperature), TPE (flexible)

- Sheathing materials: bellows (PE, PP), glass fiber sleeve, cloth-based tape, foam pads

- Connector shell: PA66, LCP, temperature resistance, flame retardant, anti-aging requirements

- Metal terminals: copper / tinned copper, gold-plated terminals for oxidation resistance, frequent plugging and unplugging scenarios

Material selection should comply with RoHS / REACH / UL94V-0 flame retardant grade requirements, while also taking into account the cost and processability.

Element 4. environmental suitability

Automotive wiring harnesses are often exposed to extreme environments. For example, they are used in areas such as the engine compartment, chassis, and inside the doors. These areas are constantly exposed to temperature, water vapor, dust, oil, vibration, and ultraviolet rays, and therefore have stringent requirements for wiring harnesses. Wiring harnesses in different areas should have the corresponding environmental adaptability:

- Temperature rating: ≥125°C or even 150°C in the engine compartment.

- Waterproof: IP67 / IP69K for exposed areas.

- Resistance to vibration: Plug connectors are often designed with locking clips and anti-loosening fixings.

- Resistance to EMI interference: High-speed signal lines are shielded and shielded connectors are used.

💡 The durability of the wiring harness should be able to meet the vehicle life of more than 10 years, to maintain the stability of mechanical and electrical properties.

Element 5. standards and regulatory compliance

The standards for automotive wiring harnesses are very stringent. Therefore, wiring harnesses used in automobiles are subject to a number of international standards and regulations. This ensures traceability and export compliance in terms of safety, environmental protection and quality.

Common standards include:

- ISO 6722 / ISO 19642: Standard for the construction and performance of automotive wires.

- SAE J1128 / J1939: North American Commercial Vehicle Cable Code

- IATF 16949 / ISO 9001: Quality Management System Certification (required for manufacturers)

- RoHS / REACH: EU environmental standards banning the use of hazardous heavy metals

- IMDS (International Material Data System): Registration in the Vehicle Material Traceability Database

Element 6. terminal and connector mating

The choice of terminals directly affects the conductivity reliability and service life of the harness. The connector must meet the design requirements of electrical parameters, current demand, waterproof rating and the number of plugging and unplugging.

Attention should be paid to the design:

- Whether the plug structure matches with the matching module interface (male/female, PIN number, KEY bit)

- Whether the plug life is up to standard (≥ 500 times as a general requirement)

- Small contact resistance (typical value < 10 mΩ), moderate contact force

- Whether there is anti-dull structure, anti-loosening design, locking / snap safety mechanism

- Whether the need for terminal secondary lock / pressure piece to ensure pin positioning

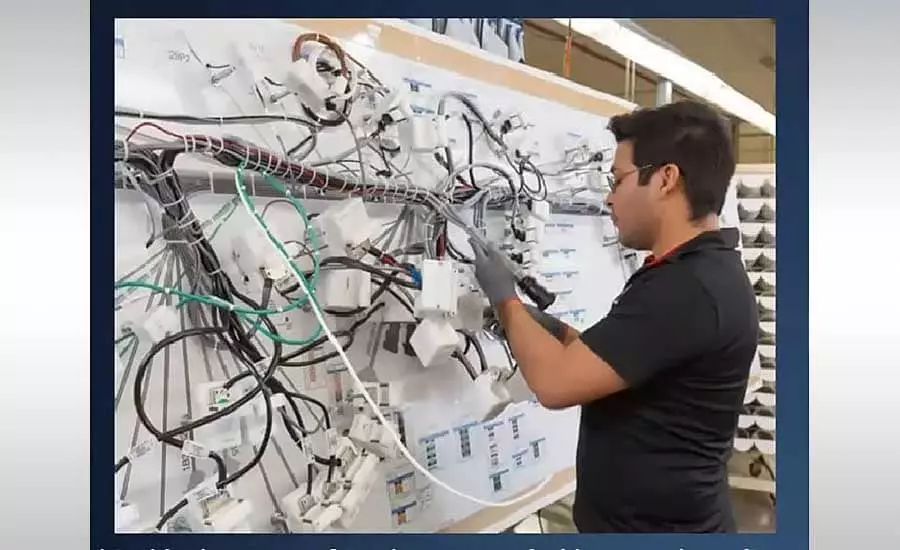

Element 7. manufacturing and assembly manufacturability

The design of automotive wiring harnesses should not only be “usable”, but also “good”. Good design should consider the standardization, simplicity and consistency of the manufacturing process, reducing the difficulty and error rate.

Focus on:

- Whether the branch is easy to assemble in the nail plate, the alignment is reasonable, no crossing

- Whether the wiring length is marked and the color identification is clear

- Whether it is suitable for automatic crimping machine, automatic wire cutting machine and other equipment processing

- Whether the wrapping method is standardized: tape/heat-shrinkable tube/corrugated tube is uniform or not

- Whether to support modular assembly, quick replacement

Element 8. identification and traceability

For ease of assembly, testing, maintenance and quality traceability, the harness design must include a comprehensive and clear identification system:

- Each wire should be color-coded or numbered with heat transfer marking

- Each branch should be labeled (barcode, QR code, PIN number)

- Plugs should be labeled with part number, orientation, and plugging instructions (to prevent misplugging).

- Corresponding engineering data: circuit diagrams, PIN definition table, BOM, drawing number, change records, etc.

💡 All markings should be heat-resistant, not easy to fall off, and meet the needs of the entire vehicle life cycle use.

Problems caused by faulty car wiring harnesses

In the automotive electrical system, the wiring harness is the core connection pathway, once the failure occurs, it may lead to abnormal operation of the whole vehicle or even safety hazards. This causes various problems. The common fault problems are as follows:

- Engine shutdown

- Ignition failure

- Failure of electrical components

how long does a car wiring harness last?

Automotive wiring harnesses typically have a service life of about 10 to 15 years, which is designed to be consistent with the life cycle of the vehicle. However, the actual service life is affected by a variety of factors, some harnesses can last more than 15 years under normal conditions, while in harsh environments they may deteriorate or fail within 5 to 8 years.

can a car wiring harness be repaired?

Automotive wiring harnesses are repairable in the event of minor damage. Examples of problems include localized wire breaks, loose plugs, worn sheaths, or poor terminal contact. These problems can usually be repaired by soldering, replacing the terminals, re-crimping or wrapping to restore normal function. This type of localized repair is applicable to non-critical systems, and has a certain degree of economy and maneuverability, especially suitable for older models or non-core component wiring problems.

However, if the wiring harness is seriously damaged, such as the main trunk line burned, high-voltage system cable broken, critical modules (such as airbags, ABS) line damage, or water, rust, short circuit and other safety hazards, it is recommended that the whole replacement of the original wiring harness assembly. This is because such problems, once improperly handled, may bring about electrical failures or even vehicle safety risks. Repair or replacement should be assessed on a case-by-case basis and operated by professionals to ensure long-term stable operation of the system.

custom automotive wiring harness for your car business from manufacturer

When your vehicle needs to be upgraded due to an aging or damaged wiring harness, choosing a new set of automotive wiring harnesses is the key to ensuring the safe operation of the entire vehicle. Whether you need to replace the standard trunk harness, door control harness, or customize special high-voltage cables and sensor branches. We recommend that you prioritize high-quality wiring harnesses that comply with automotive standards, are structurally matched, crimped accurately, and protected. In addition to this, you need to have full process support from an experienced supplier.

Linkwings, as a professional automotive wiring harness manufacturer, provides one-stop service from selection suggestion, drawing design, sample proofing to mass delivery. We support OEM / customized orders with IATF 16949 quality system certification and rich industry experience. So we can quickly match the right wiring harness solution to your vehicle or project. Contact us today for technical support and a quote to help keep your vehicle systems safe.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In