What is Crimping Wires?What Does it Mean to Crimp a Wire?

Home » What is Crimping Wires?What Does it Mean to Crimp a Wire?

In the world of electrical wiring, creating reliable and long-lasting connections is an absolutely core task. Whether you are assembling a car, a household appliance, a solar system or industrial control equipment, you will eventually need to connect the wires securely to terminals or connectors. This is where crimping comes in handy – it’s a fast, efficient and professional way to make connections. No soldering is required, yet solid electrical performance is achieved.

So, “What does crimping wire really mean?”

Why is crimping so widely used in today’s electrical connections? What exactly are its advantages over traditional welding and screwing methods?

This post will provide you with systematic answers to everything you need to know about crimping, including the definition of crimping, how it works, how it compares to soldering, and the proper procedure.

Whether you are a DIY enthusiast just starting out or an experienced engineer, this guide will help you fully understand what is crimping wires? What does it mean to crimp wire.

What is Crimping Wires?

Crimping is an electrical connection technique that mechanically joins wires to terminals. It does not use solder or adhesive, but relies on the application of pressure to make a strong, reliable, conductive physical connection between the metal conductor and the metal terminal. During the crimping process, the conductor is stripped of its outer insulating skin and inserted into the end of the terminal. Then through the special crimping tools (such as crimping pliers) on the terminal compression, so that the wire copper wire embedded in the terminal cavity and deformation lock.

This process is actually a kind of “cold welding” – although there is no high temperature or melting, but through the physical deformation of the two metal materials to achieve a close fit between the two and the electronic level of contact. This is a fast and efficient connection with excellent tensile strength, vibration resistance and electrical stability. It is therefore commonly used in applications where volume manufacturing and electrical reliability are critical.

The essential advantages of Crimping Wires:

- Forms tight metal-to-metal contact and is highly conductive

- No heat required, no damage to insulation or thermal faults

- Suitable for high volume operations with a high degree of automation

- Consistency, virtually identical from one connection to the next, for easy quality control

- Conforms to international standards (e.g. IPC/WHMA-A-620) for a wide range of industrial, automotive and aerospace applications.

How do Crimping Wires Work?

The working principle of crimping wires can be summarized in two points:

- Metallic deformation → electrical conduction: copper wire and terminals are pressed together in a microscopic scale to form a solid conduction path.

- Mechanical locking → tensile and vibration resistance: interlocking between materials, without welding can withstand external forces, temperature differences and vibration environment.

In practice, the crimping process usually consists of the following key links:

Step 1: Physical contact to form a conductive path

The conductor is first stripped of its outer insulation before crimping, and the bare metal core is inserted into the metal tube or U-groove of the terminal. When the terminal is squeezed with crimping pliers, the terminal metal undergoes permanent plastic deformation, shrinking the internal space and wrapping around the wire.

In the process, the copper wire and the terminal are pressed so tightly against each other that a microscopic metallic embedding is formed. The result is an electrical connection with low contact resistance and high conductivity. This contact is far more stable than a simple “lap” and is resistant to oxidation and vibration.

Step 2: Mechanical locking ensures tensile strength and durability

In addition to the electrical connection, crimping also achieves mechanical locking. With the right crimping mold and force control, the copper wire “bites” and locks inside the terminal, forming a strong physical anchorage point. This structure has a strong resistance to tension and vibration, and is not prone to loosening or breaking in transportation, vibration or high temperature environments.

Some terminals also have an “insulation crimp zone”. Used to clamp the outer skin of the conductor at the same time, to enhance the overall distribution of stress, to prevent stress concentration in the root of the conductor and lead to breakage.

Step 3: Ensuring Consistency and Repeatability

One of the greatest advantages of crimping is its high consistency. With the use of suitable crimping dies and standard process parameters, the crimping effect can be reproduced on almost every wire. For applications requiring mass production and high quality consistency, such as automotive wire harnesses and industrial cables, crimping becomes the preferred solution.

Why Use Crimping Wires Instead of Other Wire Connection Methods?

Among the various electrical connection methods (e.g. soldering, screwing, plug-in connections, etc.), crimping is considered to be one of the most efficient, reliable and reproducible connection methods.

Crimping can be well adapted to the modern industrial needs of wire connection. It not only meets electrical performance requirements, but also offers significant advantages in terms of productivity, environmental protection and safety. For this reason, crimping has become the standard for a wide range of connection technologies worldwide, from automotive main harnesses to medical devices to aerospace electronics.

The reasons for using crimp connections can be understood in the following key aspects:

⚡ 1. Stable electrical performance, excellent conductivity

Crimping through high-strength mechanical extrusion, in the copper wire and metal terminals between the formation of close metal contact, greatly reducing the contact resistance. This “cold welding” structure can not only achieve excellent conductivity, but also effectively prevent circuit failures caused by oxidation or poor contact. This makes it particularly suitable for low-voltage signals, high-current paths, and critical control lines.

🔩 2. High mechanical strength and vibration resistance

Crimped connections have excellent tensile strength and vibration stability. In practical applications, such as automotive wiring harnesses, motor control lines, railroad signaling systems, etc., the cable connection part is required to withstand long-term vibration, repeated bending and temperature fluctuations. The crimped structure ensures that the connection points will not come loose or break, making it an ideal connection for extreme working conditions.

🔧 3. Fast process for batch and automation

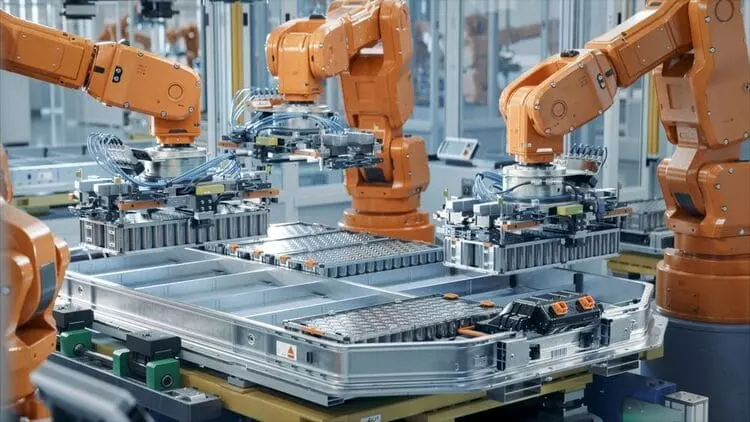

Compared to soldering, crimping requires no heat, solder or flux and is fast, making it particularly suitable for automated production lines. Modern crimping equipment (e.g., automated crimping machines such as Komax, Schleuniger, etc.) can strip, crimp, and inspect multiple wires in seconds, dramatically increasing throughput and consistency. This is especially critical for high-volume orders that require efficient delivery and stable quality control.

✅ 4. High connection consistency and quality control

With standardized crimping dies and process parameters, each crimp can achieve nearly consistent crimp depth, sealing and fill ratio. In contrast to soldering, which is subject to temperature, solder quality and operating experience, crimping is more standardized, traceable and compliant with international quality systems such as ISO and IPC. It is therefore suitable for any product area where consistency and verifiability are required.

🔥 5. Safer, more environmentally friendly

The crimping process does not use open flame, molten tin or volatile flux, smoke-free and non-toxic, suitable for environmental protection and clean production workshop use. And the connection structure after crimping is solid and reliable, which is less likely to cause safety hazards due to human error. This is especially important for new energy vehicles, high-voltage cables, rail transportation and other high-security products.

Crimping Wires vs Soladering Wires: What's the Difference?

| Aspect | Crimping | Soldering |

|---|---|---|

| Connection Method | Mechanical compression → cold-weld metal contact | Melting solder → metallurgical bond |

| Tools Required | Crimping pliers, automatic crimping machines | Soldering iron, solder wire, flux |

| Speed | Fast, ideal for mass production | Slower, requires heating and cooling time |

| Electrical Conductivity | Low contact resistance, highly consistent | Good, but depends on solder joint quality |

| Mechanical Strength | High, strong pull and vibration resistance | Brittle joint, prone to cracking under stress |

| Consistency & QC | High repeatability, automation-friendly | Manual skill-dependent, variable results |

| Environmental Impact | No heat, no fumes, cleaner process | Produces smoke, lead-based solder may be toxic |

| Typical Use Cases | Automotive harnesses, industrial connectors, aerospace, cable assembly lines | Small repairs, DIY electronics, PCB soldering |

Tools and Materials for Crimping Wires

To complete a standard, safe and reliable crimping operation, you must use appropriate crimping tools and electrical connection materials. The following is a classification of common tools and materials, covering all needs from entry-level DIY to industrial-level manufacturing environments.

Crimping Tools

- Crimping Pliers: The most basic crimping tool for home repairs, light engineering.

- Automatic Crimping Machines: for industrialized mass production.

- Terminal Positioner / Fixture: For accurate positioning of small sized terminals and wires.

- Wire Stripper: For precise removal of wire insulation without damaging the copper wire.

- Cable Cutter: For flat cutting of wires.

- Heat Gun: For shrinking heat shrink tubing after crimping.

Crimping Materials

Terminals

- Open Barrel Terminals: Used for automotive wiring harnesses, often used with automatic crimping machines.

- Closed Barrel Terminals: Commonly used in general-purpose connections, manual crimping is applicable.

- Pre-Insulated Terminals: Red/blue/yellow insulating shell for easy identification and protection.

- Ring Terminals / Tab Terminals / Pin Jacks: Various types of terminals are available according to function and installation configuration.

Wires

- Single or multi-core copper wires, depending on the current, voltage and application (e.g. AWG18, AWG14, AWG10).

- Some applications also require shielded wires, high temperature resistant wires, silicone wires, double insulated wires.

Heat Shrink Tubing / Electrical Tape

- Used for external wrapping after crimping to enhance waterproof, dustproof and corrosion resistance.

- Commonly used in automotive, electric vehicles, outdoor equipment and other high-reliability scenarios.

Marking Labels (Wire Markers / Flag Labels)

- For marking wire numbers, circuit numbers or plug-in positions

- Inkjet, thermal transfer and handwriting support

Typical Applications of Wire Crimping

Crimping has become one of the most mainstream wire connection methods in modern electrical engineering precisely because it has a series of advantages such as high efficiency, stability, vibration resistance and easy mass production. It is therefore widely used in a variety of electrical systems from civil electronics to high-end industry. The following are a few of the main application areas of crimping technology:

Application 1 : Automotive Wiring

In automotive manufacturing, almost all wiring harnesses are connected using crimped connections. From engine compartment backbone harnesses and dashboard control wires to control circuits in door locks, headlights, ABS, and air conditioning systems, they all rely on crimped terminals for highly reliable connections. Crimping can maintain stability under extreme operating conditions such as vibration, high temperature, humidity and heat, and is the connection technology preferred by OEMs and Tier 1 suppliers.

Application 2 : Industrial Control Systems

In automated production lines, mechanical equipment, PLC systems, crimping is used for sensor connection, motor control, I / O module wiring, etc.. It can ensure accurate signal transmission and safe operation of equipment. Industrial terminals usually use pin type (open barrel), M12/M8 waterproof connectors and other structures, which require precise crimping operations.

Application 3 : Aerospace & Railway

Aerospace and rail systems require high reliability of wiring harnesses that are vibration, corrosion, and interference resistant. Crimping can provide stable contact resistance and resistance to mechanical shock. At the same time to meet the military standards, aviation standards (such as MIL-Spec, AS22759) on the connection performance of the strict standards.

Application 4 : Home Appliances & Electronics

From washing machines, refrigerators, water heaters to televisions, stereos, and desktops, most of the power, control, and signal wire connections within home appliances use pre-insulated crimp terminals. This facilitates quick assembly, maintenance and module replacement. Crimping wires are used a lot in volume manufacturing and OEM assembly.

Application 5 :EV, Solar, ESS

In new energy vehicles, photovoltaic power generation, energy storage systems, crimping is used for power cables, control wires, busbar connection. These applications require crimping structures that can withstand high voltages and currents. High voltage crimp terminals (HV terminals) and multi-stranded copper braid need to use professional crimping molds to meet safety and thermal stability.

6. Medical Devices

Miniature connectors within medical devices are typically miniature crimp terminals that require low contact resistance, immunity to interference and biocompatibility. The precision and consistency of crimping technology meets the stringent “zero failure” requirements of medical devices.

Application 7 : Telecom & Data Systems

From RJ45 network cables and shielded signal cables to fiber optic composite cables, shielded crimp connections are used extensively in communications systems. Because it can ensure EMI suppression, signal integrity and data security. In data centers, base stations, switching equipment, etc., crimping has been one of the standard processes.

Crimping Is the Gold Standard for Modern Electrical Connections

Through this article, we have comprehensively introduced the definition, working principle, advantages, common tools, common errors and typical application areas of Crimping Wires. As you can see, Crimping is no longer a simple manual connection method, but a standardized, industrialized and highly reliable connection process. And is widely used in automotive manufacturing, industrial control, communication equipment, new energy, medical electronics and other key areas.

Compared with traditional soldering or screw wiring, Crimping is faster, more stable and more suitable for large-scale manufacturing and long-term use. It not only provides good electrical performance, but also has excellent vibration resistance and environmental adaptability, is the modern electrical system in the “invisible but critical” core technology.

📌 As a leading crimping wire manufacturer,Linkwings provides full-process wire harness manufacturing services from wire cutting, crimping, assembly, testing, packing to shipping. We also support high volume production, small batch customization, OEM cooperation, drawing optimization and rapid prototyping. Whether you are developing a new product or optimizing an existing harness solution, we can support you.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In