When you search for “what is flat cable,” you are usually looking for its definition, structure, and common applications. A flat cable is a type of cable that consists of multiple conductors arranged in parallel and enclosed in insulating material to form a ribbon-like structure. This type of cable is commonly used in computers, printers, home appliances, and automotive electronics. Compared to traditional round cables, it offers unique advantages in terms of space savings, neat wiring, and stable signal transmission. As a result, it has become an indispensable connection method in modern electronic and industrial equipment.

What is Flat Cable?

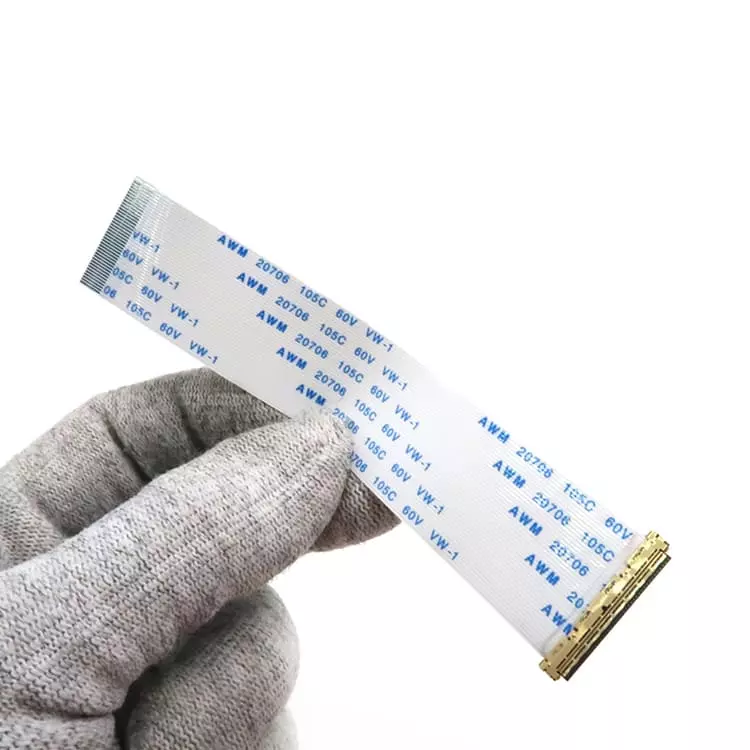

As the name suggests, a Flat Cable is a type of cable with a flat, ribbon-like shape. It consists of multiple conductors arranged in parallel at specific intervals, which are then enclosed by one or more layers of insulating material to form a ribbon-shaped cable. This unique structural design gives the Flat Cable an appearance resembling a “ribbon,” hence its common alternative names in practical applications: Ribbon Cable or Flexible Flat Cable (FFC).

Compared to traditional round cables, the most notable feature of Flat Cable is its ordered arrangement, uniform thickness, and ability to be folded and bent. This structure makes it easier to route cables in confined spaces while ensuring consistent electrical performance between multiple conductors, thereby reducing the risk of signal interference and crosstalk.

Structure and Working Principle of Flat Cable

The most distinctive feature of flat cable is that multiple conductors are arranged in parallel at fixed intervals and covered with an insulating layer to form a ribbon structure. This special geometric shape not only changes the appearance of the cable, but also directly affects its electrical performance and mechanical characteristics.

Structural Composition

Conductor

- Common materials: bare copper, tin-plated copper, and sometimes silver-plated copper wire to improve conductivity.

- Arrangement: Multiple conductors are strictly arranged in parallel at equal intervals, with standard spacing (pitch) typically set at 0.5mm, 1.0mm, 1.25mm, etc.

- Function: Provides a pathway for current or signals.

Insulation Layer

- Common materials: PVC (polyvinyl chloride), PET (polyester), PI (polyimide).

- Features: Heat-resistant, wear-resistant, flame-retardant, and prevents short circuits between adjacent conductors.

- High-end products may use low-dielectric constant materials to reduce signal loss.

Shielding Layer

- In high-frequency or high-interference environments, some flat cables may include a metal braided layer or aluminum foil shielding layer.

- Function: Reduces electromagnetic interference (EMI) and ensures the stability of high-speed signal transmission.

Outer jacket

- In harsh environments such as industrial or automotive applications, an outer jacket with wear-resistant, oil-resistant, or flame-retardant properties may be added over the insulation layer.

Working Principle

The operating principle of flat cables is similar to that of round cables, both relying on conductors to transmit current or signals. However, due to their flat arrangement structure, they offer the following key characteristics:

- Signal consistency: All conductors are parallel and equidistant, resulting in nearly identical signal path lengths.

- Low Crosstalk: The fixed spacing between adjacent conductors results in more uniform electromagnetic field distribution.

- High Flexibility and Foldability: Especially for FFC (Flexible Flat Cable), it can be repeatedly bent and is suitable for moving parts.

- High Space Utilization: The flat structure allows Flat Cable to be routed in extremely narrow spaces.

- Shielding and Signal Integrity: When a shielding layer is added, Flat Cable significantly reduces EMI/RFI interference, ensuring signal integrity in complex electromagnetic environments.

Flat Cable vs Round Cable

When selecting cables, one of the most common questions engineers and users ask is: What exactly is the difference between flat cables and round cables? Both types have their own advantages in terms of structure, performance, and application scenarios. Below, we will help you better understand the differences between the two through a comparison.

| Feature | Flat Cable | Round Cable |

|---|---|---|

| Structure | Conductors arranged in parallel, ribbon-like | Conductors bundled together with a round jacket |

| Wiring Flexibility | Ideal for tight spaces, neat routing | Suitable for long distances and complex paths |

| Signal Performance | Low crosstalk, high signal consistency, good for high-speed transmission | Random conductor arrangement, more skew and delay |

| Mechanical Strength | Flexible but lower tensile strength and wear resistance | Stronger, more durable, better tensile strength |

| Heat Dissipation | Even conductor distribution, better heat dissipation | Bundled conductors, weaker heat dissipation |

| Shielding Capability | Can be designed with specific EMI shielding layers | Relies on outer jacket and braided shielding |

| Common Applications | Laptops, displays, printers, automotive dashboards | Power transmission, motors, appliances, industrial control |

| Cost | More complex manufacturing, relatively higher cost | Mature process, more cost-effective |

Conclusion

- Flat Cable: Suitable for applications with limited space and requiring high-speed signal transmission, such as laptops, displays, and automotive electronics.

- Round Cable: More suitable for long-distance transmission, high current/power, industrial environments, and higher mechanical strength.

In actual engineering applications, Linkwings often customizes hybrid solutions for customers: for example, using Flat Cable inside equipment to ensure compactness and signal stability, and Round Cable on the outside to ensure durability and power transmission.

Common Types of Flat Cables

Although flat cables are all ribbon-shaped, there are several common types based on their structure, manufacturing process, and application scenarios. These include ribbon cables, FFC (flexible flat cables), and FPC (flexible printed circuits). Each type has its own unique characteristics and applications.

Ribbon Cable

Ribbon cable is the most traditional type of flat cable, typically consisting of multiple parallel conductors enclosed within a single layer of insulating material. Its appearance resembles a ribbon, hence the common name “ribbon cable.”

Its advantages include mature manufacturing processes and low cost, making it suitable for mass production. It is commonly found in early computer IDE hard drive interfaces, printers, and internal connections in home appliances.

Ribbon cables are more suited for transmitting low-frequency signals or power currents and are typically used in conjunction with IDC (Insulation Displacement Connectors).

FFC(Flexible Flat Cable)

As the demand for lighter, thinner, and more flexible electronic products has grown, FFC (flexible flat cable) has emerged. This type of cable consists of multiple copper conductors sandwiched between two layers of insulating film, with a thickness often less than 0.3mm. It is extremely lightweight, flexible, and can be repeatedly bent.

The spacing between conductors (pitch) is highly standardized, with common specifications including 0.5mm, 1.0mm, and 1.25mm. This design supports higher data transmission rates while effectively reducing signal crosstalk.

.webp)

Today, FFCs can be found in a wide range of devices, including laptops, LCD displays, printers, and automotive infotainment systems.

.webp)

FPC(Flexible Printed Circuit)

In the high-end electronics and precision manufacturing sectors, FPC (flexible printed circuit boards) are widely used. Unlike ribbon cables and FFCs, FPCs are not simply parallel conductor arrangements but rather complex circuit patterns formed through etching or printing on flexible substrates such as polyimide (PI). They can achieve single-layer, multi-layer, or even three-dimensional folded designs.

They not only offer exceptional flexibility but also exhibit high-temperature resistance and chemical corrosion resistance. As a result, they are highly suitable for applications in smartphones, digital cameras, wearable devices, and medical electronics. Although they are relatively expensive, their customization capabilities and performance advantages make them nearly indispensable in high-precision electronic applications.

Where Flat Cables Are Used?

Flat cables are used in almost all key industries, including consumer electronics, automotive, industrial, medical, and aerospace. Each industry has its own challenges, and Linkwings can provide complete support ranging from standardized products to highly customized solutions, ensuring that customers obtain safe, reliable, and long-term stable cabling solutions in different environments.

- Consumer Electronics: Laptops, tablets, smartphones, televisions, printers, scanners, etc.

- Automotive Electronics: Central control displays, instrument panels, in-vehicle cameras, entertainment systems, intelligent driving sensors, etc.

- Industrial Automation & Robotics: Sensor and controller connectivity, robotic arm dynamic cabling, industrial printers, and CNC equipment.

- Medical Devices: Imaging diagnostic systems, monitoring instruments, surgical robots, and wearable medical devices.

- Aerospace & Defense: Flight control systems, satellite communication modules, and military portable electronic devices.

How to Choose Flat Cable?

In practical applications, selecting the appropriate flat cable is not simply a matter of “size matching.” Rather, it requires comprehensive consideration of electrical performance, mechanical reliability, environmental adaptability, interface compatibility, and international standard certification.

Factor 1. Number of Conductors and Pitch

Number of Conductors

- Determines how many signal or power lines a flat cable can carry.

- As few as 4 cores, or as many as 80 cores or even hundreds of cores.

- In consumer electronics, common configurations include 6-core, 12-core, and 24-core; in industrial equipment, configurations with 40 cores or more may be required.

Pitch (Center-to-center distance between adjacent conductors, unit: mm)

- Common specifications: 0.5mm, 1.0mm, 1.25mm, 2.54mm.

- 0.5mm: Commonly used in ultra-thin devices such as smartphones and camera modules.

- 1.0/1.25mm: Commonly found in laptop displays, printers, etc.

- 2.54mm: Traditionally used in ribbon cables, suitable for industrial equipment or power transmission.

Professional advice: In high-speed signal applications, a smaller pitch improves signal consistency but increases manufacturing difficulty and cost.

Factor 2. Voltage and current carrying capacity

Current capacity

- Depends on the cross-sectional area of the conductor (AWG, American Wire Gauge).

Example:

- AWG 28 (diameter approx. 0.32 mm) → Can carry ~1 A current

- AWG 24 (diameter approx. 0.51 mm) → Can carry ~2–3 A current

- AWG 20 (diameter approx. 0.81 mm) → Can carry ~5A current

Multi-strand twisted conductors are more flexible than single-strand conductors but have slightly lower current carrying capacity.

Voltage Rating

- Common rated voltages for ribbon cables: 30V–300V.

- FFC/FPC are primarily used for signal transmission and typically have lower voltage ratings (30V–60V).

- In industrial and automotive applications, higher voltage ratings must be selected if used for power supply.

Professional advice: Current-carrying capacity must have a margin of over 20% to prevent insulation aging due to heat buildup from long-term use.

Factor 3. Flexibility and bending life

Static wiring: Used in fixed installation scenarios (such as motherboard to daughterboard connections), only basic flexibility is required.

Dynamic wiring: Used in scenarios involving repeated movement (such as printer carriages and robot joints).

- FFC can withstand thousands to tens of thousands of bends.

- High-end FPC uses PI substrate, supporting millions of bends with a bending radius as small as 1mm.

Professional advice: The bending radius should be at least 6–10 times the cable thickness to extend service life.

Factor 4. Environmental Adaptability

Temperature Range

- PVC Insulation: -20°C to +80°C

- PET Insulation: -40°C to +105°C

- PI (Polyimide): -40°C to +125°C, with some military-grade variants reaching +200°C

Humidity and Water Resistance

- Generally, FFC/FPC does not have waterproof capabilities. For outdoor applications, a waterproof sleeve or sealant must be added.

Oil Resistance/Chemical Corrosion Resistance

- In industrial environments where exposure to lubricants or cleaning agents is possible, specialized sleeve materials must be selected.

Professional Recommendation: In harsh environments such as automotive or aerospace applications, materials with high-temperature resistance, moisture resistance, and corrosion resistance must be selected and validated through environmental testing.

Factor 5. Shielding and Signal Integrity

High-speed signals (HDMI, USB 3.0, LVDS, MIPI) have high EMI suppression requirements.

Common shielding methods:

- Aluminum foil shielding: Lightweight, suitable for medium and low frequency signals.

- Braided shielding: Stronger EMI resistance, commonly used in industrial control and automotive applications.

- Multi-layer shielding (composite structure): Used in high-end FPCs to ensure signal integrity.

Design considerations may also include symmetrical routing of differential signal pairs to further reduce crosstalk.

Professional recommendation: In applications with data rates exceeding 1 Gbps (e.g., 5G devices, high-definition displays), shielded flat cables must be used.

Factor 6. Connectors and Connection Methods

- Ribbon Cable → Commonly used IDC (Insulation Displacement Connector), suitable for mass assembly.

- FFC/FPC → Commonly used ZIF (Zero Insertion Force)/LIF (Low Insertion Force) connectors, easy to install and less prone to damage.

- High-end Customized Interfaces → Customizable non-standard pads or crimping structures can be designed to meet special mechanical space requirements.

Professional advice: When selecting a flat cable, it is essential to confirm the required connector type simultaneously; otherwise, there may be issues where the cable specifications are correct but installation is not possible.

FAQs

1. Can flat cables carry high currents?

Answer: Flat cables are more suitable for signal transmission and medium- to low-current applications. Their current-carrying capacity depends on the conductor gauge (AWG) and heat dissipation conditions. For example, a conductor with AWG 28 can handle approximately 1A of current, while AWG 20 can handle 3–5A. However, for high-current applications (such as motor drives), it is typically recommended to use round cable (Round Cable) or specially designed high-current FFC/FPC.

2. What is the difference between FFC and FPC?

Answer: FFC (Flexible Flat Cable) is made by sandwiching multiple copper conductors between insulating films, featuring a simple structure and lower cost, making it suitable for laptops, printers, displays, and similar devices. FPC (Flexible Printed Circuit) involves etching complex circuits onto a flexible substrate (such as PI polyimide), enabling multi-layer routing with higher flexibility and reliability. It is commonly used in smartphones, cameras, and medical devices.

3. How long is the bending life of flat cables?

Answer: It depends on the material and design. Ordinary PVC-insulated FFCs can withstand several thousand bends. High-performance FPCs use PI substrates and can withstand over a million bends, with a bending radius of less than 1 mm. In dynamic applications (such as robot or printer sliding parts), products that have specifically passed dynamic bending life tests should be prioritized.

4. Is flat cable suitable for high-speed signal transmission?

Answer: Yes. Due to the parallel arrangement of conductors and consistent spacing, flat cable has advantages in high-speed signal transmission (such as LVDS, HDMI, USB, and MIPI), effectively reducing signal crosstalk and timing differences. If used in high-speed scenarios, it is recommended to choose flat cable with a shielding layer to ensure signal integrity.

Conclusion

In simple terms, a flat cable is a type of cable that consists of multiple conductors arranged in parallel in a ribbon-like structure. Due to its advantages of space-saving, neat wiring, and stable signal transmission, it is widely used in various fields such as electronic devices, automobiles, industry, and healthcare. Different types of flat cables (such as ribbon cables, FFC, and FPC) each have their own characteristics, and users should consider factors such as electrical performance, flexibility, operating environment, and standard certifications when making a selection.

As a professional flat cable manufacturer, Linkwings provides customers with flat cable products and customized solutions that comply with international standards, ensuring safe and reliable connections every time.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In