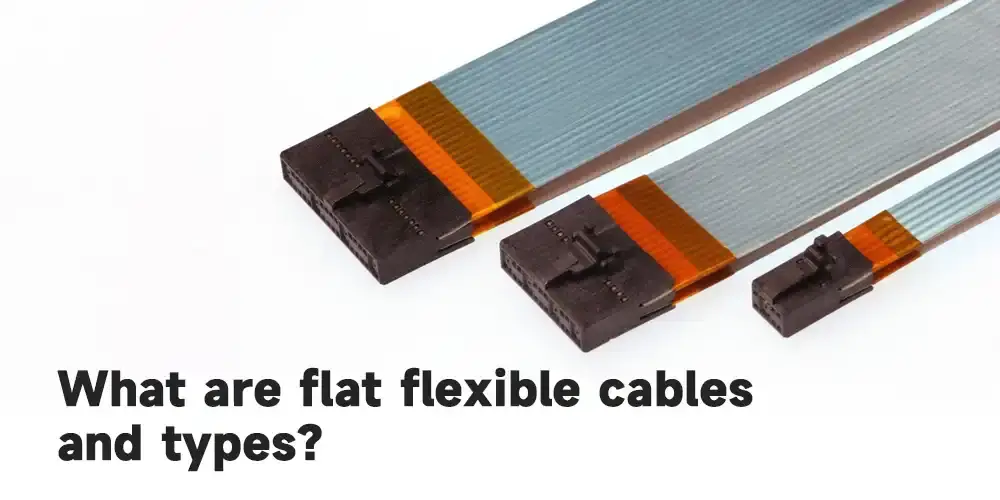

What Is Flexible Flat Cable? Flexible Flat Cable (FFC) is a lightweight, thin cable consisting of multiple copper conductors arranged in parallel and sandwiched between insulating films. It offers advantages such as excellent flexibility, neat wiring, and suitability for high-speed signal transmission. As a result, it is widely used in laptops, displays, automotive electronics, and medical devices.

As an experienced flat cable manufacturer, Linkwings will provide a comprehensive overview of FFC structure, advantages, application scenarios, and selection criteria in this article, helping you quickly understand and choose the appropriate solution.

What is a Flexible Flat Cable?

A Flexible Flat Cable (FFC) is a type of cable consisting of multiple parallel metal conductors sandwiched between insulating films. It has a ribbon-like shape with a thickness typically ranging from 0.1mm to 0.3mm, featuring lightweight, high flexibility, and neat wiring. Due to its uniformly arranged conductors and standardized spacing, FFC enables high-density, reliable electrical connections in electronic devices.

Compared to traditional Round Cable or Ribbon Cable, the distinctive features of FFC include:

- Lighter and thinner — takes up less space, suitable for ultra-thin electronic devices;

- More flexible — can be bent and folded to meet dynamic movement requirements;

- Higher precision — highly uniform conductor spacing (pitch), with common specifications including 0.5 mm, 1.0 mm, 1.25 mm, etc.

In practical applications, FFC is commonly found in internal connection locations of devices such as laptops, LCD displays, printers, in-vehicle displays, and medical equipment. It not only transmits low-frequency power but also supports high-speed data signals (such as LVDS, MIPI, and HDMI).

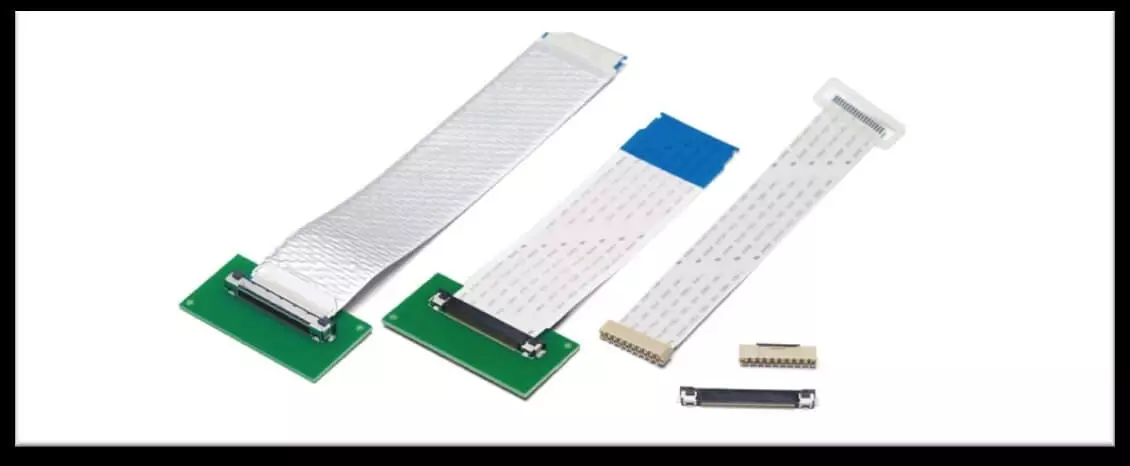

It is important to note that FFC is distinct from FPC (Flexible Printed Circuit). FFC is a standardized cable structure typically featuring single-layer conductors arranged in parallel, while FPC involves etching circuits onto a flexible substrate, enabling multi-layer designs and more complex routing. As a result, FFC is better suited for high-volume, standardized signal connections, whereas FPC is more oriented toward high-end customized applications.

Characteristics of Flexible Flat Cable

Flexible Flat Cable (FFC) is widely used in electronic devices, automobiles, and industrial systems because it combines light weight, flexibility, and excellent electrical performance. It has the following main characteristics:

1. Lightweight and space-saving

FFC typically has a thickness of only 0.1–0.3 mm, with conductors arranged compactly, significantly reducing wiring volume. This feature makes it ideal for internal connections in ultra-thin devices such as laptops, LCD displays, and smartphone modules.

2. Flexibility and bendability

FFC conductors are sandwiched between PET (polyester) or PI (polyimide) films, giving them excellent flexibility and enabling folding or bending in limited spaces.

- Static applications: such as connections between mainboards and daughterboards.

- Dynamic applications: such as printer carriages, industrial robots, and other moving parts. Some high-performance FFCs can withstand thousands to tens of thousands of repeated bends.

3. Standardized Pitch and Structure

A significant advantage of FFC is its highly standardized pitch (conductor spacing), with common specifications including 0.5mm, 1.0mm, 1.25mm, and 2.54mm.

- Smaller pitch → more suitable for precision electronics and high-speed signal transmission.

- Larger pitch → more suitable for power supply or applications with high mechanical strength requirements.

This standardized design facilitates mass production of FFCs and enables compatibility with interfaces such as ZIF (Zero Insertion Force connectors) and LIF (Low Insertion Force connectors).

4. Excellent electrical performance

- Low contact resistance: Ensures stable signal transmission.

- Low crosstalk: Conductors are arranged in parallel with uniform electrical paths, suitable for high-speed signals such as LVDS, MIPI, and HDMI.

- High consistency: Minimal signal transmission delay differences (low skew), beneficial for synchronizing multiple parallel signals.

5. Shielding and Interference Resistance

Some FFCs can be equipped with aluminum foil shielding layers or braided shielding layers for high-frequency or high-EMI environments. Shielded FFCs significantly reduce electromagnetic interference and are commonly used in automotive electronics and industrial automation.

6. Cost and Production Advantages

Compared to FPC (flexible printed circuit boards), FFCs have a simpler structure, mature manufacturing processes, and lower production costs, making them highly suitable for mass production and standardized applications.

Advantages and Disadvantages of Flexible Flat Cables

Flexible Flat Cable (FFC) is widely used in consumer electronics, automobiles, and industrial equipment due to its light weight, flexibility, and high-speed signal transmission capabilities. However, it is not a panacea and has its limitations. Below, we will conduct a comprehensive analysis from an engineering and application perspective.

Advantages

- Lightweight and space-saving: Typically 0.1–0.3 mm thick, suitable for compact devices such as laptops, displays, and smartphones.

- Flexibility and bendability: Can be folded or bent multiple times; some high-performance FFCs have a bend life of tens of thousands of times, suitable for dynamic applications.

- Standardized design: Pitch specifications are standardized (e.g., 0.5 mm, 1.0 mm, 1.25 mm), facilitating mass production and interface compatibility (e.g., ZIF/LIF connectors).

- Stable electrical performance: Conductors arranged in parallel → consistent signal paths → low crosstalk and low skew, suitable for high-speed signals such as LVDS, MIPI, and HDMI.

- Cost-effective: Compared to FPC (flexible printed circuit boards), it has a simpler structure, more mature manufacturing processes, and lower production costs, making it suitable for large-scale applications.

Disadvantages

- Limited current-carrying capacity: More suitable for low-current and signal transmission applications, not suitable for high-current or high-power applications.

- Low mechanical strength: The flat structure lacks outer sheath protection, resulting in poor tensile strength and abrasion resistance, making it unsuitable for harsh environments or frequent external forces.

- Limited environmental resistance: Standard FFC does not have waterproof, oil-resistant, or chemical corrosion-resistant capabilities, requiring specialized design for industrial or automotive environments.

- Lifespan considerations for dynamic applications: Although flexible, excessive bending radii or prolonged frequent movement may cause copper conductor fatigue or breakage.

- Shielding performance requires additional design: Standard FFCs do not include a shielding layer. In high EMI environments, custom shielded FFCs are required to prevent signal integrity issues.

Where Is FFC Used?

Flexible flat cables are used in a wide range of fields, from consumer electronics to automobiles, industrial automation, and medical equipment.

Their core values are:

- Lightweight and flexible → Suitable for devices with limited space

- Stable signal → Supports high-speed transmission

- Standardization and customization → Meets the needs of different industries

Application 1 : Consumer Electronics

Application scenarios: laptops, tablets, smartphones, printers, scanners, LCD displays.

- In these devices, space is limited and wiring is complex, requiring a cable that is both thin and lightweight while ensuring high-speed signal transmission.

- FFC is commonly used for connections between displays and motherboards, keyboards and control circuits, as well as moving components such as printer carriages.

Linkwings Solution: Offers high-flexibility FFC with 0.5mm/1.0mm pitch, supporting high-speed interfaces such as LVDS and MIPI. It has undergone bend life testing to ensure long-term stability in frequently moving applications.

Application 2 : Automotive Electronics

Application scenarios: central control display, in-vehicle cameras, instrument panels, entertainment systems, and ADAS (Advanced Driver Assistance Systems).

- The automotive electronics environment is characterized by high temperatures and frequent vibrations. Traditional round cables are complex to route, whereas the flat structure of FFCs is more suitable for routing in confined spaces.

- Especially in in-vehicle display and infotainment systems, FFCs have become the mainstream choice.

Linkwings Solution: Provides high-temperature resistant (-40°C to +125°C), shielded automotive-grade FFCs that meet ISO/TS 16949, UL, RoHS, and other standards, ensuring reliability in the harsh automotive environment.

Application 3 : Industrial Automation & Robotics

Application scenarios: industrial printers, robotic arms, automated equipment, and connections between sensors and control units.

- Industrial environments often involve oil contamination, dust, humidity, and frequent dynamic movements.

- FFC provides neat cabling and stable signal transmission between robot joints and automation modules.

Linkwings Solution: Customized FFC with oil-resistant and chemically corrosion-resistant sheathing, tested for over a million dynamic bending cycles, suitable for long-term high-frequency movements, ensuring signal stability and mechanical reliability.

Application 4 : Medical Devices

Application scenarios: imaging diagnostic instruments, patient monitoring equipment, surgical robots, and wearable medical devices.

- Medical devices require high-precision signal transmission and reliability, while also being compact in size with limited wiring space.

- For example, FFC/FPC is commonly used in the connection between ultrasound probes and main units, as well as in the circuit connections of monitors.

Linkwings Solution: Provides high-precision customized FFC/FPC solutions compliant with ISO 13485, RoHS, and REACH standards, and can utilize biocompatible materials to ensure safety and reliability in medical environments.

FAQs

1. Can Flexible Flat Cable be used for high-speed signal transmission?

Answer: Yes. FFC can effectively reduce crosstalk and signal delay differences (skew) because the conductors are arranged in parallel with consistent spacing. After adding a shielding layer, FFC can support high-speed interfaces such as LVDS, HDMI, and MIPI, and is commonly used in displays and multimedia devices.

2. What is the bending life of FFC?

Answer: Ordinary PVC/PET insulated FFC can withstand thousands of bends, while high-performance PI-based FFC can withstand tens of thousands or even millions of bends. The actual life depends on the bending radius and the usage environment. It is generally recommended that the bending radius be no less than 6 to 10 times the thickness of the cable.

3. What are the common pitch specifications for Flexible Flat Cables?

Answer: The pitch (conductor spacing) specifications for FFCs are highly standardized, with common specifications including 0.5mm, 1.0mm, 1.25mm, and 2.54mm. Among these:

- 0.5mm/1.0mm → Commonly used in precision electronics such as laptops and LCD displays.

- 1.25mm/2.54mm → Commonly used in industrial control systems, printers, and other equipment with high mechanical strength requirements.

4. Can Flexible Flat Cables be customized?

Answer: Yes. Common customization options include: pitch, number of conductors, length, shielding layer, high-temperature resistance, waterproofing, and chemical corrosion resistance. Linkwings offers both standardized FFC products and customized FFC solutions, designed and manufactured to meet the specific requirements of different application scenarios.

Conclusion

Through this article, you should now have a clear understanding of what a flexible flat cable (FFC) is. It is a lightweight, thin cable composed of parallel conductors and an insulating layer, offering advantages such as space-saving design, excellent flexibility, and stable signal transmission. While FFCs have certain limitations in terms of current-carrying capacity and environmental adaptability, these can be effectively addressed through proper selection or customization to meet the needs of various applications.

As a professional flat cable manufacturer, Linkwings not only provides standardized FFC products compliant with international standards but also develops customized solutions tailored to customer needs, ensuring that every connection is safe, reliable, and long-term stable.

What is the Difference Between Cat5e and Cat6 RJ45 Connectors?

Table of Contents Wh

What is RJ45 Connector?

Table of Contents In

Top 10 LVDS Cable Manufacturers in World 2026

Table of Contents In

How to Check Lvds Cable?

Table of Contents In